smiler6303":mewim308 said:

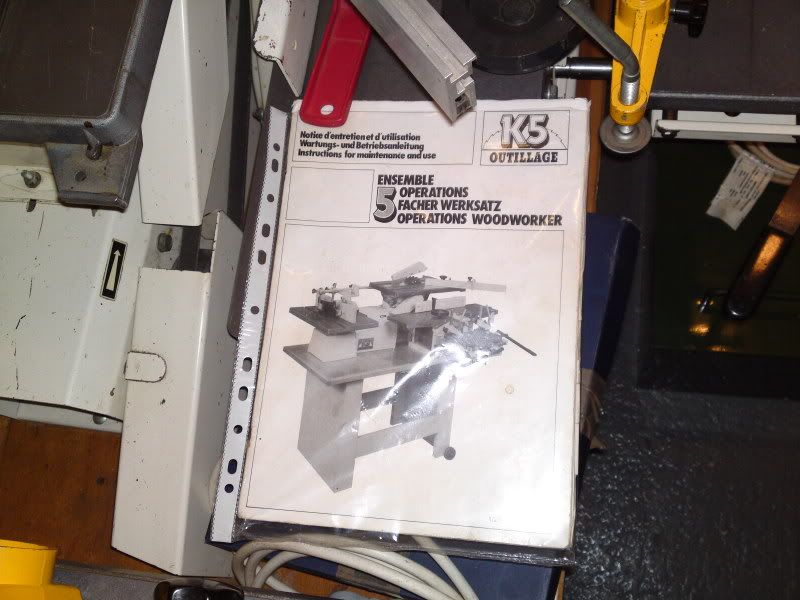

Hi Folks, I need your help ! I've just been offered a K5 machine, (sight unseen as yet), but I know nothing about them. Were they a good machine? what should I look out for? what sort of price range?

Any help would be much appreciated,

smiler

Hi

I bought one of these in 1987 just before they changed to a Bestcombi.

It's an excellent little machine as long as you remember it was aimed squarely at the home user.

All you need to check really are the usual bearings and motor. Look carefully at the condition in general and tables especially which will soon tell you how hard a life it's had.

Despite owning independant full size machines, I've kept the K5 and still use it regularly if I need something dome quickly, (my machine shop isn't set up yet and very easy just to pull out the K5).

Check what the machine has with it.

Is it 5 function? ie slot morticer included.

An extension saw table is useful

What tooling is included

All guarding to moulder and fence for saw etc

remember that apart from belts, you won't easily get spares but it's a simple set of independant machines linked to 1 motor so easily repaired.

Note limitation in tooling size and especially the 20mm spindle (I bushed a cutter block down from 30mm though).

specs:

Gen dimentions - 1015 x 555 x 620mm - weight 65kg

Motor - 1100wt (1 hp)

Saw - rise & fall (45d) - blade 200mm - depth of cut 60mm

Planer /thick - w = 149 x d = 100mm 2 knives HSS

Sp Moulder - Spindle 20mm (30 x 3mm slot)

Tool max h = 80mm dia = 100mm spd 5700rpm

slot morticer - Mortice len = 110 d = 90 height adjust = 50mm

I've got all the original docs including assembly, catalogues, accessories and price lists (out of date) as well as a couple of test / reveiw articles from that era so if you need info just pm me.

Hope that helps

I