wallace

Established Member

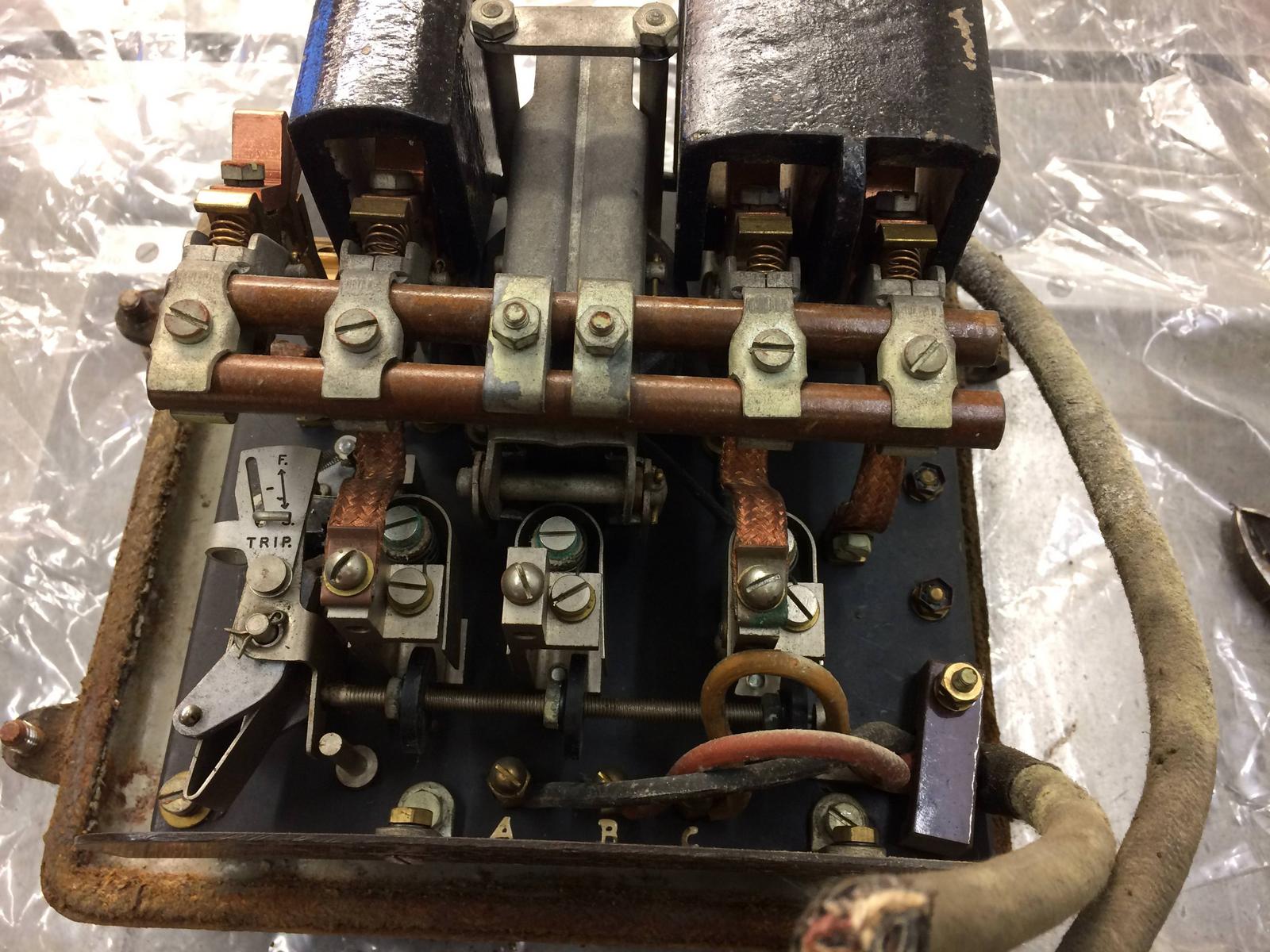

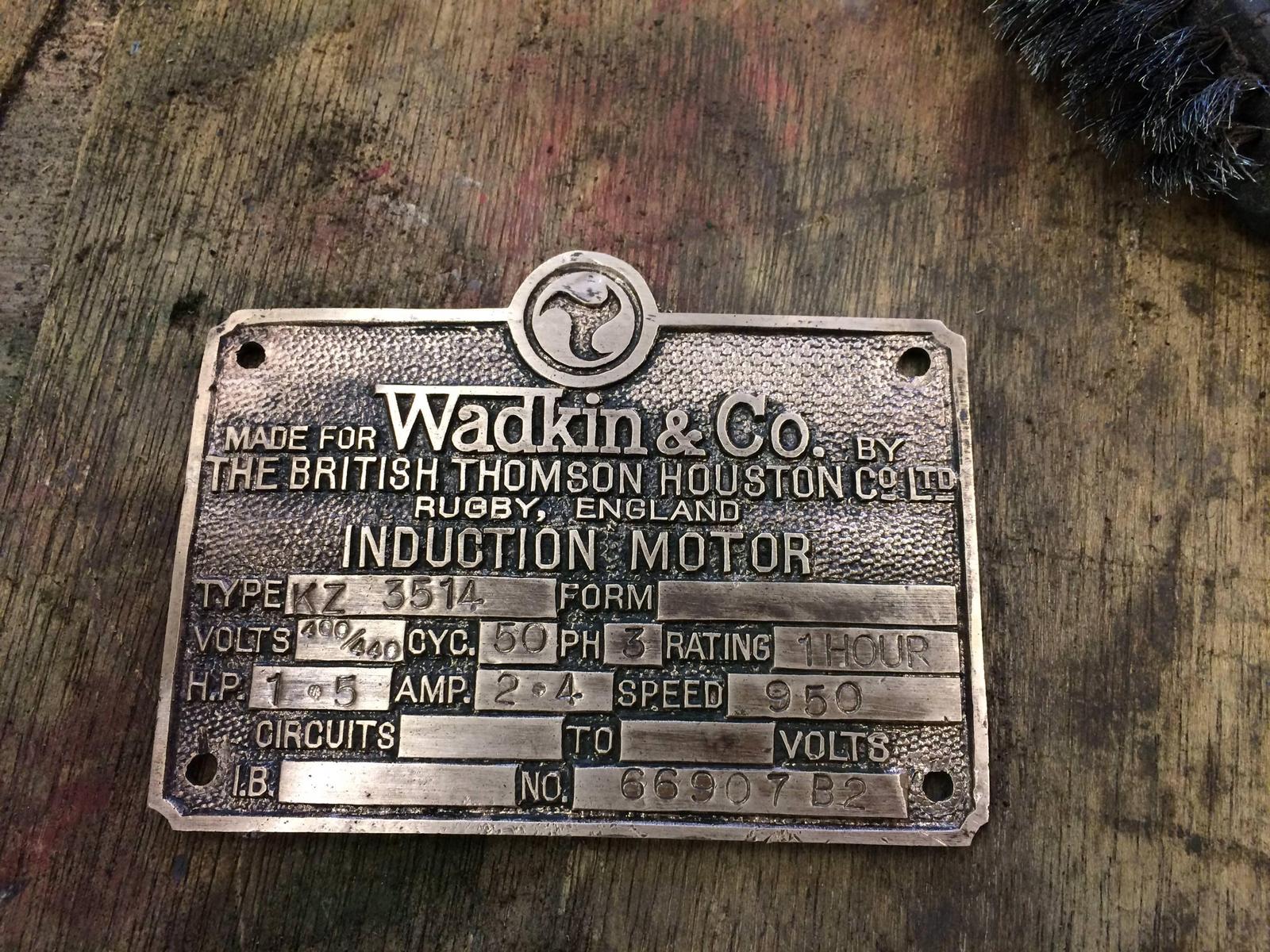

Its been a whole year since I started a machine so I thought its about time, This one dates from 1936 and is in rough but very complete condition. It has its original compound slide/carriage and even a nice 4 jaw chuck

One must remember check height restrictions and fluorescent tubes when entering the workshop, they don't half make a pop when hit

One must remember check height restrictions and fluorescent tubes when entering the workshop, they don't half make a pop when hit