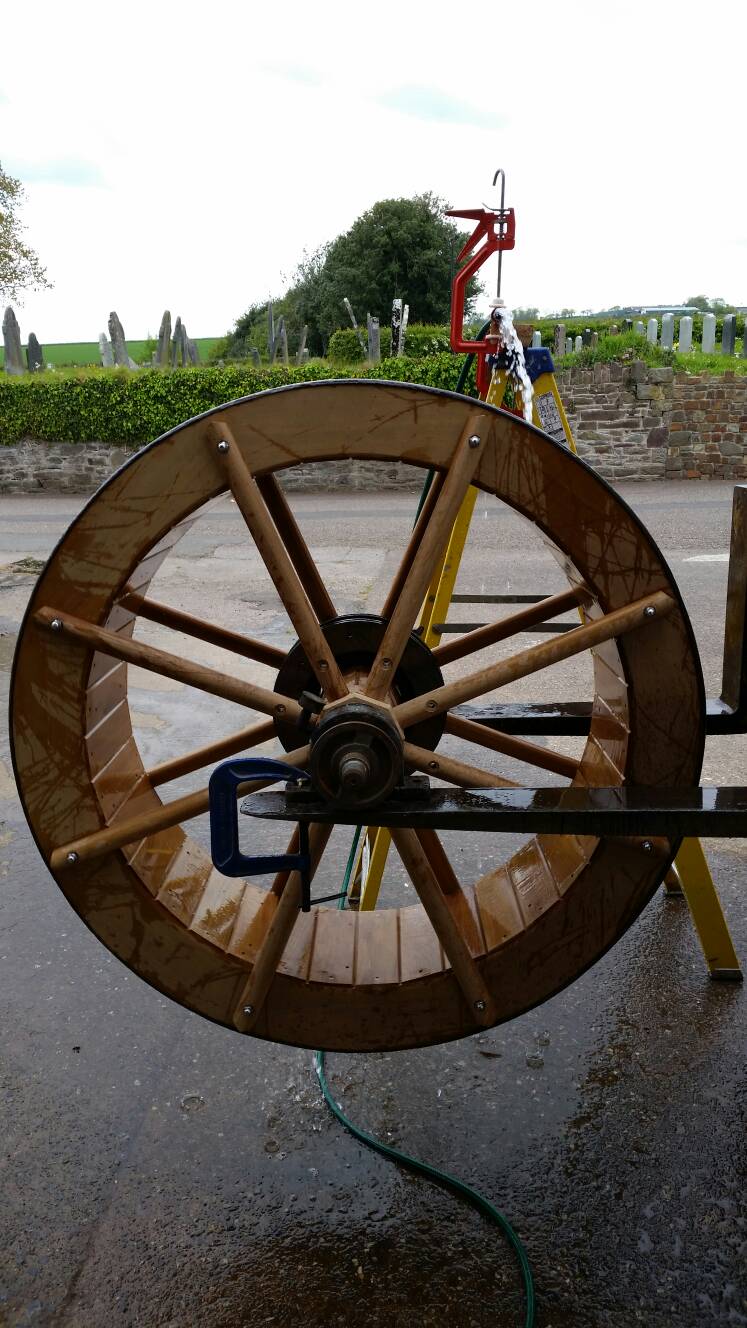

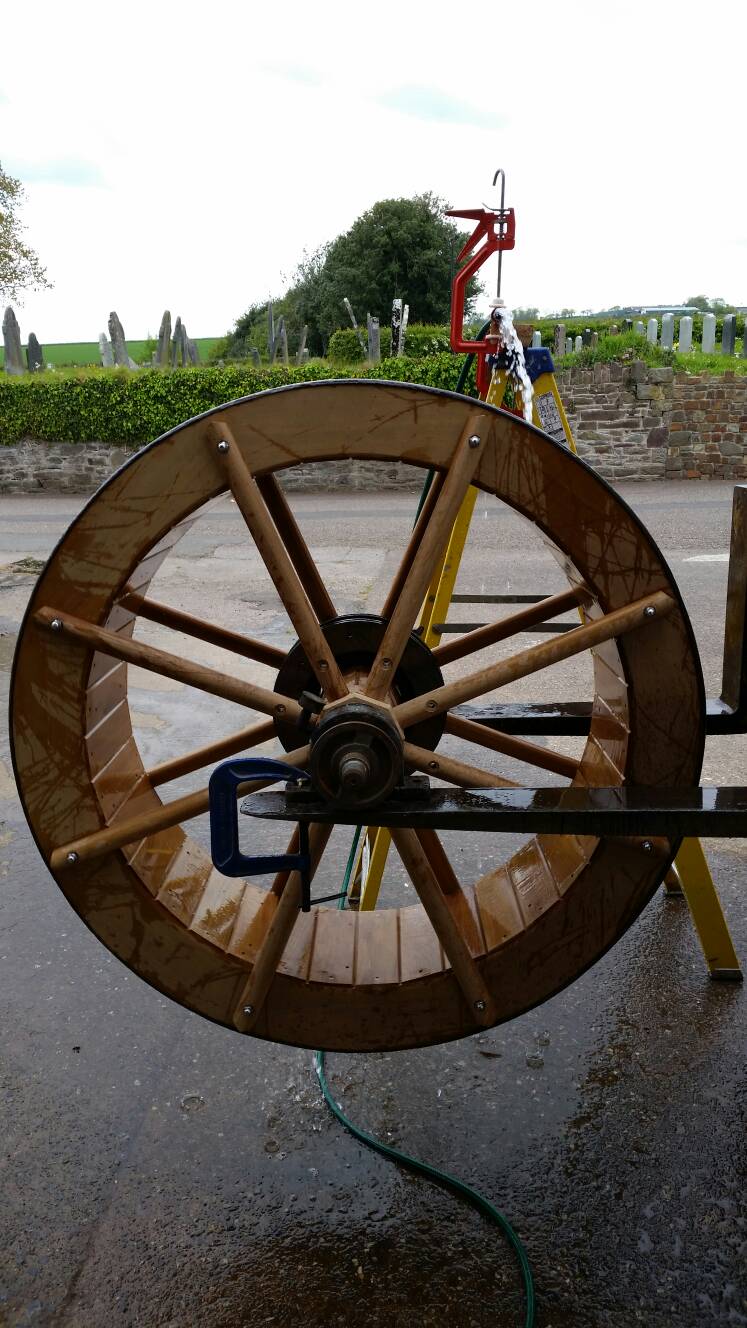

I was looking forward to fitting the spokes.

I screwed a spoke onto the hub and dropped the brake discs on over.

The threaded bar was already in place so I hooked on the spoke and hub

The first was the worse, everything after that was much easier

At this point everything was still loose. It was only the threaded bar stopping the side from falling off.

I worked my way around the wheel tightening each nut- it was fair creaking and snacking as I began torqueing em up :lol:

Seemed all was going well, until-

I couldnt get access to the end bolts that needed to bolt on th shaft- balls. I undone the brake discs and moved them out the way near the middle of the hub.

I wound the outer bolts so they were all in the same position, then inserted the shaft through the hole. 90 degree turns equally on the ratchet and the shaft was secure.

The pulley that originally ran the saw fits onto the shaft where the saw blade was. Mike could we maybe use this to get motion ?

Pushing the wheel over to the forklift, I noticed the bearings were staying level

That did make me feel slightly more confident that the bearings may be o.k.

I left the break discs in the middle of the hub so I could still get access to the bolts that clamped against the shaft. Spinning the wheel with my hand, it looked pretty good. I tightened up all the rest, then got a hose pipe to see if the thing would turn.

https://drive.google.com/file/d/0B4fhKh ... p=drivesdk

I was really pleased that it turned with only a hose pipe. I had been looking at pumps that moved 15000+ litres an hour ! The hose pipe filled a 25 litre drum in a tad over 2 minutes 45seconds.

