This bit belonged to my great grandfather, I assume it is a screwdriver bit for use in a brace. It's made by Marples and the end appears to have been hammered at some point (I think it may have been "repurposed" at some stage in its life!). Was this bit designed for use in an older type brace (given that the shank is a tapered and square in cross section), rather than the more conventional 2 or 3 jaw brace I'm familiar with? Any info appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Any info on this old brace bit?

- Thread starter carpenteire2009

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I think you are right; screwdriver bits to go in a brace were quite common, and the tapered square shank was the standard for many years. It's a very practical option and can be just as fast as a cordless screwdriver, with very good control. Your main problem now will be finding slotted screws; but a brace with a simple two-jaw crocodile chuck will also grip a hex shank cordless screwdriver bit neatly - and the batteries don't run out.

Your specimen looks quite a broad blade, so would be of limited use nowadays - so you could copy what I have done and set it in a handle, making a screwdriver which is a proper fit for the big cap screw on a plane iron.

Your specimen looks quite a broad blade, so would be of limited use nowadays - so you could copy what I have done and set it in a handle, making a screwdriver which is a proper fit for the big cap screw on a plane iron.

bugbear

Established Member

It looks like someone has "sharpened" the screwdriver, which would need regrinding, if you intended to use it again.

BugBear

BugBear

Yes, the tip has been crudely ground at some stage; I like the suggestion for putting a handle on it, thanks guys!

jimi43

Established Member

Nice! I can just see W.Marples shamrocks there can't I?

Quite an early one then.

Jim

Quite an early one then.

Jim

Fromey

Established Member

On the subject of brace bits, does anyone know where you can buy new center bits? I found a box of them in an antiques store recently, but they were asking silly money for them (and they would have needed a lot of fettling).

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£238.91

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£16.59

£25.00

Woodworking Joinery by Hand: Innovative Techniques Using Japanese Saws and Jigs

Amazon.co.uk

£12.50 (£1,250.00 / kg)

£14.45 (£1,445.00 / kg)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

Fromey":3mklmbsd said:On the subject of brace bits, does anyone know where you can buy new center bits? I found a box of them in an antiques store recently, but they were asking silly money for them (and they would have needed a lot of fettling).

I don't know of anyone making them now.

Most of mine came from eBay, where they are fairly common in the Collectables>Tools>woodworking category. High postage is generally the deterrent, so look for lots local to you that you can collect.

If you need a particular size, and ever get up to Bristol, Bristol Design have a good selection to rummage through.

bugbear

Established Member

Fromey":11fvtums said:On the subject of brace bits, does anyone know where you can buy new center bits? I found a box of them in an antiques store recently, but they were asking silly money for them (and they would have needed a lot of fettling).

Most specialist tool dealers have a box of 'em, if they haven't thrown them out.

Not expensive.

Generalist antique dealers seldom have the "right" price on tools. They vary all over the place, by a long way, both up and down.

I'm always fascinated by antique dealers who can happily "put a price" on items they can't identify!

BugBear

toolsntat

Yep, I collect tools and tat

Not sure about the tip needing sorting, as all the the ones I have are ground down to the point leaving a little flat in the same way as yours....

Got a close up shot of that area :?:

Cheers

Andy

Got a close up shot of that area :?:

Cheers

Andy

I've put a stock beech (file) handle on the bit, pic below. In answer to your queries, yes the blade does feature the Marples "shamrock" logo. The tip is crudely ground but does feature a small flat on the tip, unfortunately my camera won't allow me to get a good close up. I might clean this up on the Tormek.

Attachments

jimi43

Established Member

I'd clean it up flat....on some paper on glass....the Tormek will give it a concave bevel and I am of the opinion that it just doesn't look right on a screwdriver....but I don't want to open that can of worms up..... :mrgreen:

Jimi

Jimi

bugbear

Established Member

jimi43":279awfnf said:I'd clean it up flat....on some paper on glass....the Tormek will give it a concave bevel and I am of the opinion that it just doesn't look right on a screwdriver....but I don't want to open that can of worms up..... :mrgreen:

Too late - you just did! Concave screwdriver tips for ever! Death to the unbelievers!

BugBear

jimi43

Established Member

bugbear":3lhlq4i9 said:jimi43":3lhlq4i9 said:I'd clean it up flat....on some paper on glass....the Tormek will give it a concave bevel and I am of the opinion that it just doesn't look right on a screwdriver....but I don't want to open that can of worms up..... :mrgreen:

Too late - you just did! Concave screwdriver tips for ever! Death to the unbelievers!

BugBear

Oh deary me.... (homer)

DOH!!! :mrgreen:

Jim

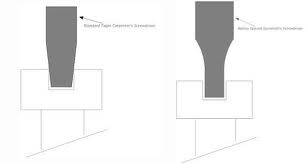

I have several of them and use them in My braces regularly, they are marvellous for removing slotted screws from door hinges and similar as you can put a tremendous amount of pressure on the brace pad to prevent the bit camming out of the screw slot and damaging it, a round disc of ply approx 6" in diameter with a dimple in the centre to take the brace pad helps to put pressure on with your stomach whilst turning the screw, very few screws can resist that, however tight or rusted. Grind it hollow so that the very tip is square and has parallel sides, (find a screw with a head the same diameter as the blade width and make the blade just thin enough to fit tightly into the slot, this will help to avoid the problem of cam out, ie the blade riding up the sides of the slot.

The picture on the right is the way to do it

Regards

Plover

The picture on the right is the way to do it

Regards

Plover

Attachments

Great info there guys, I like a hollow grind myself- may not look traditional but it is the most efficient and effective grind for this purpose!

bosshogg

Established Member

plover22":3254hj0t said:I have several of them and use them in My braces regularly, they are marvellous for removing slotted screws from door hinges and similar as you can put a tremendous amount of pressure on the brace pad to prevent the bit camming out of the screw slot and damaging it, a round disc of ply approx 6" in diameter with a dimple in the centre to take the brace pad helps to put pressure on with your stomach whilst turning the screw, very few screws can resist that, however tight or rusted. Grind it hollow so that the very tip is square and has parallel sides, (find a screw with a head the same diameter as the blade width and make the blade just thin enough to fit tightly into the slot, this will help to avoid the problem of cam out, ie the blade riding up the sides of the slot.

The picture on the right is the way to do it

Regards

Plover

Reminds me of my apprentice days, soon as I bought my bit and brace one of my journeyman asked me to try my new bit in a stuck screw, in a steel cast, machine moulding plate...You guest it, the screw head was part of the casting, but as the cocky young invincible lad I was, I fell for it - hook - line - and sinker #-o ...bosshogg

Similar threads

- Replies

- 151

- Views

- 6K

- Replies

- 39

- Views

- 2K

- Replies

- 9

- Views

- 3K