Made these to replace the crappy plastic Axminster offering. Thanks to the person who posted their wooden version (I couldn't find it again to link to)

I planed up some 15mm oak. Set the circle jig up to the overall width and routed half the depth.

I used a pillar drill to transfer the centre hole to the other side, then set the jig to a smaller diameter (to form the rebate) and routed again.The circle jig works by just pivoting on a magnet so the drilled hole needed to be small enough to still hold a screw.

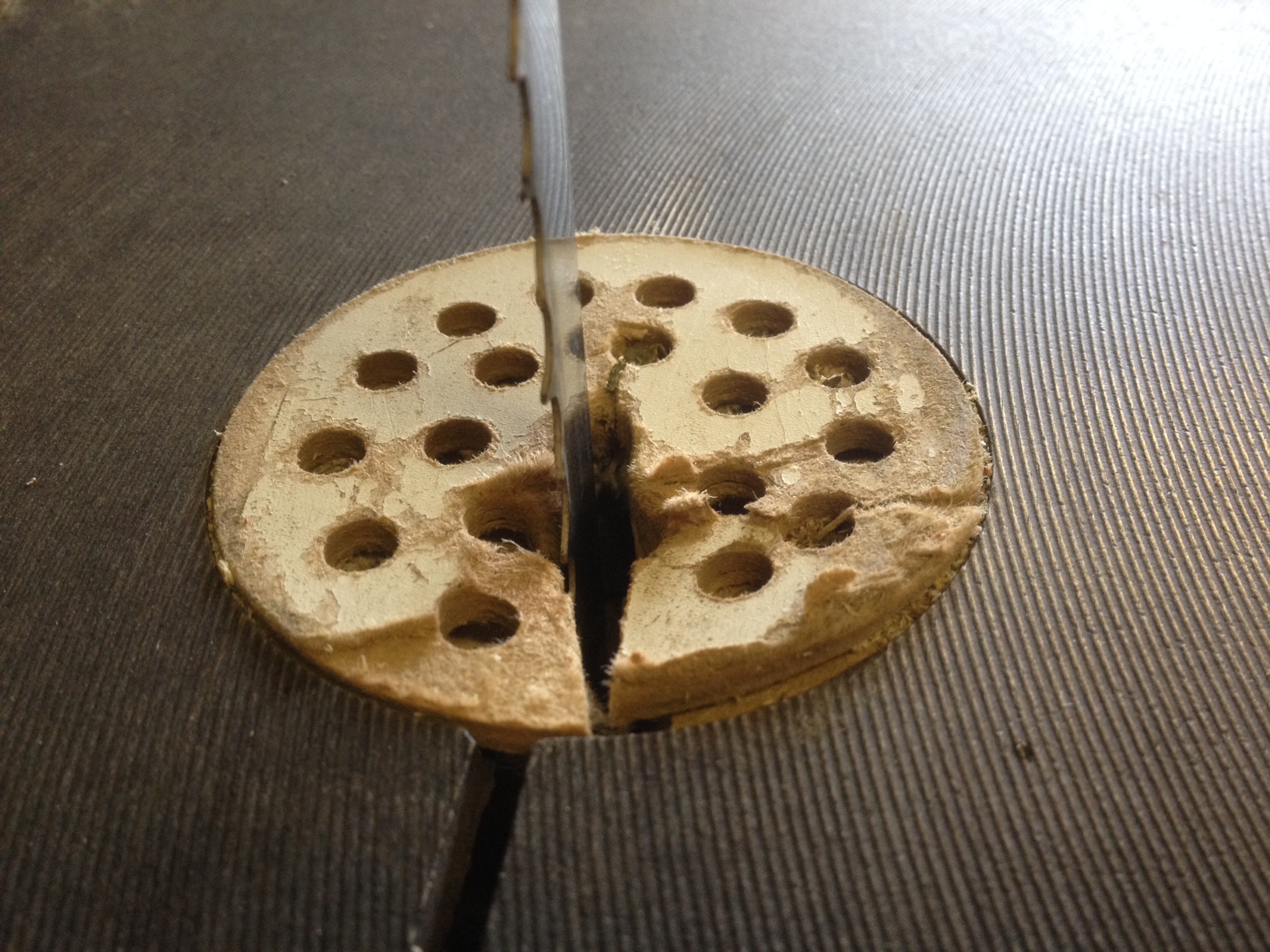

All it then needed was the slot cutting and a notch from the underside to fit in the table.

It took a couple hours, but I'm fairly sure these should outlast the poorly made overpriced Axminster offerings. I realise that sounds harsh, but think their plastic design is prone to failure-cause it's riddled with unecessary weakening holes and only 4mm thick.

Time will tell if these are any better.

Coley

I planed up some 15mm oak. Set the circle jig up to the overall width and routed half the depth.

I used a pillar drill to transfer the centre hole to the other side, then set the jig to a smaller diameter (to form the rebate) and routed again.The circle jig works by just pivoting on a magnet so the drilled hole needed to be small enough to still hold a screw.

All it then needed was the slot cutting and a notch from the underside to fit in the table.

It took a couple hours, but I'm fairly sure these should outlast the poorly made overpriced Axminster offerings. I realise that sounds harsh, but think their plastic design is prone to failure-cause it's riddled with unecessary weakening holes and only 4mm thick.

Time will tell if these are any better.

Coley