giantbeat":3t2epcf6 said:im a bit late to this thread, been an interesting read... i have done a far bit of sound treatment in my life, i have built 3 recording /rehersal studios in the past 10 years.

what i was going to say when i saw your first attempt is what Bob was saying re the lining, make it loose, make it completely random... essentially with sound treatment you have 3 tools to fight how the sound travels....

mass (thick dense walls to block & shield)

absorption (soft layers to muffle)

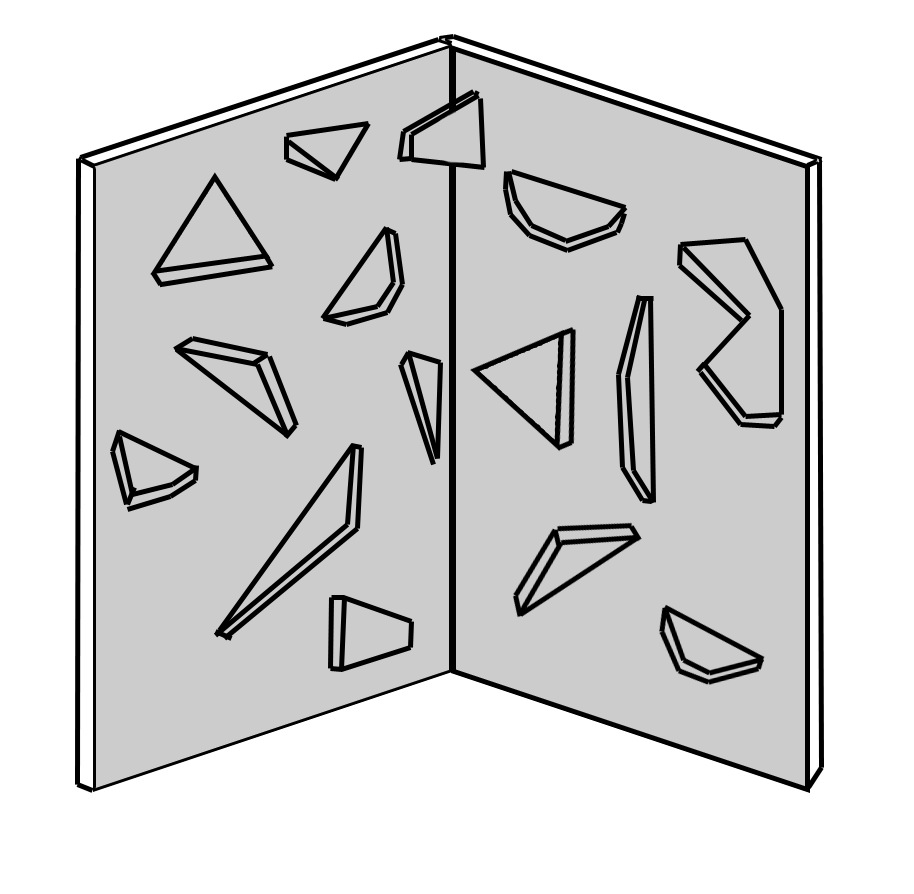

random surface treatment via baffles (odd shapes to break up the waves)

the first attempt was certainly missing the latter, so randomizing the inside with loose material would as Bob said would be the way to go.

