I too have tried to find ceramic guide blocks for my Kity 613 without success so, I thought that I would try and make some.

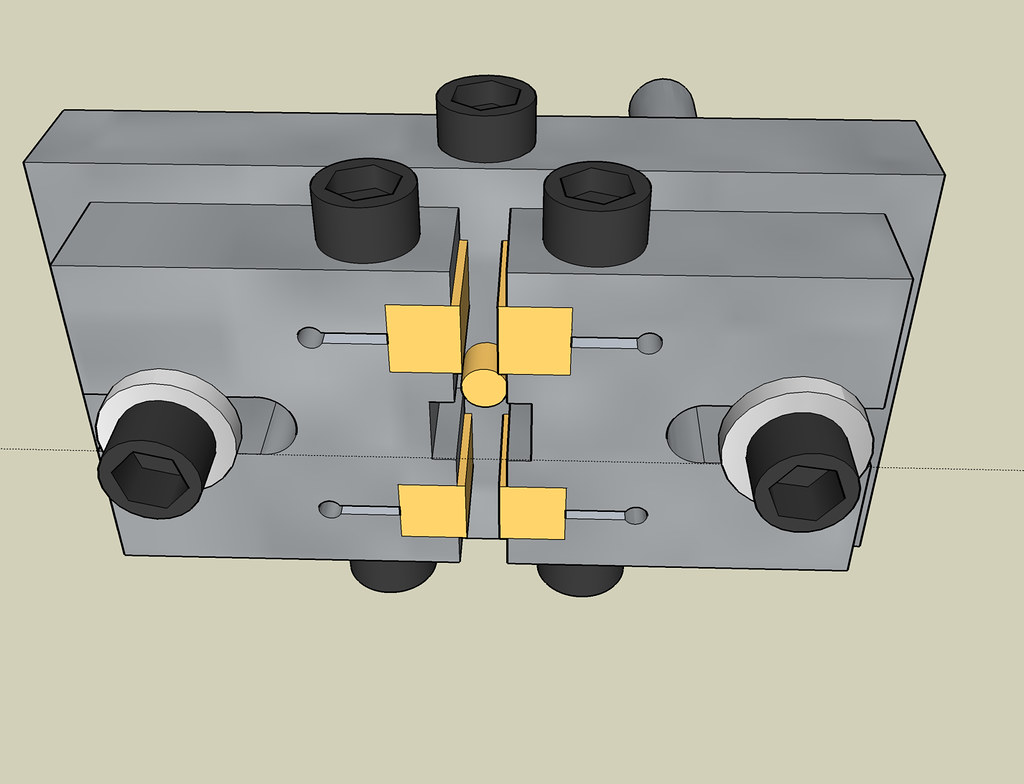

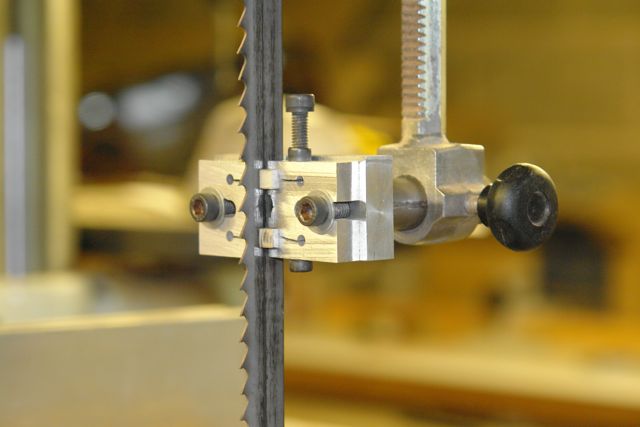

The drawing and photo should be self explanatory for anyone with access to a metal lathe.

The ceramic blocks and rod were Spyderco ceramic files which were cut up using a thin diamond slitting disc from Eternal Tools.

I was worried that, being files, they would abrade the blade but they are very fine and the square guides only lightly touch the blade so there is no problem there,The rear ceramic rod does suffer some wear (about 0.1mm groove after extensive use) but it would take forever to destroy a blade or itself.

The results were very good :-

Easy to set up, much quieter than the original guides, just as I had hoped.

The new guides plus using a Dragon 3tpi M42 blade have transformed my bandsaw from an essential but rough tool into a precision instrument.

As a newcomer to this forum I am delighted with all the useful information.

I hope that this contribution will be of use to someone.