Halo Jones

Established Member

For my FILs 70th in September we bought him an electric piano/organ. My wife wasn't entirely happy as it was just a standard plastic box type keyboard and didn't really fit in with the rest of his furniture. I was therefore "commissioned" to make a stand/enclosure for it. A bit nervous because this is my first crack at a proper piece of furniture. It looks like it might just about be working out so I am daring to post a WIP. Also nervous about this as despite following this and other woodworking forums since approx 2010 this is my first WIP!

Looking at lots of stands for electric pianos we decided that we would use this as our inspiration - the Roland Kiyola:

I am not doing anything quite as ambitious but it is the inspiration.

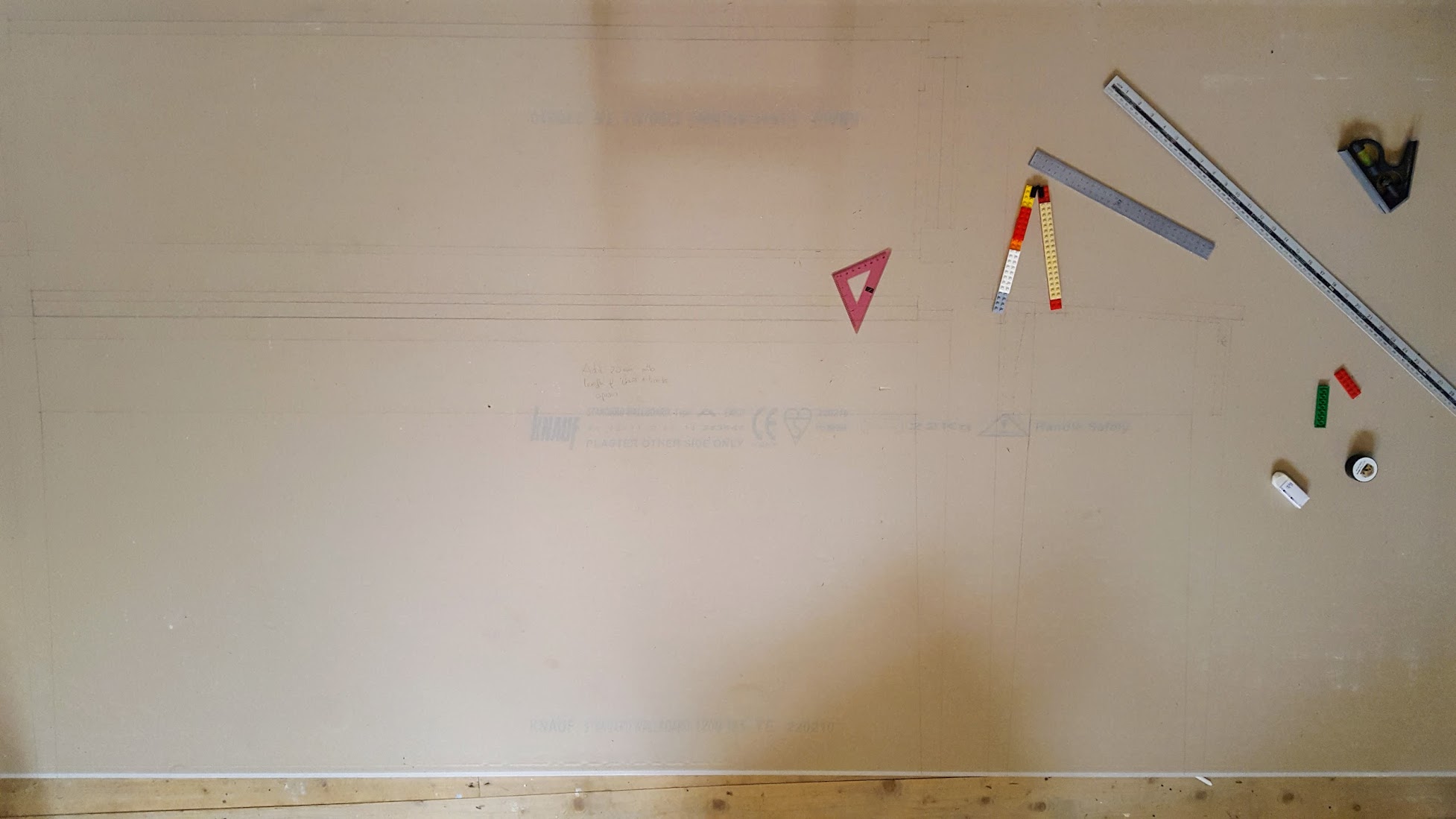

Started with some sketches before moving onto a full size drawing - using my children's lego to work out where the hinge for the top needed to be!