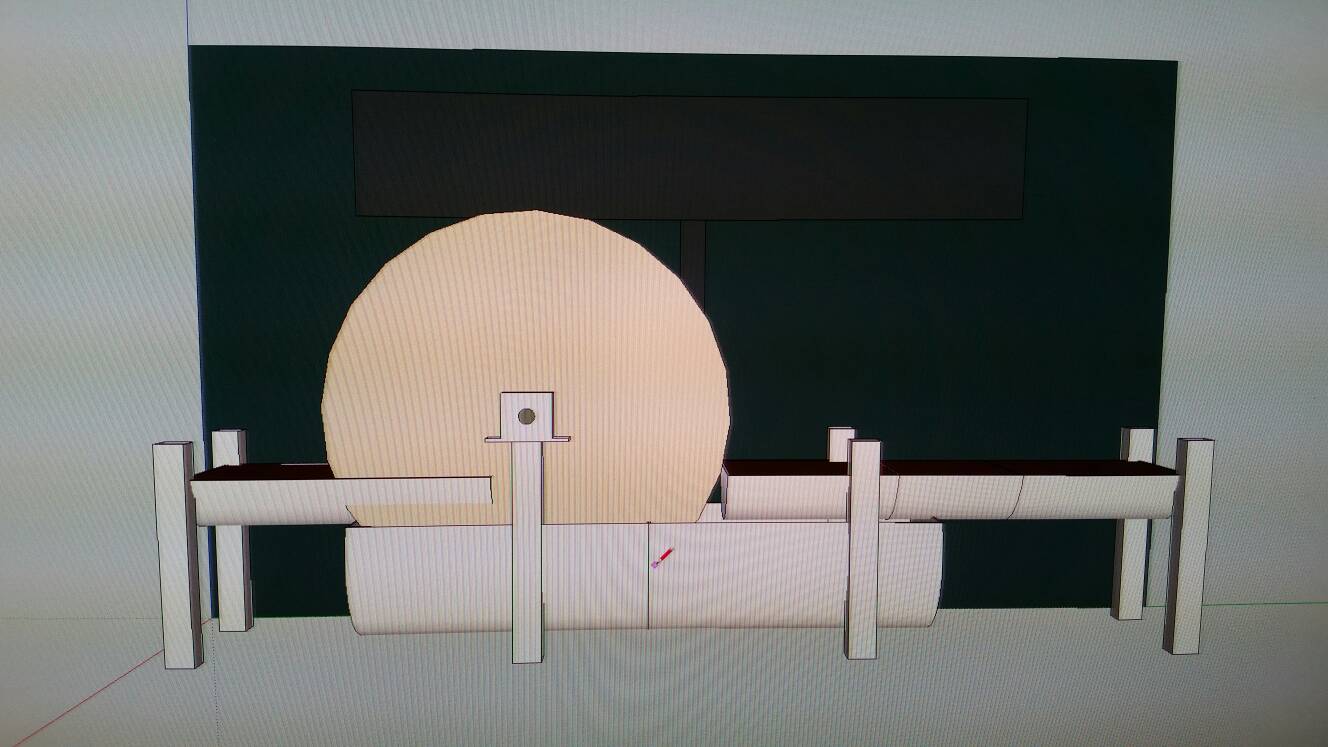

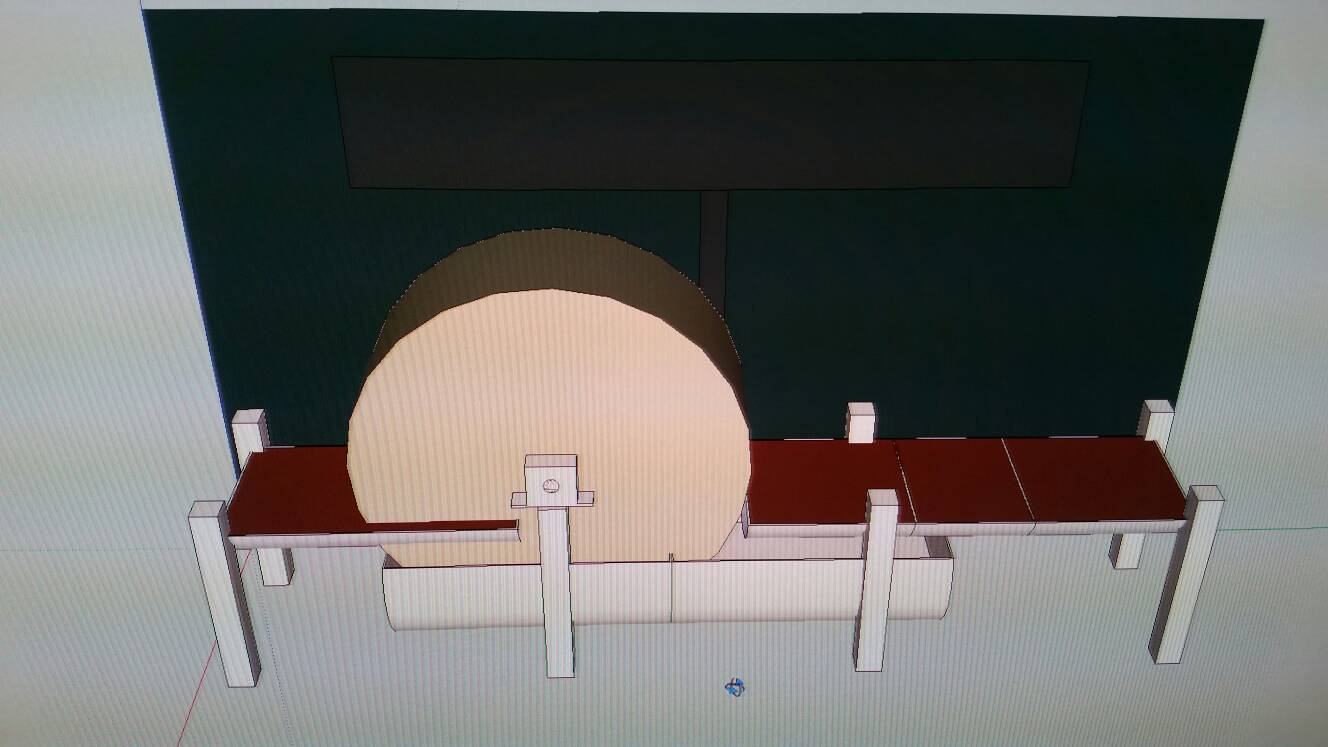

I glad it can finally be wheeled around the workshop in one piece- I'm getting cold feet about using the tablesaw to mount it on now though....

Cheers

Coley

I screwed a spoke onto the hub and dropped the brake discs on over.

The threaded bar was already in place so I hooked on the spoke and hub

The first was the worse, everything after that was much easier

At this point everything was still loose. It was only the threaded bar stopping the side from falling off.

I worked my way around the wheel tightening each nut- it was fair creaking and snacking as I began torqueing em up :lol:

Seemed all was going well, until-

I couldnt get access to the end bolts that needed to bolt on th shaft- balls. I undone the brake discs and moved them out the way near the middle of the hub.

I wound the outer bolts so they were all in the same position, then inserted the shaft through the hole. 90 degree turns equally on the ratchet and the shaft was secure.

The pulley that originally ran the saw fits onto the shaft where the saw blade was. Mike could we maybe use this to get motion ?

Pushing the wheel over to the forklift, I noticed the bearings were staying level

That did make me feel slightly more confident that the bearings may be o.k.

I left the break discs in the middle of the hub so I could still get access to the bolts that clamped against the shaft. Spinning the wheel with my hand, it looked pretty good. I tightened up all the rest, then got a hose pipe to see if the thing would turn.

https://drive.google.com/file/d/0B4fhKh ... p=drivesdk

I was really pleased that it turned with only a hose pipe. I had been looking at pumps that moved 15000+ litres an hour ! The hose pipe filled a 25 litre drum in a tad over 2 minutes 45seconds.

I glad it can finally be wheeled around the workshop in one piece- I'm getting cold feet about using the tablesaw to mount it on now though....

Cheers

Coley