Progress.

I'd used rasps and files to do the final shaping some time ago. I shaped the #4 handles to be similar to the plastic handle from my modern #4, but I've noticed that the older #4 model often has a really thin top rear (somewhat like a horn). I really like that, but it would be more vulnerable to damage.

I decided to attack the top/rear section again. I didn't want to take out too much, but in comparison to the unmodified one below it is a bit thinner:

Lots of sanding later, we have a full compliment of two #4 handles, two #4 1/2 / #5 / #5 1/2 handles, two tall knobs and two short knobs (the knobs were turned by my dad). On the left are a beech pair from a Record #3:

And wiped down with some white spirit:

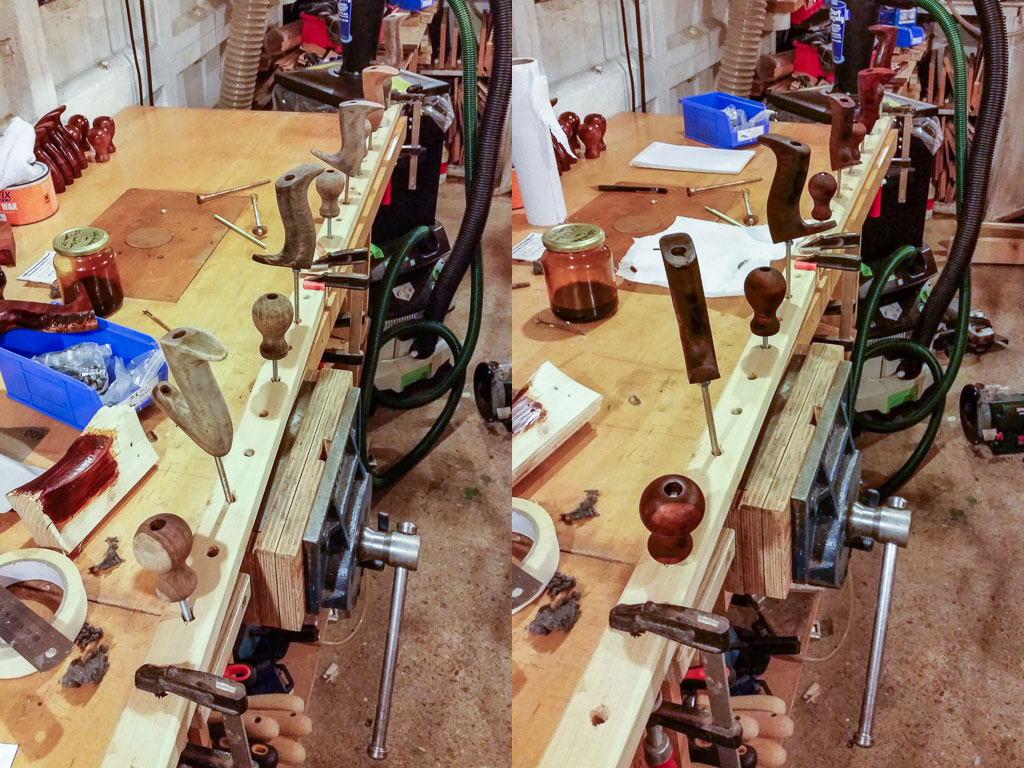

A DIY clamp with some M6 bolts and nuts re-purposed as a stand (in the background you can see some of the original handles and knobs, now sanded):

First coat of Danish Oil - looking good:

24 hours later, a light rub with some 0000 steel wool, and coat #2 now looking really good:

The DO images above are wet (so very shiny). However, I've noticed that even once dry, they're much better than the test pieces I'd done. I think I probably didn't spent enough time sanding the test blocks to the same surface finish as the actual handles and knobs.

Unfortunately the beech front knob and rear handle came out different colours once oiled. I understand they would have originally been stained dark brown (a previous owner had removed the coating before I bought the #3).

I've got some brown leather dye that I've mixed with shellac that I'm going to use on the old handles and knobs; as whilst they've sanded off OK the actual wood isn't that impressive, and they're a bit patchy - hence I felt a dyed shellac would be better than DO. I'll just use the tinted shellac on the beech parts and leave the single coat of DO on. I don't immediately need the other handles (apart from one pair for a #4 1/2, and the beech ones for the #3) but it seemed a good idea to restore them as they might prove useful in the future.