Tim, the Wadkin fences are designed to be SLIGHTLY out to avoid released stresses in cut wood pinching the blade, causing kickback, BUT......check your saw has its top parallel to the blade? As in check mitre guage channel is same distance from a (fully raised) blade rear tooth as it is to a front tooth. If these two dimensions are identical, gnat's todger and all that, means top is where it should be. If the two values are different, look up inside the casing from the motor aperture, loosen off the four nuts holding the top on its studs and use a rubber persuader to nudge the top into parallel with the blade. Job done, tighten nuts.

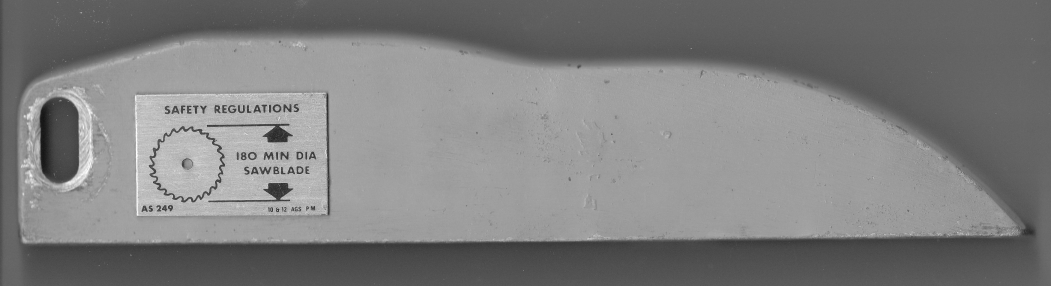

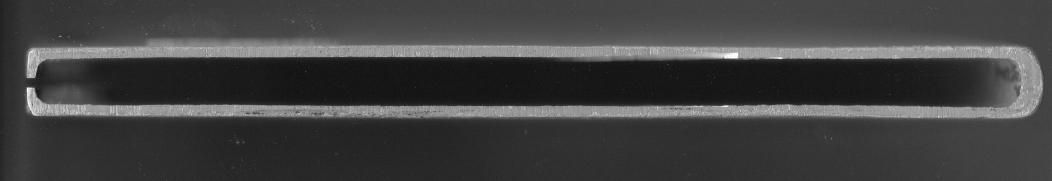

Still wonky? Then I suggest you look carefully at the fence bolts on the front of your machine, rail may be skewed? Need to measure the distance of fence rail to saw top edge all along it. Remedial action if distances vary: washers to re-establish fence rail parallelism to the saw top edge. Fudge and footer, fettle and cuss....

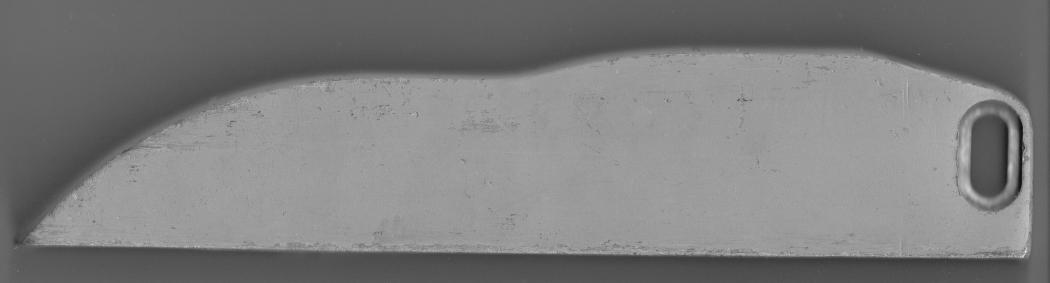

Come back if you want more, I've got a few photos of mine disassembled.

Sam