Hi,

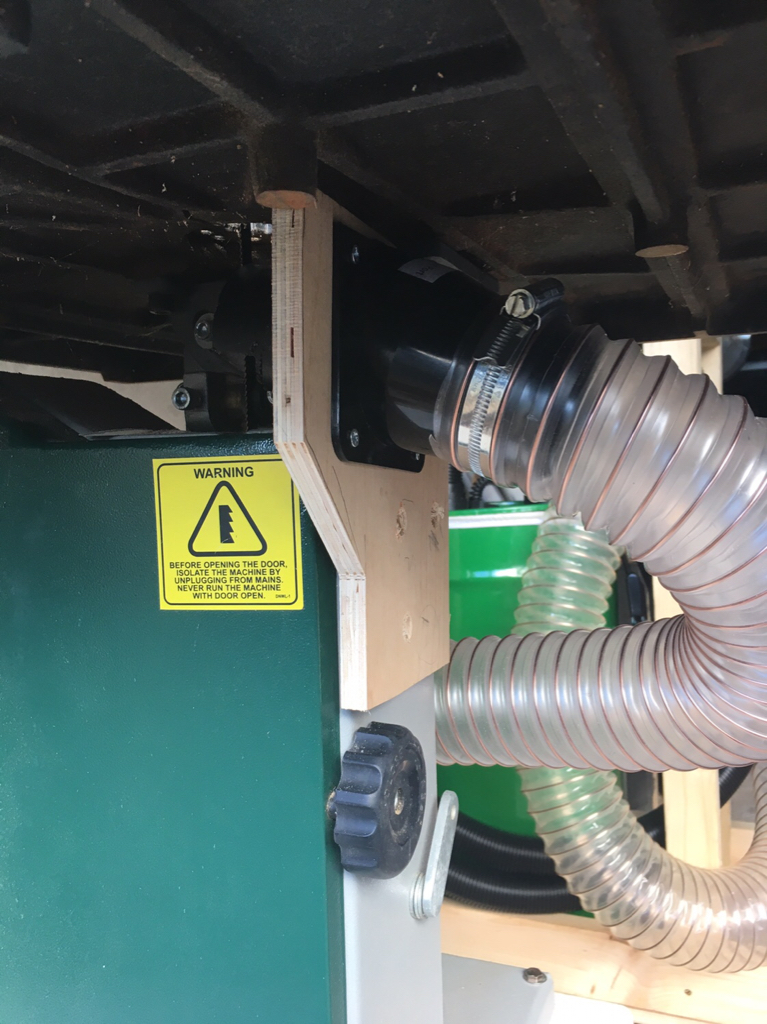

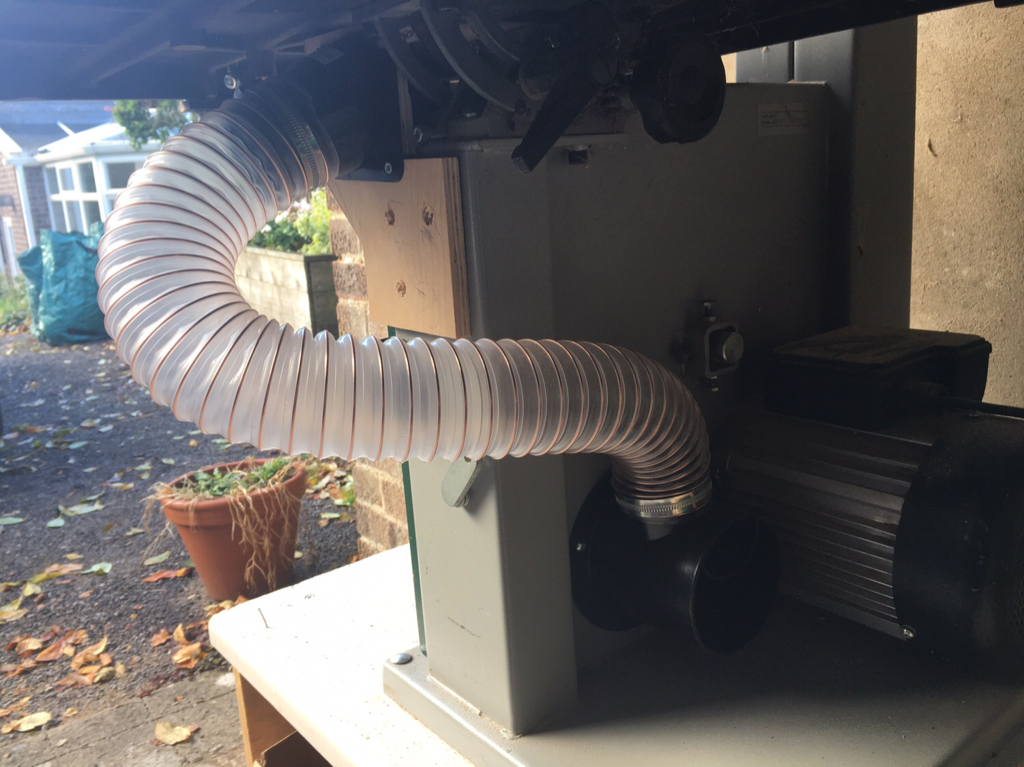

Has anyone modified their bandsaw to include under the table dust extraction ?

I’ve got a record 350 and have bought an Axminster adapter that gives me a 63mm output from the 4 inch port at the base, I’m just looking for inspiration on how to run / attach a pipe to end up just under the table by the blade

Any photos or ideas would be greatly appreciated !

Paul

Sent from my iPhone using Tapatalk Pro

Has anyone modified their bandsaw to include under the table dust extraction ?

I’ve got a record 350 and have bought an Axminster adapter that gives me a 63mm output from the 4 inch port at the base, I’m just looking for inspiration on how to run / attach a pipe to end up just under the table by the blade

Any photos or ideas would be greatly appreciated !

Paul

Sent from my iPhone using Tapatalk Pro