Derek Cohen (Perth Oz)

Established Member

I wanted a tool tray for my bench. Yes, really. However I did not want one that would fill with shavings, or become an obstruction when planing or clamping. It could not be in the middle or at the side of the bench.

I had this idea when designing the bench that I would build a tray and, instead, attach it to the wall. During the course of my research, I also came across a photo of Chris Schwarz' tool-rack-across-the-window. This gave me an additional idea.

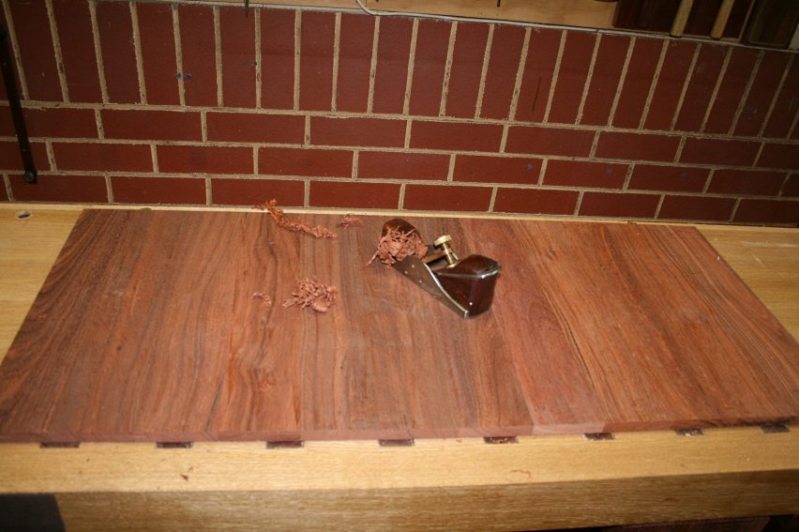

When I declared the bench completed, this is the box I built for part of the tool tray ...

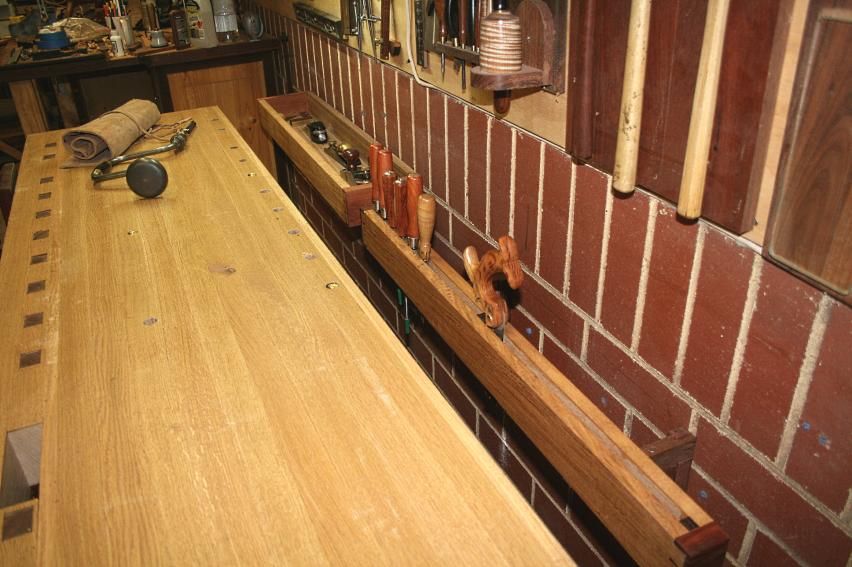

Here is the bench now with the completed tool trays - yes, plural ... there are two trays.

The first tray was attached to the wall so ...

The second was placed in line with this one, to its right ...

This tray is essentially a long slot, with the left side having dividers for chisels (these are adjustable for size) ...

The other half has space for backsaws. While i have a saw till, the slotted tray is simply to hold tools that would otherwise take up space on the bench.

The top of the tool trays are set a fraction below the top of the bench. When I need to plane across the bench, either the trays will be kept clear, or the bench can be pulled further back from the wall. At this stage there is enough clear room to work across the bench, and also to access the tools in the tray and on the wall.

