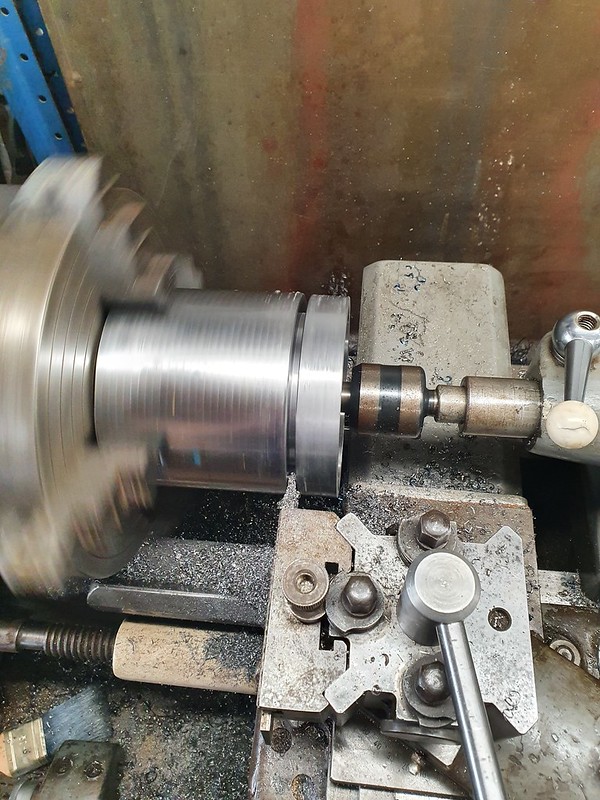

I would try to get a tailstock live centre into that chunk. All very well centering the 4-jaw but that only centres where your indicator is. The bar can easily be a bit skewed, especially with a heavy chunk.

The classic way to do it is, off the lathe, scribe the centre using an engineers' square, using the bit with the V jaws. The rule should be on a diameter. Do this a few times at different start points and you can find the centre quite accurately. Pop in a punch then put it on a pillar drill and drill out with a centre drill. Then you can get one end quite accurately in the tailstock while you fiddle about with the 4-jaw.

The classic way to do it is, off the lathe, scribe the centre using an engineers' square, using the bit with the V jaws. The rule should be on a diameter. Do this a few times at different start points and you can find the centre quite accurately. Pop in a punch then put it on a pillar drill and drill out with a centre drill. Then you can get one end quite accurately in the tailstock while you fiddle about with the 4-jaw.