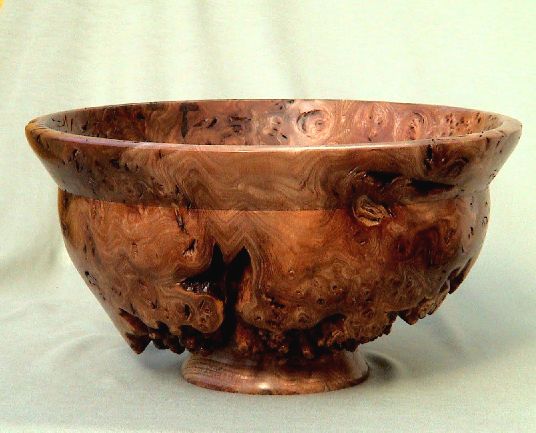

I've just completed an elm burr bowl and have been seeking guidance on finishing. Mark Baker's book "Woodturning Projects" does a number of burr objects which he uses oils to finish and then burnishes with something I'd not heard of - 'EEE-Ultrashine'.

I see that Toolpost stock this - comes from Austalia. Is it worthwhile investing in some or are other burnishing products just as good ?

Rob

I see that Toolpost stock this - comes from Austalia. Is it worthwhile investing in some or are other burnishing products just as good ?

Rob