gasman

Established Member

Been a long while since I posted a WIP. Mostly I have been doing stuff round the house but I am now faced with a bit of a problem. We have a mahogany dining table which looks out of place in our dining room as the other furniture is all light-coloured. My wife has never liked the table - it was made by my late father so has sentimental value to me but it is very big and I do not think was his best piece. It definitely looks out of place in the room where it is.

Anyway, I think it is going to have to go but I have come up with a possible solution which might be acceptable to my dear old Dad up there in heaven, to my mother, to my wife and to me.... I am going to turn it into a Victorian drum table similar to this one which should look much more in keeping with other furniture in the house.

The table top was 78x38 inches and nearly an inch think!

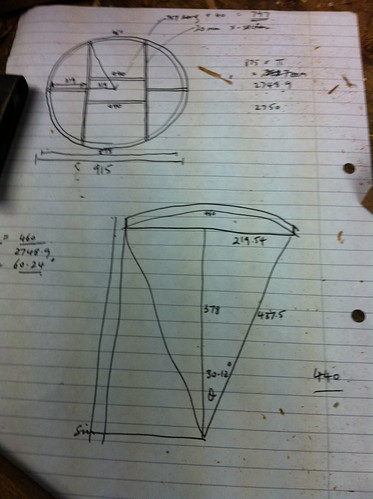

I have started work and will upload more later. There are no plans I can find for this sort of thing so it is all going to have to be made up as I go along.

Also I need to find some special touches and secrets to put into it.

Just ordered some brass table leg 'cups' from Martins and have cut my laminating press to a 36 inch radius.

More to follow

Mark

Can't work out why the photos are not working - could it be that they are grabbed from the internet and not my own photos?

Anyway, I think it is going to have to go but I have come up with a possible solution which might be acceptable to my dear old Dad up there in heaven, to my mother, to my wife and to me.... I am going to turn it into a Victorian drum table similar to this one which should look much more in keeping with other furniture in the house.

The table top was 78x38 inches and nearly an inch think!

I have started work and will upload more later. There are no plans I can find for this sort of thing so it is all going to have to be made up as I go along.

Also I need to find some special touches and secrets to put into it.

Just ordered some brass table leg 'cups' from Martins and have cut my laminating press to a 36 inch radius.

More to follow

Mark

Can't work out why the photos are not working - could it be that they are grabbed from the internet and not my own photos?