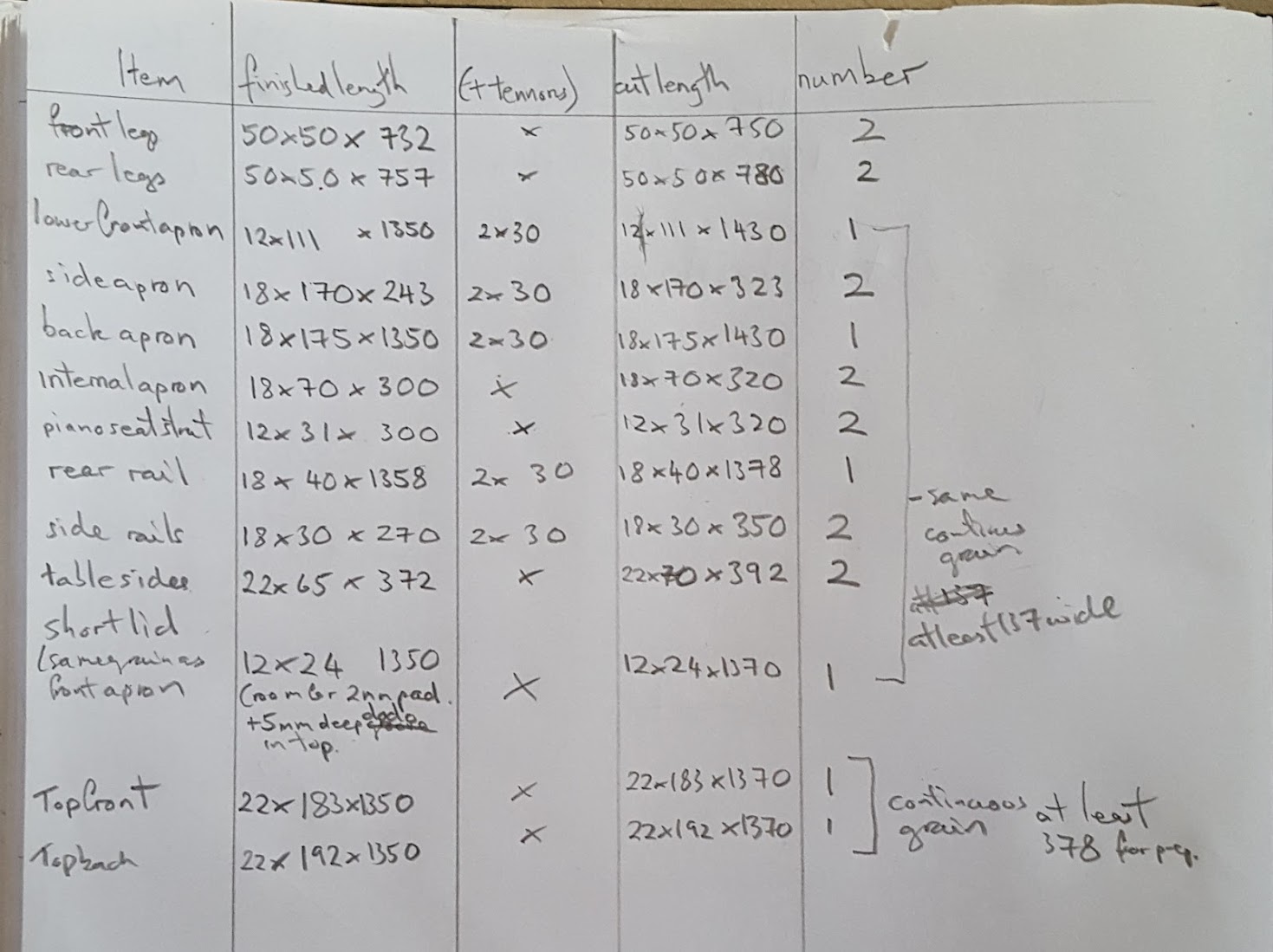

Then I made a cut list:

Before heading to the timber yard. I have used this timber yard before but always placed an order and just picked up. I was advised this time that I should just turn up and choose my timber. I was a bit overwhelmed to be honest but I was left to my own devices and after 90 mins I loaded the car and ended up with:

I rough cut this:

Finding all the defects that I hadn't spotted at the yard and started worrying that I didn't have enough timber:

but there was some nice quarter sawn pieces.

I then set about prepping all the timber with so much enthusiasm that I I completely filled the CamVac and killed one of the motors . Anyhoo, I was left with:

. Anyhoo, I was left with:

More to follow!

Looking at lots of stands for electric pianos we decided that we would use this as our inspiration - the Roland Kiyola:

I am not doing anything quite as ambitious but it is the inspiration.

Started with some sketches before moving onto a full size drawing - using my children's lego to work out where the hinge for the top needed to be!

Then I made a cut list:

Before heading to the timber yard. I have used this timber yard before but always placed an order and just picked up. I was advised this time that I should just turn up and choose my timber. I was a bit overwhelmed to be honest but I was left to my own devices and after 90 mins I loaded the car and ended up with:

I rough cut this:

Finding all the defects that I hadn't spotted at the yard and started worrying that I didn't have enough timber:

but there was some nice quarter sawn pieces.

I then set about prepping all the timber with so much enthusiasm that I I completely filled the CamVac and killed one of the motors

More to follow!