Hi

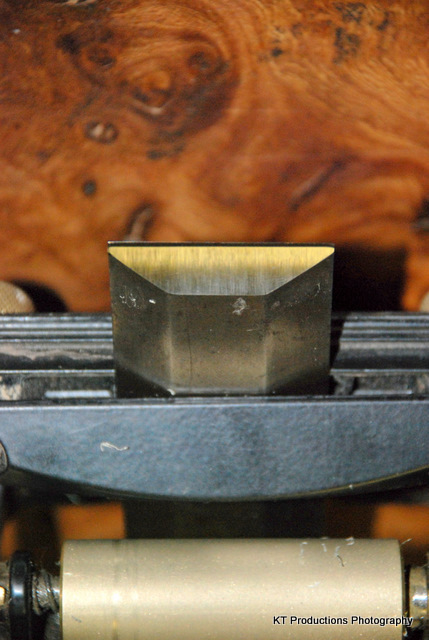

I have bought a bench grinder but it's got no tool rests. Anyone got any good designs for home made rests. I'm thinking this sort of thing, but home made

http://www.axminster.co.uk/veritas-veri ... prod22615/

I seem to remember seeing one on here years ago but can't find it now. Please post yours so I have a few ideas

Thanks

Mark

I have bought a bench grinder but it's got no tool rests. Anyone got any good designs for home made rests. I'm thinking this sort of thing, but home made

http://www.axminster.co.uk/veritas-veri ... prod22615/

I seem to remember seeing one on here years ago but can't find it now. Please post yours so I have a few ideas

Thanks

Mark