MrDavidRoberts

Established Member

- Joined

- 23 Dec 2016

- Messages

- 388

- Reaction score

- 2

My setup currently is a 400 & 1000 Grit diamond stones , after that I give a better edge using Autosol paste buttered on a good flat hardwood (that's what I already had) , the results are very OK!

However, I want to play around and I have an OCD around achieving the best I can I have a lot of time on my hands and I want to achieve the best edge one can possibly get just for the heck of it.

I have a lot of time on my hands and I want to achieve the best edge one can possibly get just for the heck of it.

Which pastes in what succession would you recommend to achieve the best possible sharpness one can get after coming from a 1000 grit diamond?

Although the autosol gives rather ok results, I'm not really sure if it's designed to be used as plane blade sharpener.

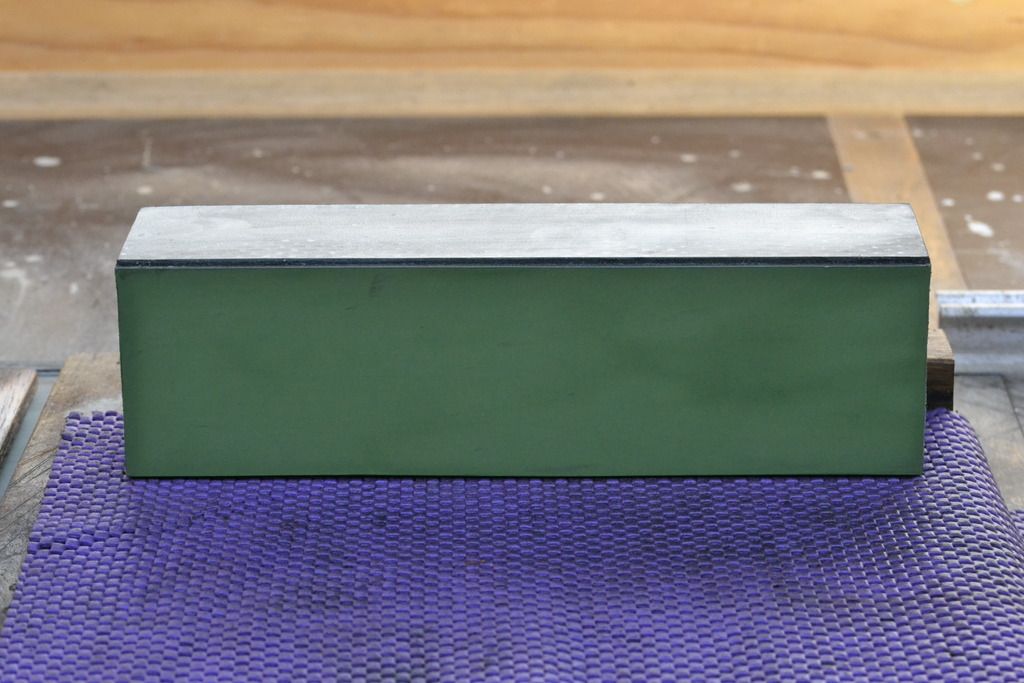

After doing some research I wanted to try myself to get a bit of the Green Paste ( Chromium oxide) and after that To finish the last step using the red JEWELLERS Rouge paste (Irod Oxide).

However I'm sure there's a better combo... Would be cool if someone could share his methods/steps.

However, I want to play around and I have an OCD around achieving the best I can

Which pastes in what succession would you recommend to achieve the best possible sharpness one can get after coming from a 1000 grit diamond?

Although the autosol gives rather ok results, I'm not really sure if it's designed to be used as plane blade sharpener.

After doing some research I wanted to try myself to get a bit of the Green Paste ( Chromium oxide) and after that To finish the last step using the red JEWELLERS Rouge paste (Irod Oxide).

However I'm sure there's a better combo... Would be cool if someone could share his methods/steps.