Hi there,

new member but been lurking for a bit. I've had a brief search of "drill press" in the search bar to see if this has come up before. Couldn't see it but might have missed it.

I'm doing up my (small) one car garage that doubles as family storage area. On one side I will have my woodworking equipment and the other my mechanical stuff (fixing motorbike mainly but also occasional metalwork)

I need to know this now, as I'm acquiring all my equipment to model the space around, and most of that is sorted in my mind except for this conundrum: do I need (want) two pillar drills or just the one? I don't really want to settle into the space and after 6 months realise I have made the wrong choice. At the moment I think two pillar drills would mean forgoing a dedicated bench sander arrangement, and just taking a belt sander out and mounting it to my bench when needed. It's possible I've overlooked an efficiency and could have both pillar drills and a bench sander but that solution is apparent as yet.

Why do I think I need (want) to drill presses?

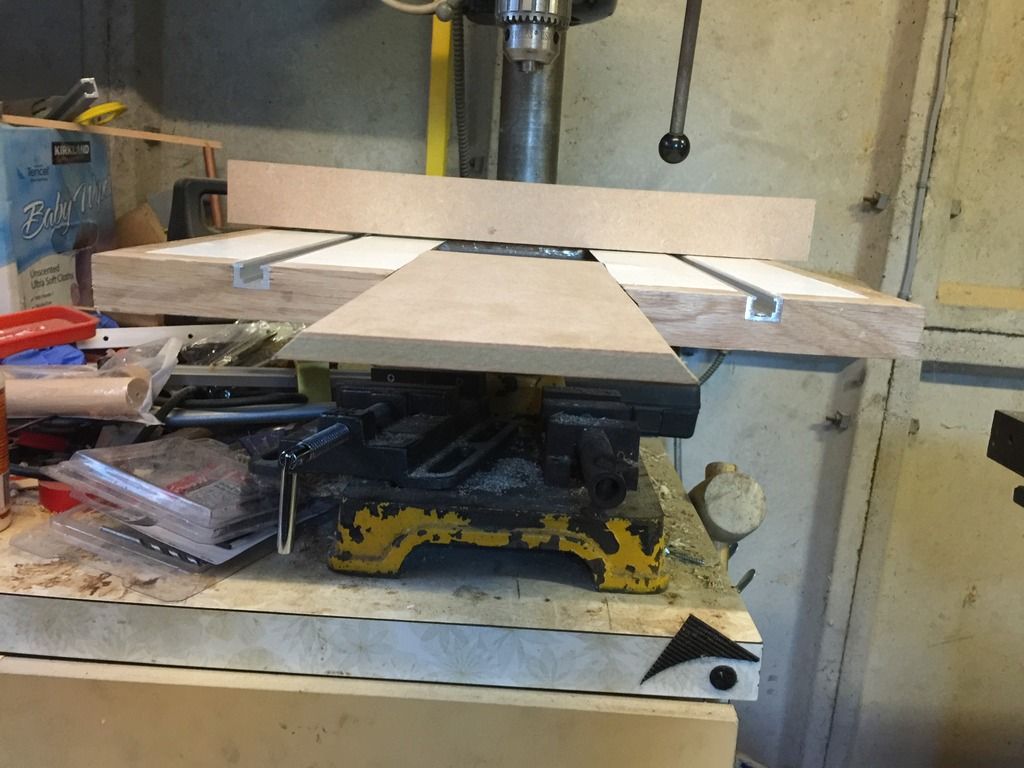

For woodwork I'd want a dedicated wooden drill press table on the Fobco Star I've just acquired

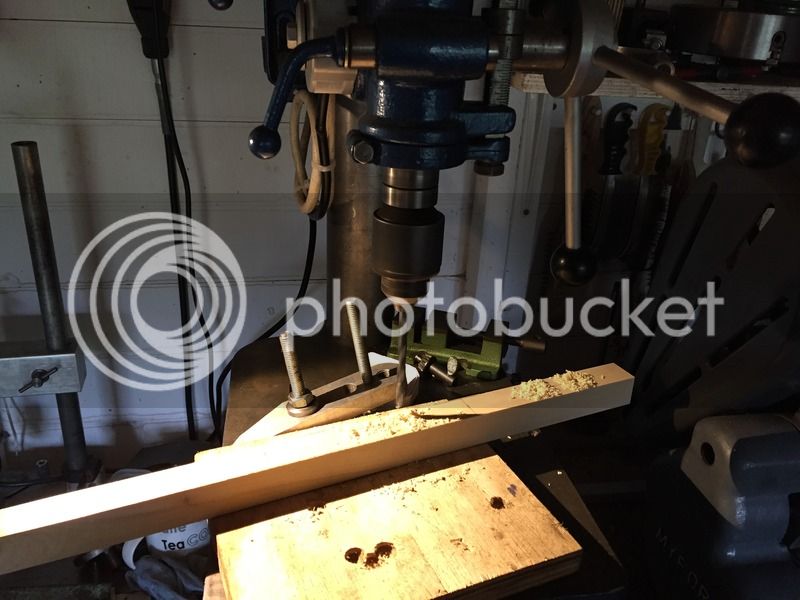

For metal work I think I'd want a vice mounted to the drill press table. I've not acquired this one yet as I'm hesitant.

Money isn't the deciding factor here since, as far as I'm concerned, all of the equipment I'm buying is only going to appreciate

new member but been lurking for a bit. I've had a brief search of "drill press" in the search bar to see if this has come up before. Couldn't see it but might have missed it.

I'm doing up my (small) one car garage that doubles as family storage area. On one side I will have my woodworking equipment and the other my mechanical stuff (fixing motorbike mainly but also occasional metalwork)

I need to know this now, as I'm acquiring all my equipment to model the space around, and most of that is sorted in my mind except for this conundrum: do I need (want) two pillar drills or just the one? I don't really want to settle into the space and after 6 months realise I have made the wrong choice. At the moment I think two pillar drills would mean forgoing a dedicated bench sander arrangement, and just taking a belt sander out and mounting it to my bench when needed. It's possible I've overlooked an efficiency and could have both pillar drills and a bench sander but that solution is apparent as yet.

Why do I think I need (want) to drill presses?

For woodwork I'd want a dedicated wooden drill press table on the Fobco Star I've just acquired

For metal work I think I'd want a vice mounted to the drill press table. I've not acquired this one yet as I'm hesitant.

Money isn't the deciding factor here since, as far as I'm concerned, all of the equipment I'm buying is only going to appreciate