Jacob

Pint of bass, porkpie, and packet of crisps please

Not really. Easy enough to make a few holes in the apron if you really want to use your bench with F clamps that way, but there are many other ways of doing the same thing - a holdfast for starters . But a table would do for routing - a big sturdy bench not necessary.custard":17z4o6k3 said:.......

You could do the job at the router table or spindle moulder, but that's more of a faff. Quickest and easiest is right at your bench.

That's the key reason against a Nicholson style bench.

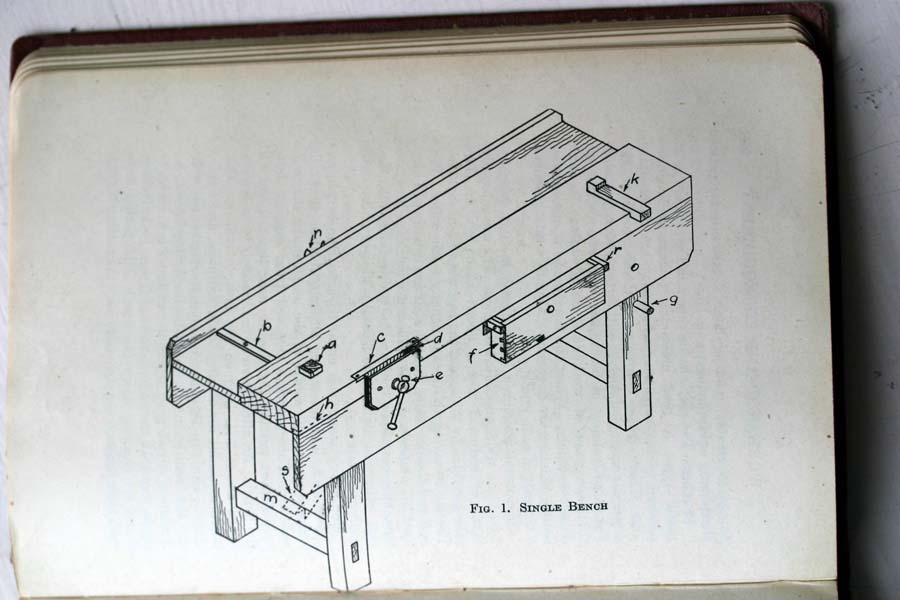

The key reason is just fashion IMHO. The trad bench barely features in the various well known modern bench books and it's only because a bench by Nicholson features in one of them that it is now known as the "Nicholson" bench. Nobody had heard of him or his bench in the old days, unless they were into woodwork history - in which case they would also be well aware of the trad bench design common before the fashion kicked off, as they feature in most of the old books - just known as "woodwork bench".