ratkinsonuk

Established Member

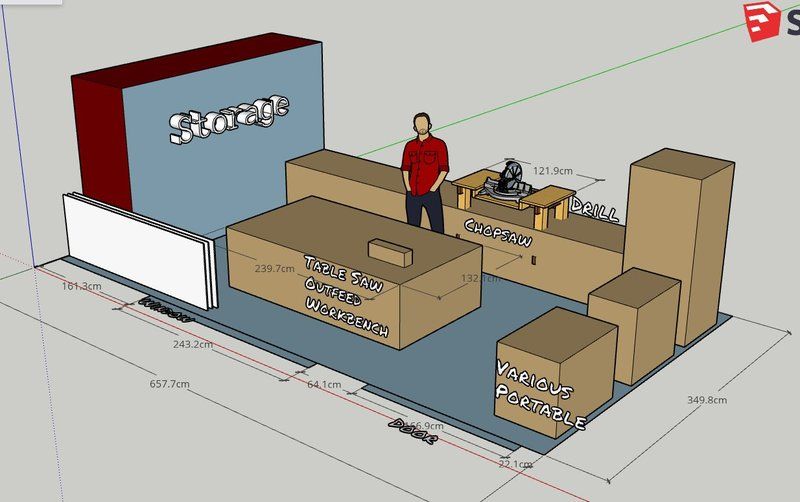

After many years of neglect, I'm going to 'properly' set up my workshop, but I've got a bit of chicken and egg situation going on regarding the basic sequence. Do I concentrate on getting tools set up first, e.g. table saw outfeed, chop saw station, etc, or do I work towards storage first?

If I start with storage, then making cupboards, drawers, etc, is going to be a chore and potentially innacurate. If I go for tool configuration, I'll be constantly working in a tight mess until I reach a certain point and can then turn my attention to storage projects.

I suspect the optimum answer is going to be a balance of both - get the table saw station up and running, then build a bit of storage to clear one of the walls of clutter, then work on a chop-saw section, followed by some more storage.

Any additional comments or sage advice?

If I start with storage, then making cupboards, drawers, etc, is going to be a chore and potentially innacurate. If I go for tool configuration, I'll be constantly working in a tight mess until I reach a certain point and can then turn my attention to storage projects.

I suspect the optimum answer is going to be a balance of both - get the table saw station up and running, then build a bit of storage to clear one of the walls of clutter, then work on a chop-saw section, followed by some more storage.

Any additional comments or sage advice?