DBT85

Established Member

Thanks Mike.MikeG.":3hnlp8ea said:DBT85":3hnlp8ea said:.......Out of interest. Is a rafter tie needed for every pair or is it every other or every third or something?......

The roof has to be looked at as a whole. The stiffness of the wall plate and the strength of the ridge beam come into the equation, as do the existence or otherwise of purlins. The point it, you can generally have widely spaced ties, or no ties at all, if that's what is designed in from the start. My suggestion is to say what you would ideally end up with and let's work backwards from there.

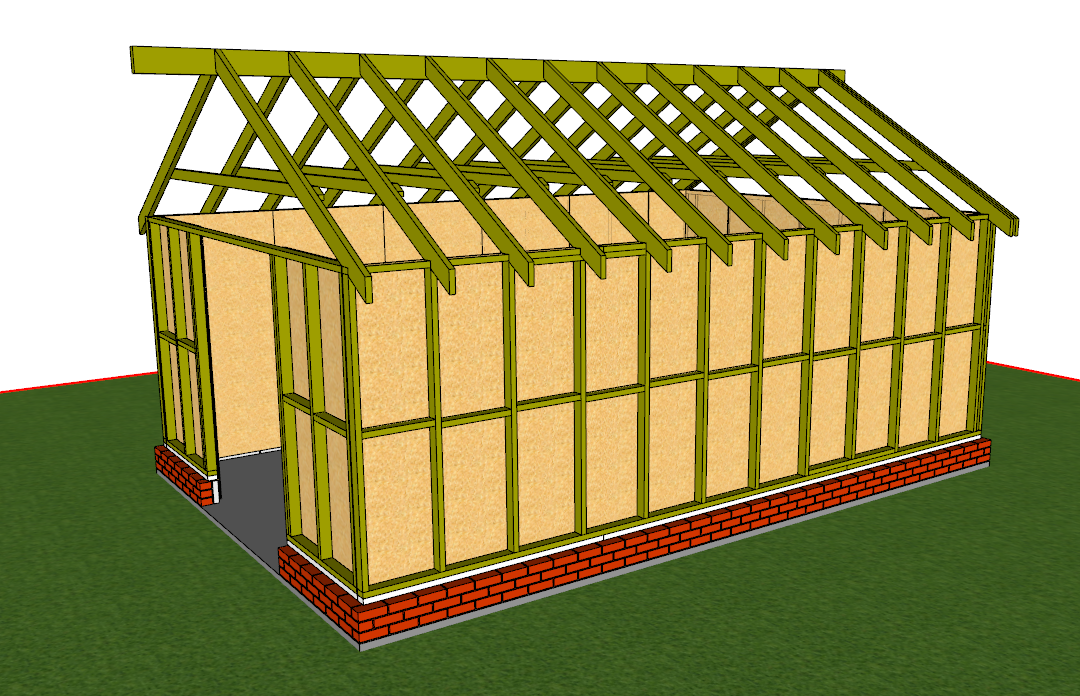

I'd really like as much open space above me as possible while also obviously having some storage up there. Right now the plan has a 195x67mm beam in there, rafters every 600/610mm to match the walls and I've also put ties in on every rafter for the sake of it with the top of each being 1/3 of the vertical height from the top of the top place to the top of the ridge. From the inner edges of each top plate the span is 6639mm. Again, I'm literally making things up so everything can and likely will change as required.

The roof will be Onduline or a metal tile like Decra or Metrotile.

Can you offer any suggestion on what mix the concrete should be. Gen 3, C25 or 30, RC30 etc? Since I'd be putting mesh in shuld I be thinking about an RC mix or not bother for this installation?