woodbloke

Established Member

I recently got hold of a Charnwood W650 table saw, a nice piece of kit but in need (as with much stuff from t'Orient) of some minor and inexpensive fettling to improve performance...close scrutiny of the pic will reveal that there are one or two non-standard bits and bobs on the slider as well as a zero tol insert plate:

Those with super keen eyeballs will note that the rhs extension table has been disposed off:

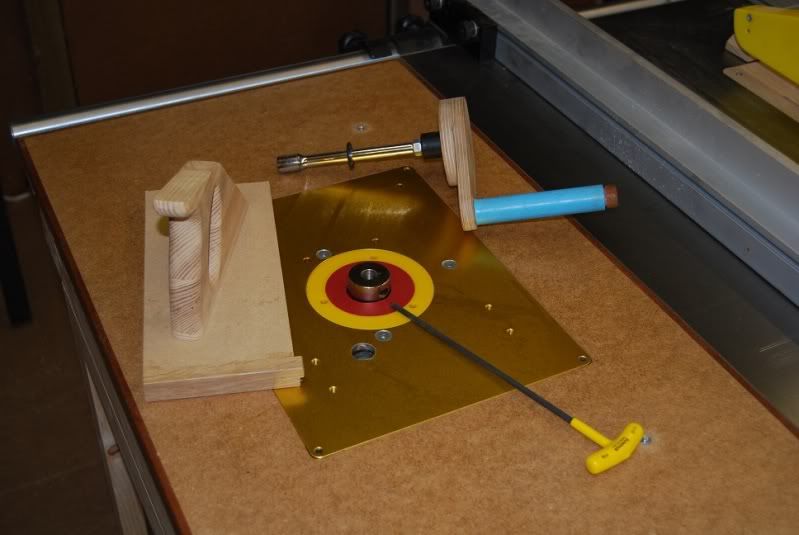

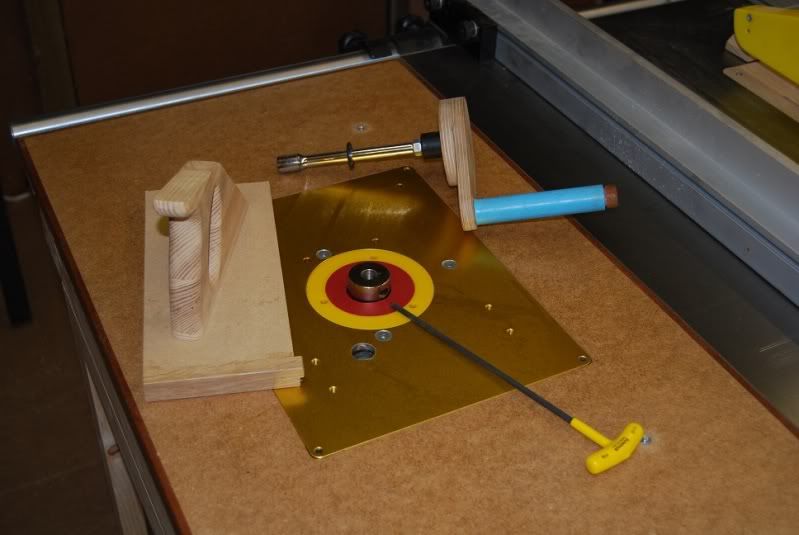

...and in it's place is router table. The top is three layers of decent quality 8mm mdf that I salvaged from B&Poo (strange, but it's much better than the normal stuff they stock) last Saturday, for the princely sum of £1, with a piece of oil-tempered hardboard for a surface, all squished in the AirPress, then lipped with some 6mm mahogany. There's a substantial softwood frame underneath glued to the top which ensures that it sits flat. It fits onto the table on three sides with a series of 8mm bolts, with a new piece of 20mm steel tubing seen in the pic (closest) The side frame is Domino'd together \ / the first time I've used it to make anything and has a couple of self-adjusting leveling feet, with the NVR bolted to it underneath the table. The router plate is the Axminster:

/ the first time I've used it to make anything and has a couple of self-adjusting leveling feet, with the NVR bolted to it underneath the table. The router plate is the Axminster:

...aluminium one which was really easy to insert and level of, sitting on four 15mm dowels in each corner. There's an Extreme Extension in the plate which is just about the best thing (in my view) that you can ever fit to a router table. The router is a T11 with the raising handle shown. There's also no track. It's a commonly held fallacy that you need a track in a router table surface...you don't:

