wcndave

Established Member

Back in the old days, early 90's, I was fairly decent at soldering.

More recently, I had an old 40w iron with only one tip, and was struggling to do some finer work, and to even for example tin wires with it, as the solder beaded on the top, and was impossible to tin.

I got a 75w soldering station: http://www.expondo.co.uk/stamos-solderi ... apter-6100

However i have the same troubles. Even with 490 deg c, the iron cannot be tinned. It just beads up all over it. further down the top, it's fine.

Trying to solder a small joint, the solder would not melt against the wire before it became too hot to hold. Trying to solder into a PCB board, even with just a few seconds, it was hot enough for another component fell out, however the solder had not melted. It seems that the non-tinned tip is the problem, however try as I might, I cannot tin the tip of the iron.

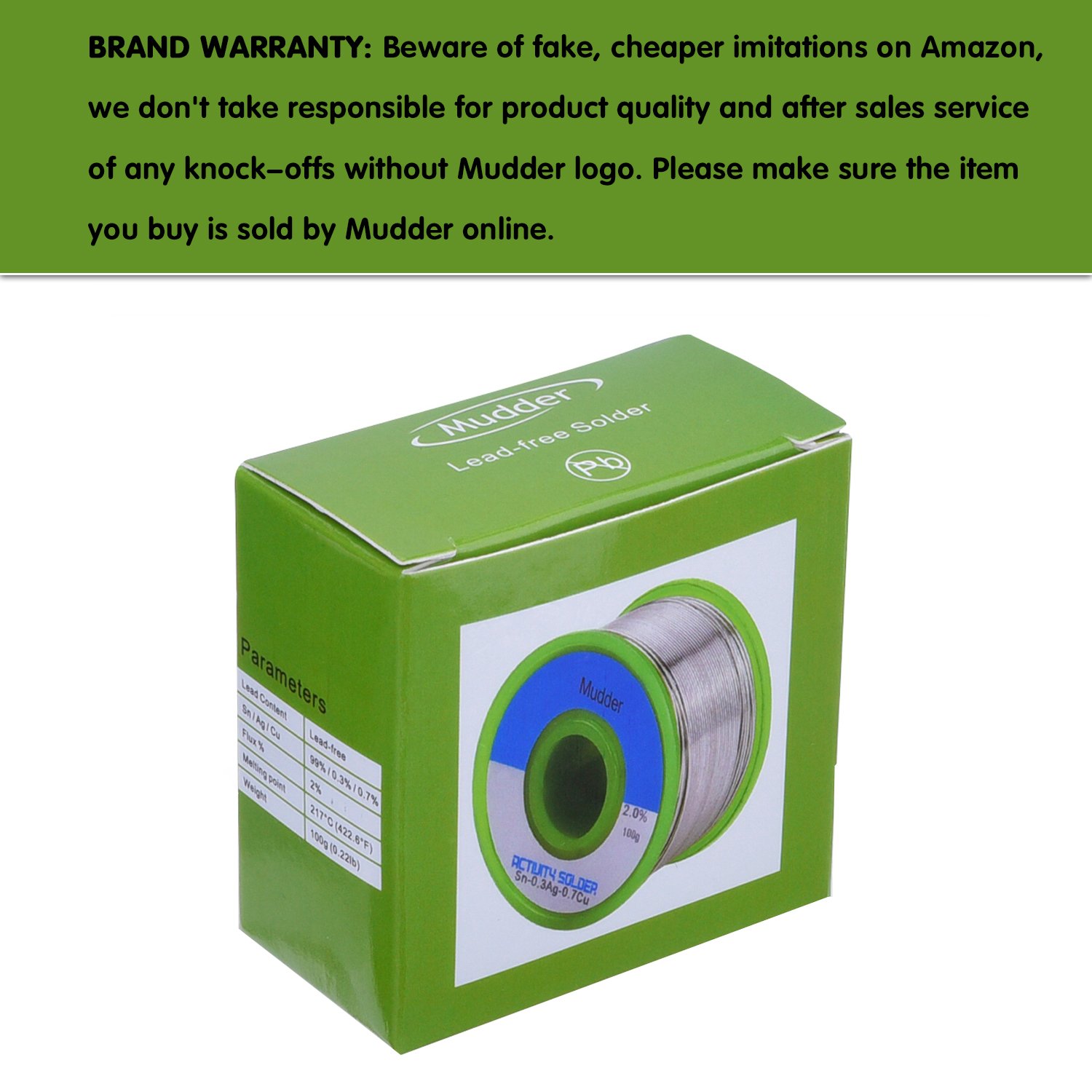

Does this more recent non-lead solder require some other technique?

Hoping for help!

Dave

More recently, I had an old 40w iron with only one tip, and was struggling to do some finer work, and to even for example tin wires with it, as the solder beaded on the top, and was impossible to tin.

I got a 75w soldering station: http://www.expondo.co.uk/stamos-solderi ... apter-6100

However i have the same troubles. Even with 490 deg c, the iron cannot be tinned. It just beads up all over it. further down the top, it's fine.

Trying to solder a small joint, the solder would not melt against the wire before it became too hot to hold. Trying to solder into a PCB board, even with just a few seconds, it was hot enough for another component fell out, however the solder had not melted. It seems that the non-tinned tip is the problem, however try as I might, I cannot tin the tip of the iron.

Does this more recent non-lead solder require some other technique?

Hoping for help!

Dave