Wend

Established Member

Hi folks,

I recently used an eclipse-style honing guide for my plane blades for the first time, and found it worked a lot better than my previous sharpening attempts, so I thought I'd try it with my chisels too.

However, this chisel is quite wedge-shaped

and is 9.1mm at the handle end

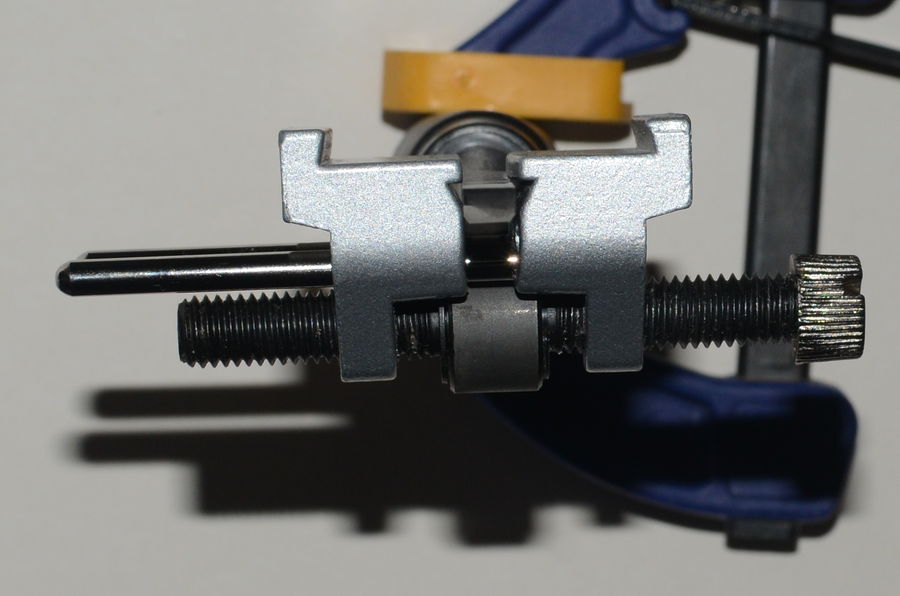

This means that, at the 40mm protrusion, it doesn't fit between the chisel notch and the bars that hold the sides of the guide together.

These were bought as cheap DIY chisels decades ago, so are they thicker than chisels designed for wood working? Would filing the top face (by which I mean, the face pointing down in the photos) to make them fit the guide be a crazy thing to do? And would it take forever?

Should I just buy some better chisels?

Or am I missing a better solution / using the honing guide wrong?

Thanks!

Wend

I recently used an eclipse-style honing guide for my plane blades for the first time, and found it worked a lot better than my previous sharpening attempts, so I thought I'd try it with my chisels too.

However, this chisel is quite wedge-shaped

and is 9.1mm at the handle end

This means that, at the 40mm protrusion, it doesn't fit between the chisel notch and the bars that hold the sides of the guide together.

These were bought as cheap DIY chisels decades ago, so are they thicker than chisels designed for wood working? Would filing the top face (by which I mean, the face pointing down in the photos) to make them fit the guide be a crazy thing to do? And would it take forever?

Should I just buy some better chisels?

Or am I missing a better solution / using the honing guide wrong?

Thanks!

Wend