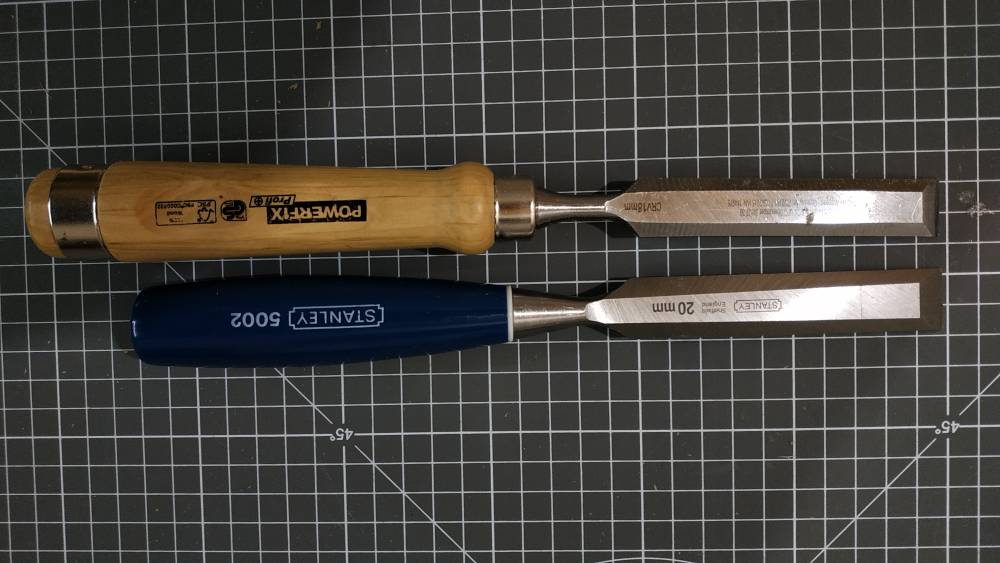

Rather than spend the big money straight away, I decided to see what a small step up in money would bring.

So, £7 for one 'new' 20mm Stanley 5002.

That's still about the price as all 4 of the Lidl chisels, and the Stanley has a plastic handle. It is marvel (depending on your point of view) of the global economy and manufacturing processes that you get a chisel with a sharp edge in half decent steel with a wooden handle from wood grown far from the country of manufacture and then your local super market sell it for less than 2 quid a chisel.

Anyway, the Stanley arrived in a sealed plastic case and was new. But, given the old Stanley logo, older looking photos and an absence of any web addresses, I am thinking this dates back to the mid to late nineties.

Comparing to a Lidl chisel, it seems like a bit more of a refined thing.

Mill marks are much lighter on the Stanley, and best of all the bevel edges are much, much shallower than the Lidl, which makes for a better dovetail maybe.

The handle on the Stanley is ok for being plastic. It has a nice shape, but the wood feel of the Hornbeam is nicer and the flared end is actually fairly practical.

I gave the back a flatten with the diamond stones, but it was actually pretty flat. Much flatter than the Lidl one out of the box that had a hollow in the middle.

After honing it was possible to get an end grain shaving in pine.

So, I might actually get a few more and use these for a while before spending big on some Ashley Isles or Japanese chisels.