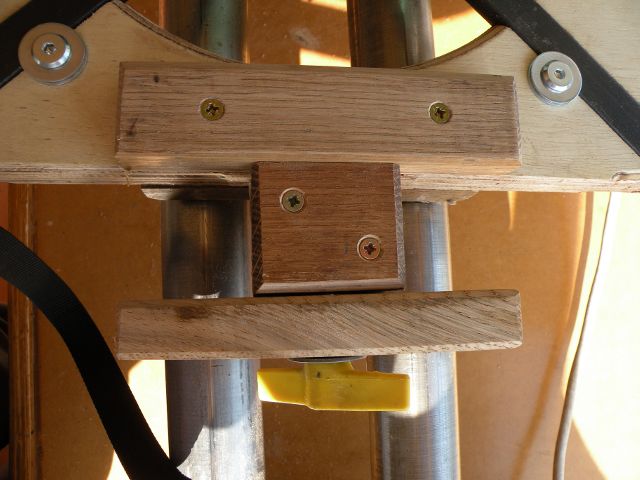

Tom, to make life easy for yourself just use the used inline skate wheels as suggested. They come with two bearings in each wheel, and the mounting bolts, nuts, spacers, and washers from the skate frame. All you have to do is supply the frame and arms.

If you think the wheels are a bit too big, remove the bearings, make a wooden plug for each side with a large bolt and nut through the middle, Put this in your chuck and gently turn the wheels down to the size you want. Having them the same size isn't critical as they adjust separately. Just leave enough meat to support the bearings.