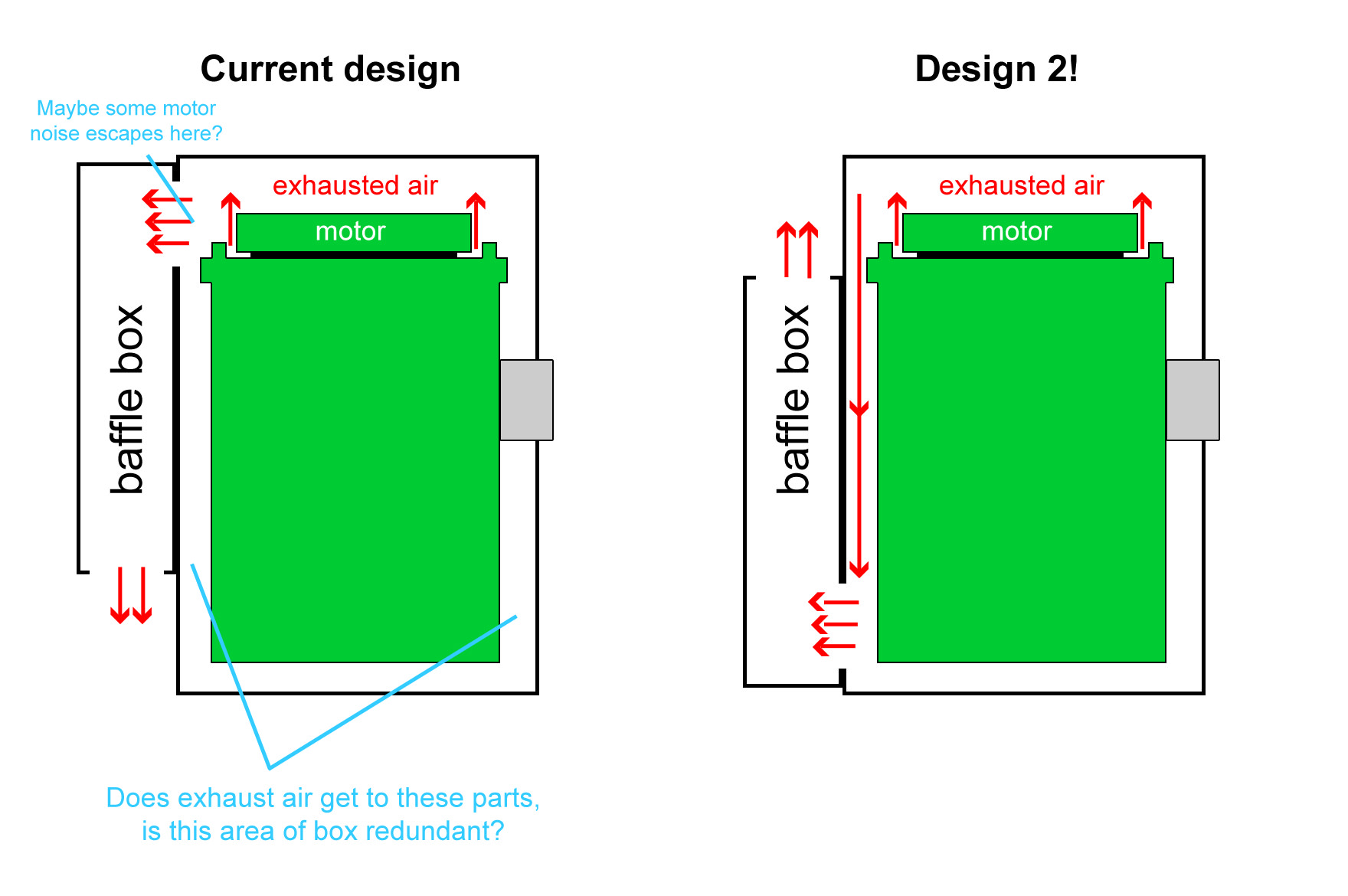

im slightly confused as to how you have made it worse with your latest attempt, if anything i would have expected it to be about the same... however you do seem to be going for consistency on your work & that goes against you in sound treatment, the air & sound will just roll over it.

i would have placed my baffles at varying spacing (keeping in mind not to restrict airflow but allow areas that let it pool before moving on & i would have also suck off cuts & random shapes to them before i then lined them with a material & foam, but the messier & more inconstant the better.

this is exactly how we build ventilation ducts for studios where we needed reasonable sound proofing but still want fresh air.

Thanks for your post!

I'm due to pick these up tonight...

I was thinking I could cut them down and fit them inside cabinet. Do you think these would work or would I be better off getting that spikey acoustic foam type stuff?