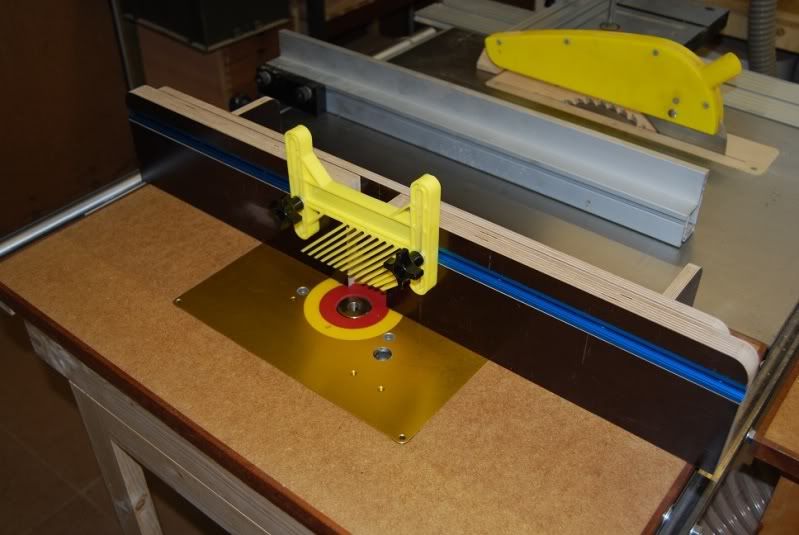

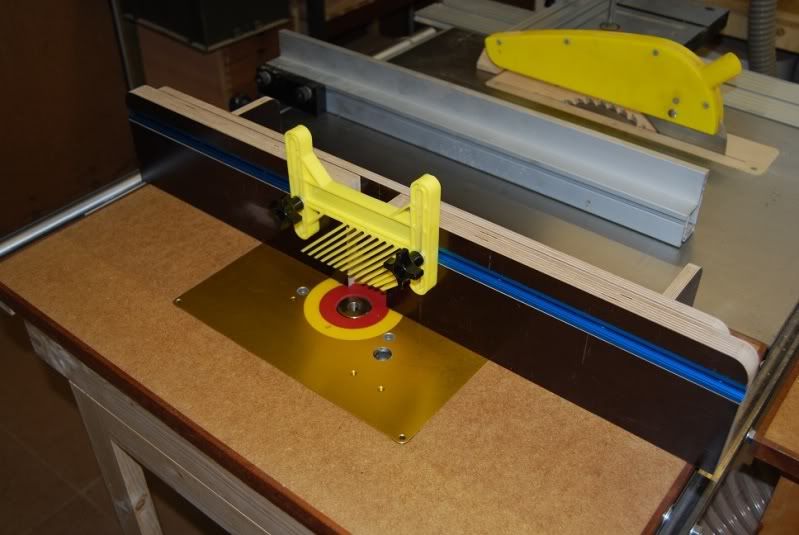

...because if you use the angled push block (note that the handle is skewed inwards) shown previously against the fence, the work is automatically held against it. The material for the fence is 12mm melamine faced birch ply and was provided by Bob9fingers at one of the Bash's that we had at Wilton last year, so many thanks indeed for that Bob. All the bits n'pieces for the fence came from the Axminster jig making kit which is a great resource for this sort of thing, except that all the threads are Whitworth :evil: and so not compatible with other Metric fixings. The 'T' track is Axminsters own blue extruded aluminium stuff. The featherboard had to have some fettling done as well as the original slots were too narrow and had to be milled out a tad on the table. The constuction at the rear of the fence:

...shows the various knobs, with the dust port and a couple of bracing pieces at each end. Construction is using small biscuits throughout (knife line marks can clearly be seen) with the top of the dust port screwed in place - Rob :ho2 :deer :deer

Those with super keen eyeballs will note that the rhs extension table has been disposed off:

...and in it's place is router table. The top is three layers of decent quality 8mm mdf that I salvaged from B&Poo (strange, but it's much better than the normal stuff they stock) last Saturday, for the princely sum of £1, with a piece of oil-tempered hardboard for a surface, all squished in the AirPress, then lipped with some 6mm mahogany. There's a substantial softwood frame underneath glued to the top which ensures that it sits flat. It fits onto the table on three sides with a series of 8mm bolts, with a new piece of 20mm steel tubing seen in the pic (closest) The side frame is Domino'd together \

...aluminium one which was really easy to insert and level of, sitting on four 15mm dowels in each corner. There's an Extreme Extension in the plate which is just about the best thing (in my view) that you can ever fit to a router table. The router is a T11 with the raising handle shown. There's also no track. It's a commonly held fallacy that you need a track in a router table surface...you don't:

...because if you use the angled push block (note that the handle is skewed inwards) shown previously against the fence, the work is automatically held against it. The material for the fence is 12mm melamine faced birch ply and was provided by Bob9fingers at one of the Bash's that we had at Wilton last year, so many thanks indeed for that Bob. All the bits n'pieces for the fence came from the Axminster jig making kit which is a great resource for this sort of thing, except that all the threads are Whitworth :evil: and so not compatible with other Metric fixings. The 'T' track is Axminsters own blue extruded aluminium stuff. The featherboard had to have some fettling done as well as the original slots were too narrow and had to be milled out a tad on the table. The constuction at the rear of the fence:

...shows the various knobs, with the dust port and a couple of bracing pieces at each end. Construction is using small biscuits throughout (knife line marks can clearly be seen) with the top of the dust port screwed in place - Rob :ho2 :deer :deer