Tick stick it.

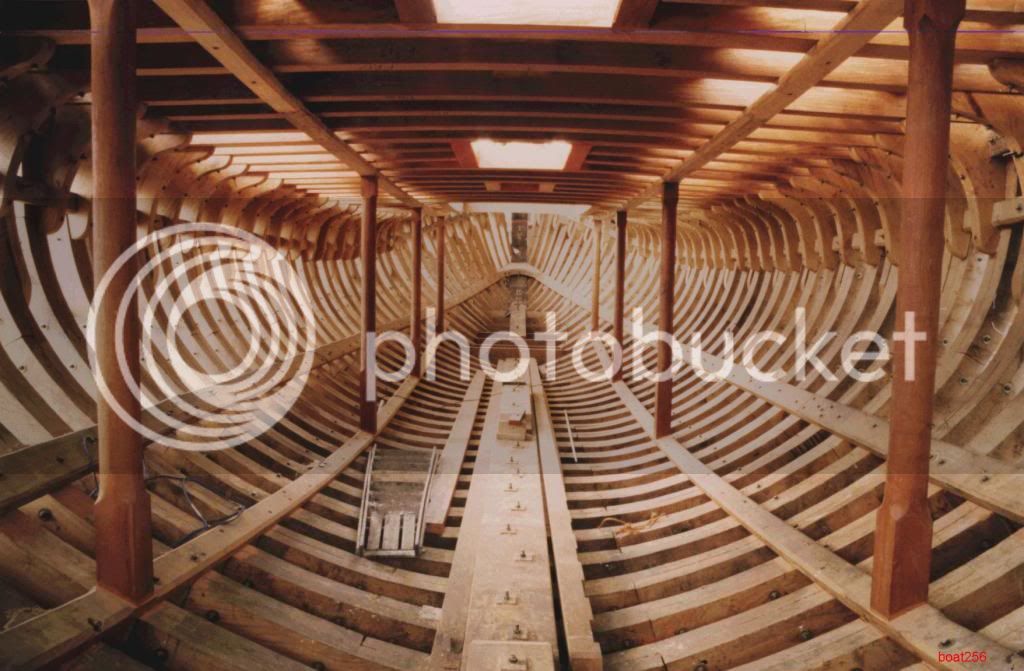

A technique used by boat builders for over 1000years.

In brief,

stand a board smaller than the opening, in it, in a fixed position(B&D workmate does well)

Take a length of stick with a pointed end, lay it against the board with the point end in bottom corner, mark a line against it as long as possible and at some point midway mark both board and stick with coinciding lines.

Continue at various positions around the opening, as many as practicable on curved edges, if needed make a second or third reference line on the stick but mark them accordingly.

Back in the shop layout sheet material to use as a full size template, on the floor if need be. Lay the site reference board on top and using the stick aligned with the reference marks layout each point of contact.

Join the dots. Just like the old comic books dot to dot. For curves panel pins and string help.

Cut out the shape, it will be as near as dammit the shape required.

On boats it can be too accurate in that it is too tight to get into place. :lol:

And yes! that is the brief description.