Wend

Established Member

Hi folks,

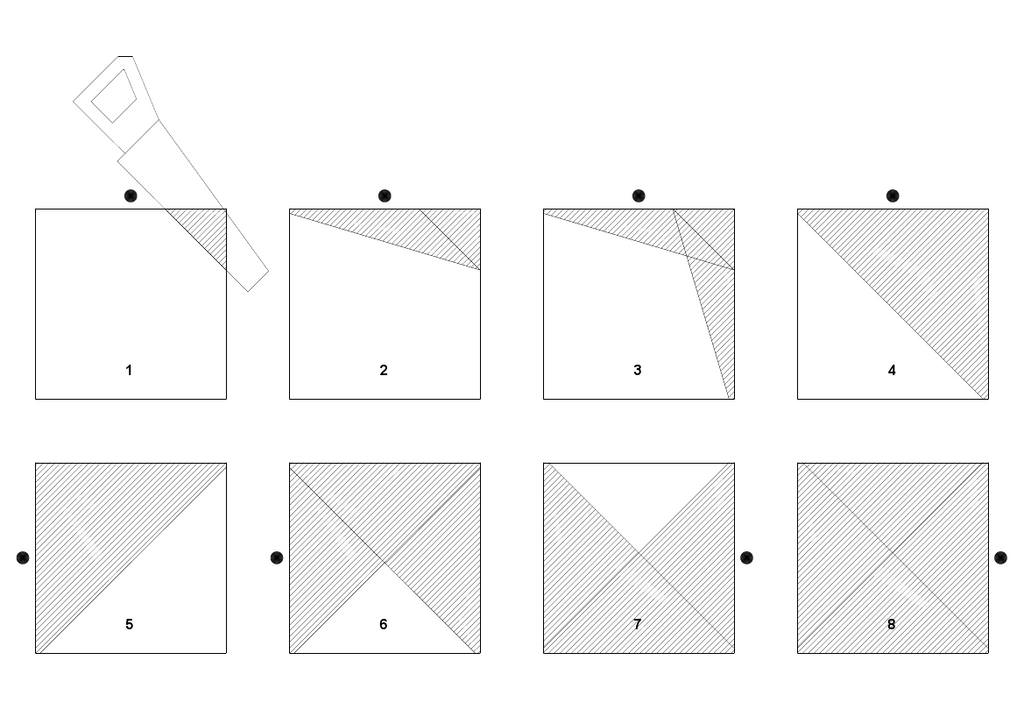

Today I tried cutting one of the legs for my bench square. I made a knife wall around all 4 sides (which happily joined up more or less dead on!), and used a chisel to remove a bit of wood leading up to it on the waste side. However, while one side (the top I think) ended up being cut pretty much where I wanted, the cut drifted away down the sides and was this completely out at the bottom, as shown by these photos (which were actually taken after a little end grain planing, but I don't think much had changed yet):

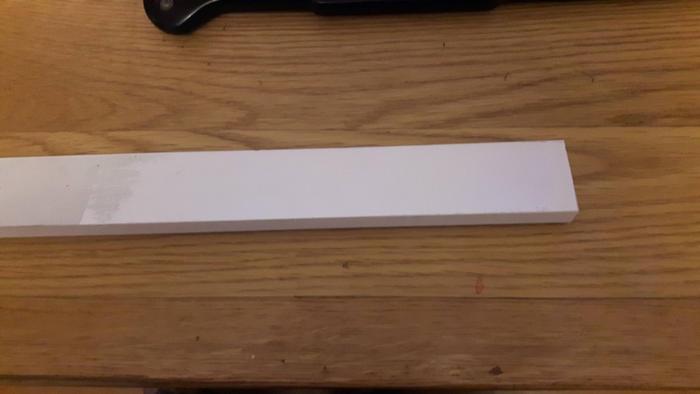

I thought that this wall would prevent tearout while planing the end grain, but apparently not!:

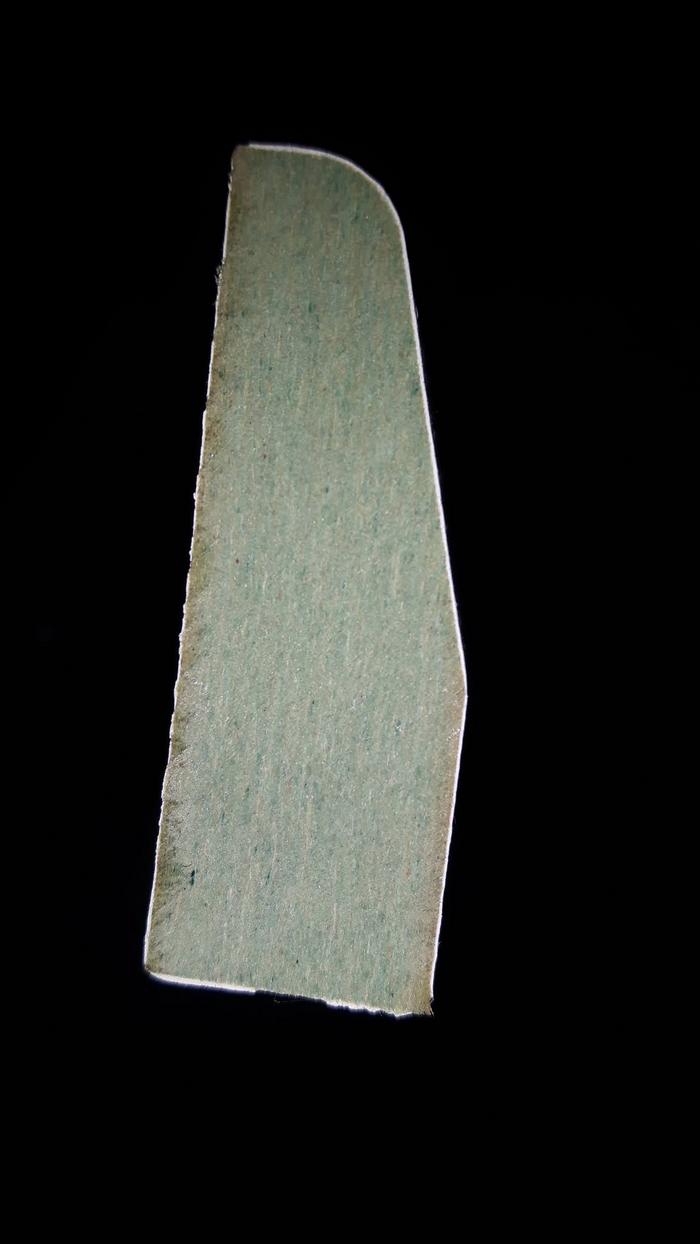

Looks like I'm off by about a millimeter:

I'm still finding end grain planing hard work - a lot harder than regular planing - so I'd like to minimise the amount I need to do; otherwise I might give in and let the disc sander do the hard work! As the leg is still a few cm too long, I think I'll try to cut it off again, past the torn-out bit, and see if I can get it squarer. But I'm wondering if a different tool would be easier for a beginner to cut squarely with.

I was using the (finer-toothed side) of a https://www.workshopheaven.com/gyokucho ... 180mm.html to do it. I also have a https://www.workshopheaven.com/gyokucho ... 180mm.html so, looking at the descriptions again, perhaps that would be a better choice?

But I wonder if a western saw would be easier? I chose the Japanese saws as I don't need to sharpen them when newly-bought (the bench project is already a side track, so I'd like to not get further sidetracked into learning to sharpen saws at this point), and I thought that the pull action would be easier for a beginner.

So, am I likely to be best off with the 291, 293, or do there exist western saws that will be easier to use out of the box?

Many thanks for any advice!

Today I tried cutting one of the legs for my bench square. I made a knife wall around all 4 sides (which happily joined up more or less dead on!), and used a chisel to remove a bit of wood leading up to it on the waste side. However, while one side (the top I think) ended up being cut pretty much where I wanted, the cut drifted away down the sides and was this completely out at the bottom, as shown by these photos (which were actually taken after a little end grain planing, but I don't think much had changed yet):

I thought that this wall would prevent tearout while planing the end grain, but apparently not!:

Looks like I'm off by about a millimeter:

I'm still finding end grain planing hard work - a lot harder than regular planing - so I'd like to minimise the amount I need to do; otherwise I might give in and let the disc sander do the hard work! As the leg is still a few cm too long, I think I'll try to cut it off again, past the torn-out bit, and see if I can get it squarer. But I'm wondering if a different tool would be easier for a beginner to cut squarely with.

I was using the (finer-toothed side) of a https://www.workshopheaven.com/gyokucho ... 180mm.html to do it. I also have a https://www.workshopheaven.com/gyokucho ... 180mm.html so, looking at the descriptions again, perhaps that would be a better choice?

But I wonder if a western saw would be easier? I chose the Japanese saws as I don't need to sharpen them when newly-bought (the bench project is already a side track, so I'd like to not get further sidetracked into learning to sharpen saws at this point), and I thought that the pull action would be easier for a beginner.

So, am I likely to be best off with the 291, 293, or do there exist western saws that will be easier to use out of the box?

Many thanks for any advice!