toolsntat

Yep, I collect tools and tat

Can you not lift it out and bandsaw off the riser, reshape the step to suit then reapply the riser?

toolsntat":2rw1rk13 said:Can you not lift it out and bandsaw off the riser, reshape the step to suit then reapply the riser?

Trainee neophyte":3cdrbiaw said:I've been keeping very quiet

But not if the structure won't support itRogerS":1tefxdwx said:.......

Design is all.

Nothing rustic about trad staircases, least of all Georgian. Here's one, albeit newly made. https://www.homify.co.uk/projects/45876 ... ase-surreyNot Jacob's clunky old-fashioned rustic style.

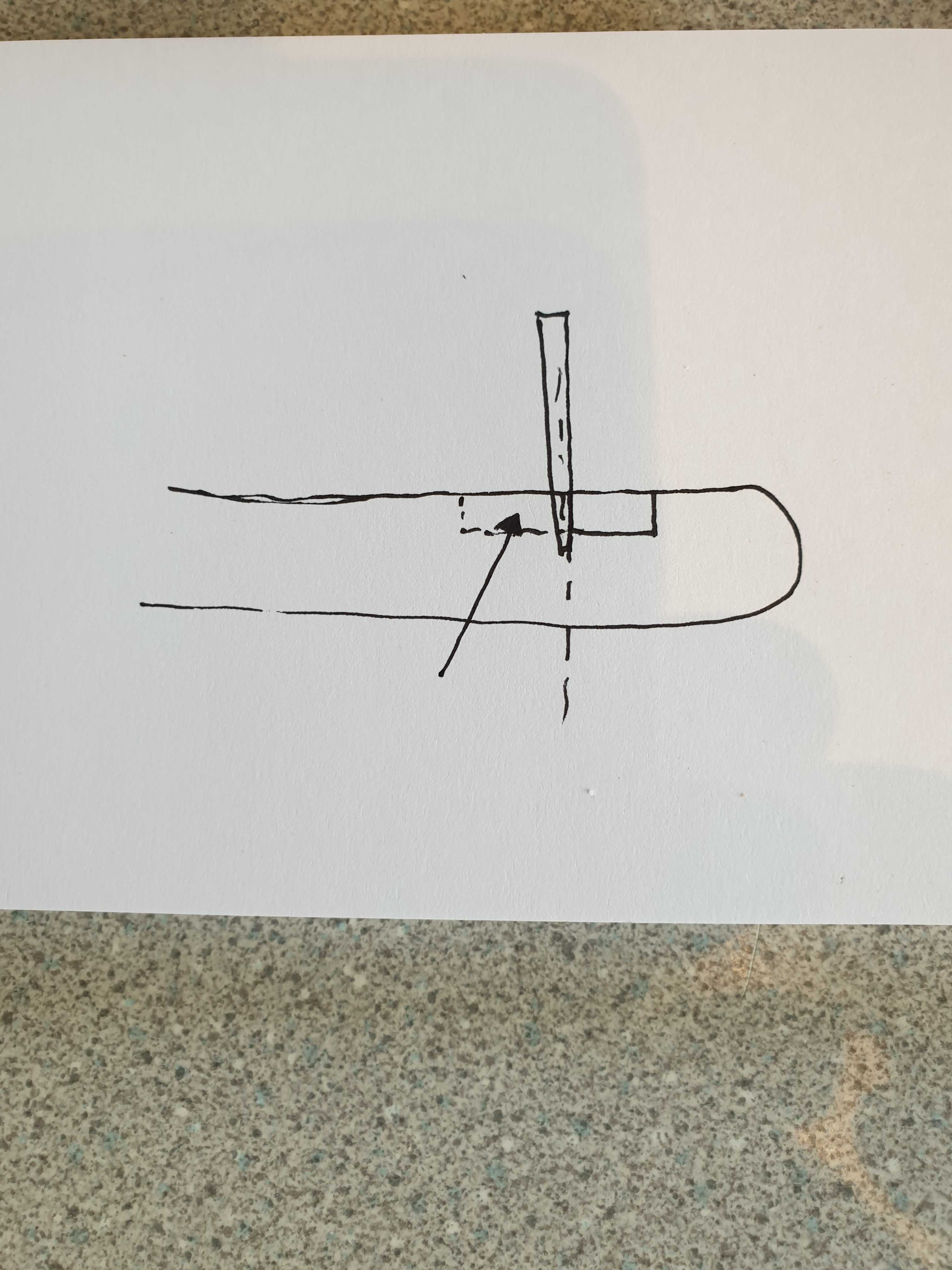

ColeyS1":1hxxgakf said:Would a groove not make your life alot easier in terms of gluing up and getting a nice tight joint? The nosing would be wider aswell.

Sent from my SM-G960F using Tapatalk

ColeyS1":q8hw2sv4 said:The nosing would be the exact same size to look at,just have more support underneath. .....

Sent from my SM-G960F using Tapatalk

RogerS":37xxc2u6 said:Design is all. Not Jacob's clunky old-fashioned rustic style.

Not to mention the folding wedges to to pull it all tight!Trevanion":284nelr1 said:RogerS":284nelr1 said:Design is all. Not Jacob's clunky old-fashioned rustic style.

To be fair, Jacob's "clunky old-fashioned rustic style" has been how I've been doing bullnose/d-end risers for years. Before that, it was removing all the material instead of kerfs, cut a dovetail on each shoulder so it acted like a sliding dovetail, make a softwood block that had the correct radius and the dovetails at the ends of the radius so that they locked together,.....

Jacob":7cw88dvt said:.....

The reason why 'traditional' is worth looking at is that it is the distilled and combined wisdom of how to do difficult things, from generations of people struggling and succeeding in doing the stuff.

...

"Reinventing the wheel" in the case of your progressive futuristic stair case. Good job it wasn't a whole flight!RogerS":33a5rd1x said:Jacob":33a5rd1x said:.....

The reason why 'traditional' is worth looking at is that it is the distilled and combined wisdom of how to do difficult things, from generations of people struggling and succeeding in doing the stuff.

...

Yeah...right. Like people saying "Use Danish oil"

If you had your way, Jacob...we'd still be using logs to move stuff about and the wheel would never have been invented.

Jacob":3dsq0zpy said:Or reinvented in the case of your progressive futuristic stair case. Good job it wasn't a whole flight!RogerS":3dsq0zpy said:Jacob":3dsq0zpy said:.....

The reason why 'traditional' is worth looking at is that it is the distilled and combined wisdom of how to do difficult things, from generations of people struggling and succeeding in doing the stuff.

...

Yeah...right. Like people saying "Use Danish oil"

If you had your way, Jacob...we'd still be using logs to move stuff about and the wheel would never have been invented.

Oh is it finished? Well done.RogerS":1xgdnvjq said:Jacob":1xgdnvjq said:Reinvented the wheel "in the case of your progressive futuristic stair case. Good job it wasn't a whole flight!RogerS":1xgdnvjq said:.....

Yeah...right. Like people saying "Use Danish oil"

If you had your way, Jacob...we'd still be using logs to move stuff about and the wheel would never have been invented.

You've got the right word...progress !!

Enter your email address to join: