Rhyolith":t4szlshi said:

Its for machining components, but that does not matter as I know ‘normal’ size micrometres and verniers (etc) are fine (been stealing others).

The engineers I know do indeed have mitutoyo stuff, their verniers cost £160 each! Which is why I don’t simply get those. Is there any reason they are so dominant?

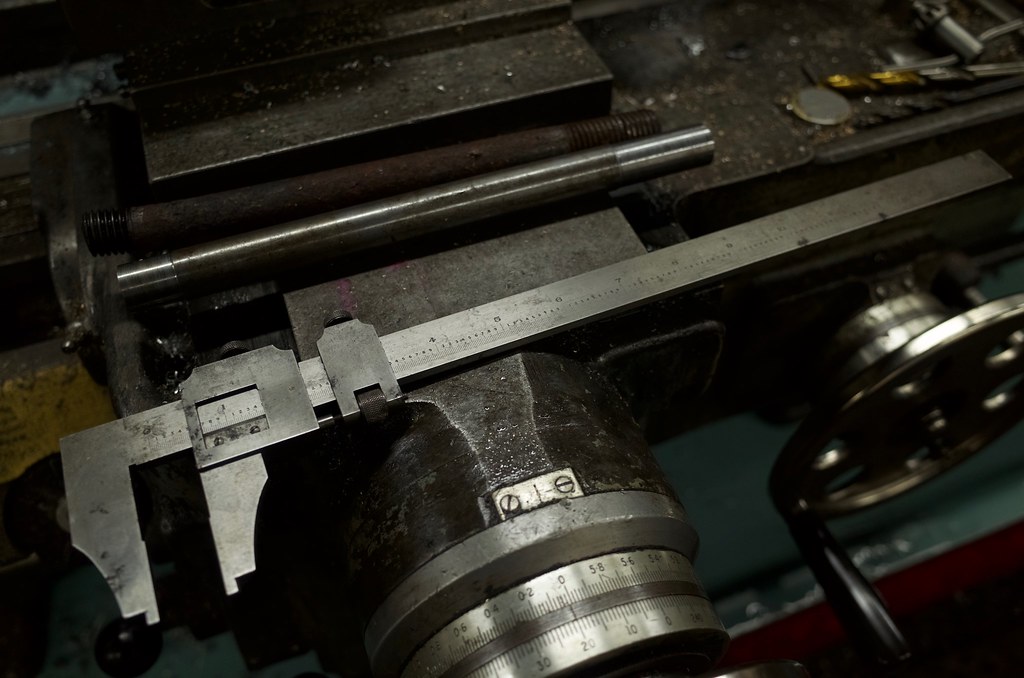

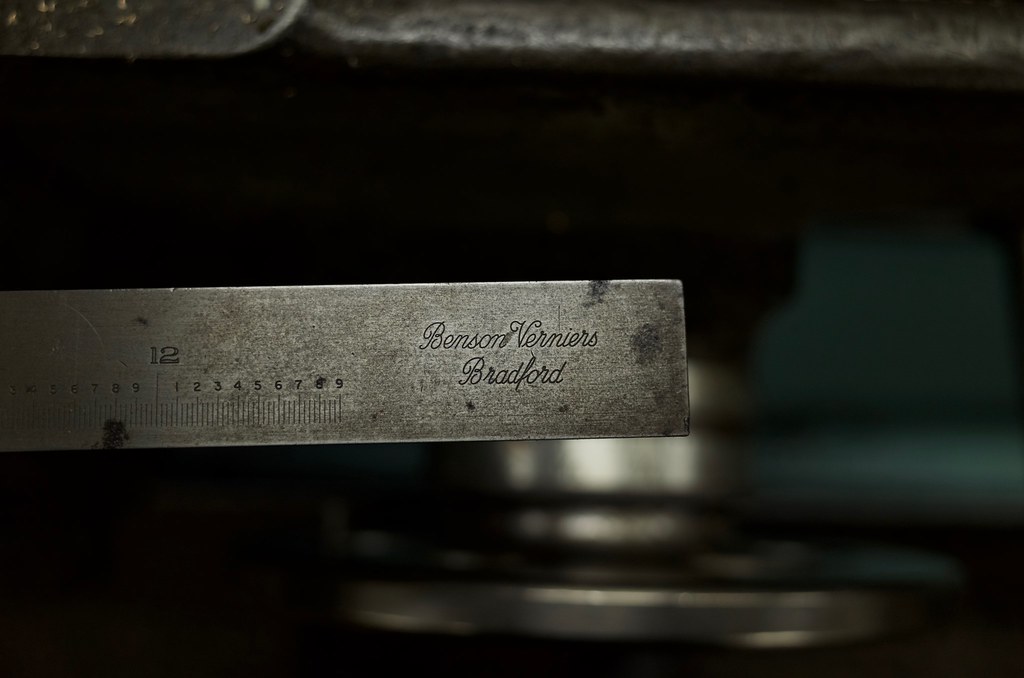

On a side note, anyone heard of ‘Bensons’ measuring tools? (old stuff)

Benson Verniers were a Bradford company, started 1946, and acquired by James Neill in 1972. As Neill's also owned Moore and Wright, I suspect they may have been buying out a competitor; I don't know when Benson Verniers ceased production, though. They made very good quality instruments, a couple of examples of which I've used. Their one disadvantage is that the scales, though nicely engraved, are not as easy to read as many decent quality modern ones, and especially so in less than perfect light or when measuring at odd angles - one up to the digitals, here, in my experience. Use with a magnifying glass and they're fine, though.

Second hand micrometers are something of a lucky dip, I'm afraid. If you come across ones with the manufacturer's grease and protection for the anvils and spindles still intact, snap 'em up, but pass on anything unboxed. Buy a new micrometer setting standard for each instrument (they're not that expensive, considering their precision nature), and check the instrument regularly. It's not as good as a 'proper' calibration check, but at least it'll let you know if any gross errors arise.

If you're just using the mic or vernier as a comparator (eg, want a bush 2 thou bigger than a hole for a press fit) then almost anything will do, but for work to specified absolute measurements you need to be a lot more choosy.

Useful instruments depend entirely on what you're making. Some vintage machinery will be quite happy with plus-or-minus a clog tip tolerances, but something like machine tool parts or internal combustion engine parts will demand split-thou accuracy, and far more expensive metrology gear. Hence the question earlier in the thread about what you're measuring.