Chip shop

Established Member

OK, this is a bit boring, but it is something that others might learn from.

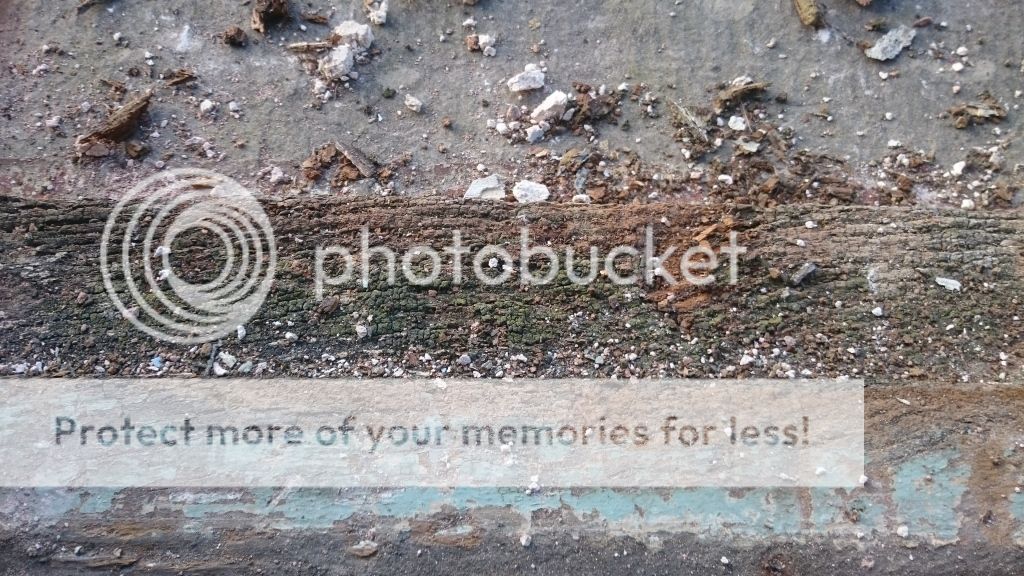

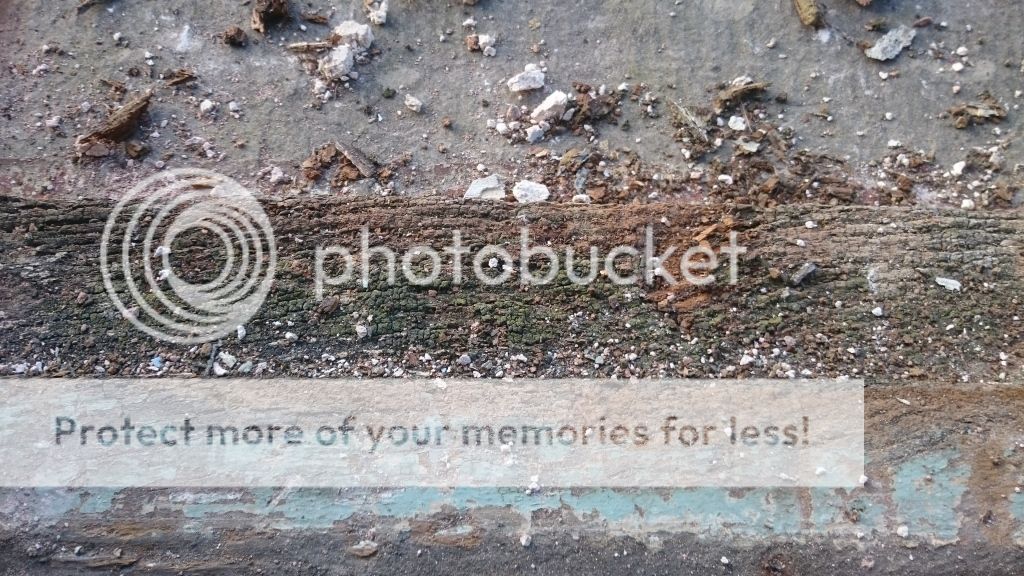

Got to site this morning for a cut out, replace and paint job and found something that highlights the problems of oak cills. Oak don't take paint well. It's a box sash window made of pine, with an oak cill which is buggered. As a result the pulley stiles are goosed also.

Chip off the plaster inside:

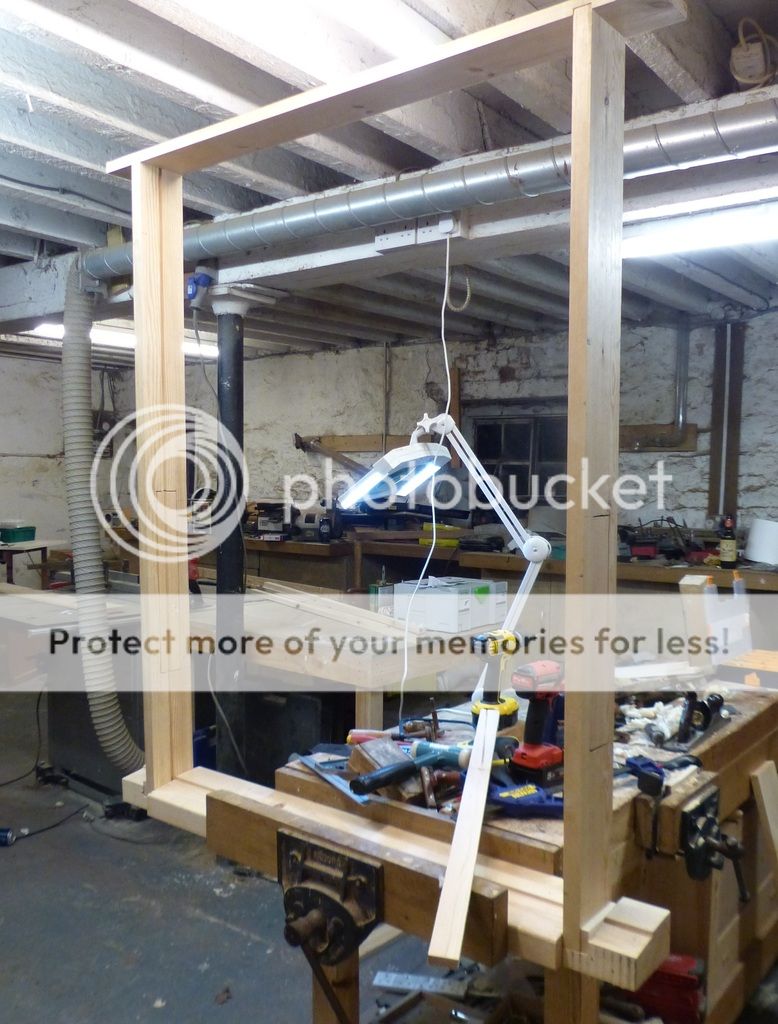

Break apart the window by prizing away the staff bead and parting bead with a chisel (they're only nailed into place, so don't worry breaking stuff). You should end up with something like this:

Back in the workshop I mark out...badly:

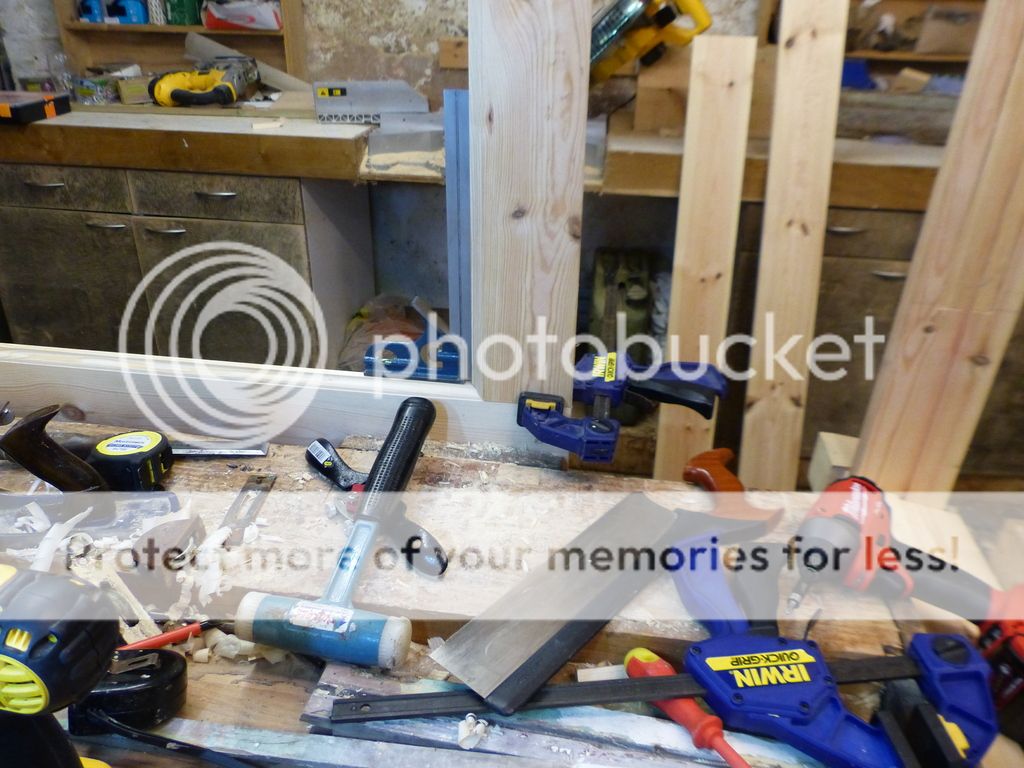

Make the housings for the pulley stiles(these will be wedged into place)...

Then get to work on the cill.

Got to site this morning for a cut out, replace and paint job and found something that highlights the problems of oak cills. Oak don't take paint well. It's a box sash window made of pine, with an oak cill which is buggered. As a result the pulley stiles are goosed also.

Chip off the plaster inside:

Break apart the window by prizing away the staff bead and parting bead with a chisel (they're only nailed into place, so don't worry breaking stuff). You should end up with something like this:

Back in the workshop I mark out...badly:

Make the housings for the pulley stiles(these will be wedged into place)...

Then get to work on the cill.