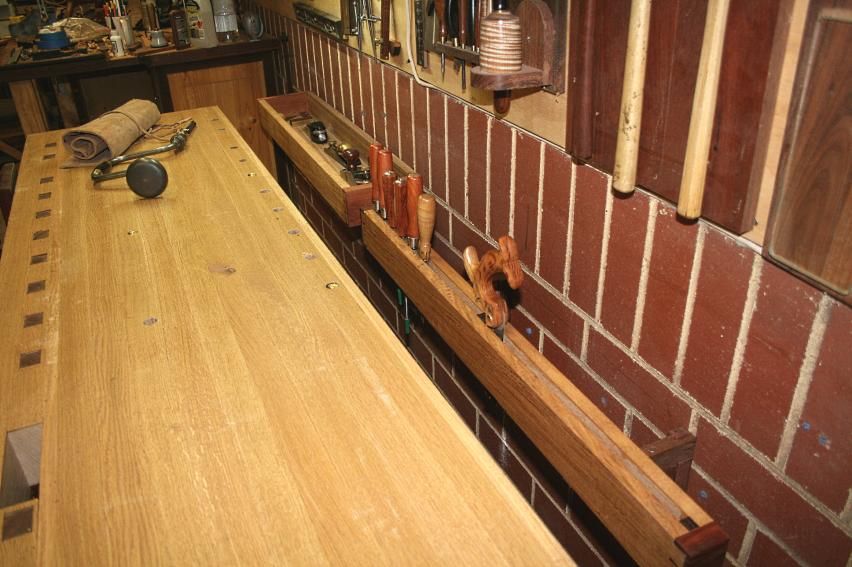

I then found a purpose for the "space" behind the slotted tray. This was not planned, but helps more than you can imagine.

One of the planes that "floats" around the shop is my 36" jointer. I just have no place to park it permanently. It takes up this empty surface, then that empty surface ... getting moved around all the time.

Now it has a home ...

Just for reference, that blade (by Berg) is 3" wide.

Lastly, the wood is Tasmanian Oak, often also called Tasmanian Ash. It is not a true oak, but a eucalypt (gum). It is one of the cheaper timbers around, and medium hard - about the same density as European Oak but has a little more interlocking in the grain. It is relatively cheap and when I need something for simple projects I go along to the local hardware shop (Bunnings) and buy a few lengths off the rack. They do not care about figure, etc. The boards are destined for DIY home repairs. The irony is that a lot of it comes quarter sawn. Very occasionally I find some that is curly, and grab it. It can be quite beautiful and would be wasted cut up and nailed together as a kennel.

Regards from Perth

Derek

I had this idea when designing the bench that I would build a tray and, instead, attach it to the wall. During the course of my research, I also came across a photo of Chris Schwarz' tool-rack-across-the-window. This gave me an additional idea.

When I declared the bench completed, this is the box I built for part of the tool tray ...

Here is the bench now with the completed tool trays - yes, plural ... there are two trays.

The first tray was attached to the wall so ...

The second was placed in line with this one, to its right ...

This tray is essentially a long slot, with the left side having dividers for chisels (these are adjustable for size) ...

The other half has space for backsaws. While i have a saw till, the slotted tray is simply to hold tools that would otherwise take up space on the bench.

The top of the tool trays are set a fraction below the top of the bench. When I need to plane across the bench, either the trays will be kept clear, or the bench can be pulled further back from the wall. At this stage there is enough clear room to work across the bench, and also to access the tools in the tray and on the wall.

I then found a purpose for the "space" behind the slotted tray. This was not planned, but helps more than you can imagine.

One of the planes that "floats" around the shop is my 36" jointer. I just have no place to park it permanently. It takes up this empty surface, then that empty surface ... getting moved around all the time.

Now it has a home ...

Just for reference, that blade (by Berg) is 3" wide.

Lastly, the wood is Tasmanian Oak, often also called Tasmanian Ash. It is not a true oak, but a eucalypt (gum). It is one of the cheaper timbers around, and medium hard - about the same density as European Oak but has a little more interlocking in the grain. It is relatively cheap and when I need something for simple projects I go along to the local hardware shop (Bunnings) and buy a few lengths off the rack. They do not care about figure, etc. The boards are destined for DIY home repairs. The irony is that a lot of it comes quarter sawn. Very occasionally I find some that is curly, and grab it. It can be quite beautiful and would be wasted cut up and nailed together as a kennel.

Regards from Perth

Derek