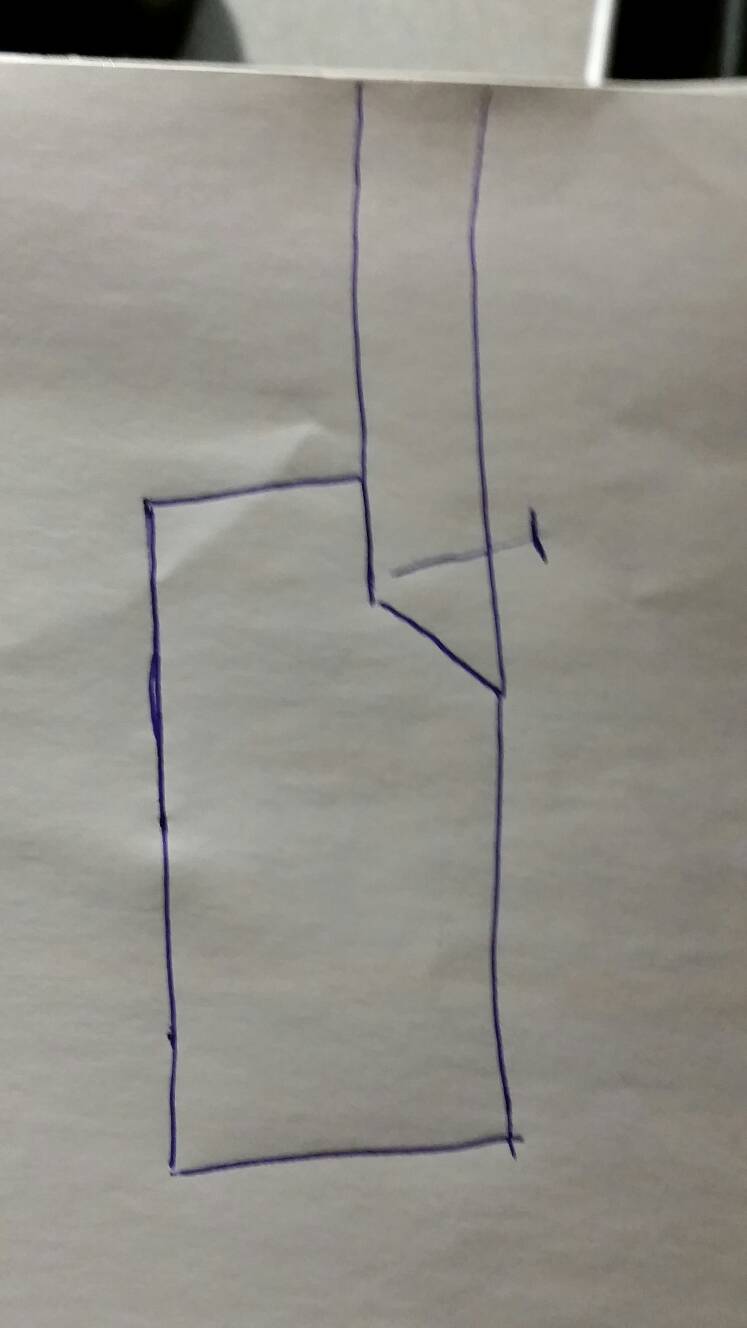

So I'm looking to make a side hinged garage door. Due to the slope of my drive, it is going to be tight, but if I build a slightly thicker frame this should be possible.

Mum has to sign off on this one! The design she likes is found here: https://www.garagedoorsonline.co.uk/cat ... edar/g/230

The principal demands of this garage door are security and durability (by durable I mean to be used daily). My current door is a gliderol and I'm not remotely happy with it. It could be peeled open with a recip saw in a matter of seconds. The door will be used in conjunction with a garage door defender, and probably two locks and a slide across bolt from the back for when I'm away.

The appearance of the wood itself isn't a concern as it is to be painted black. I

The dimensions of the opening are 2285mm wide and 2135mm high.

What I'm struggling to rationalise is:

Thank you in advance!

Mum has to sign off on this one! The design she likes is found here: https://www.garagedoorsonline.co.uk/cat ... edar/g/230

The principal demands of this garage door are security and durability (by durable I mean to be used daily). My current door is a gliderol and I'm not remotely happy with it. It could be peeled open with a recip saw in a matter of seconds. The door will be used in conjunction with a garage door defender, and probably two locks and a slide across bolt from the back for when I'm away.

The appearance of the wood itself isn't a concern as it is to be painted black. I

The dimensions of the opening are 2285mm wide and 2135mm high.

What I'm struggling to rationalise is:

Is Cedar the best wood (strength, stability, cost)?

What thickness should I be aiming for on the styles and rails?

What thickness should I be aiming for on the raised panels (before routing the profile)

I'd ideally be looking for a hinge that has some fine adjustment, just because this design of door, as far as I can tell would be vulnerable to sagging. I quite like a Soss hinge for appearance of the closed door and it strikes me as a secure option. Is this a valid assumption? Is there a better suited hinge for this purpose that isn't large from the outside?

If anyone here has made a few similar doors, I'd love a rough cost estimate on materials based on what you think is suitable as I'm a bit lost on that front right now (plus minus £50 or so).

I see this as a 2.5/3 day project. Does this seem likely?

Thank you in advance!