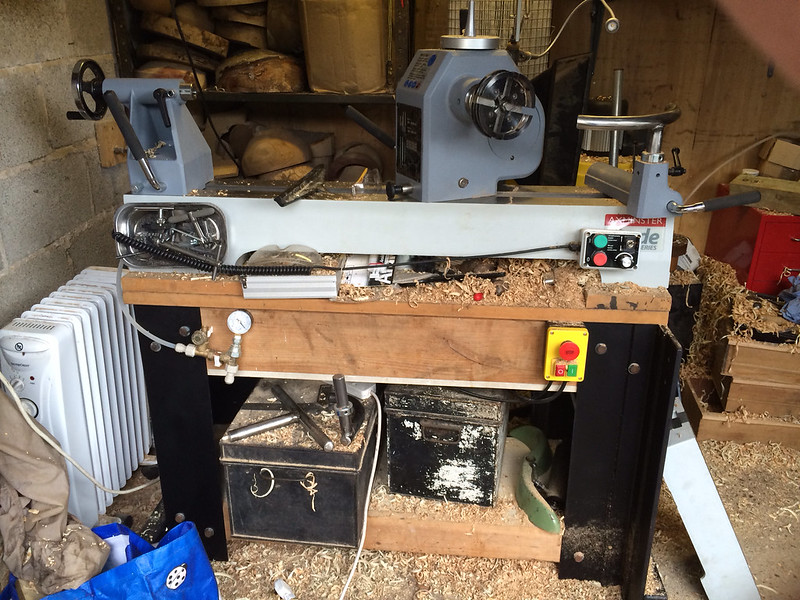

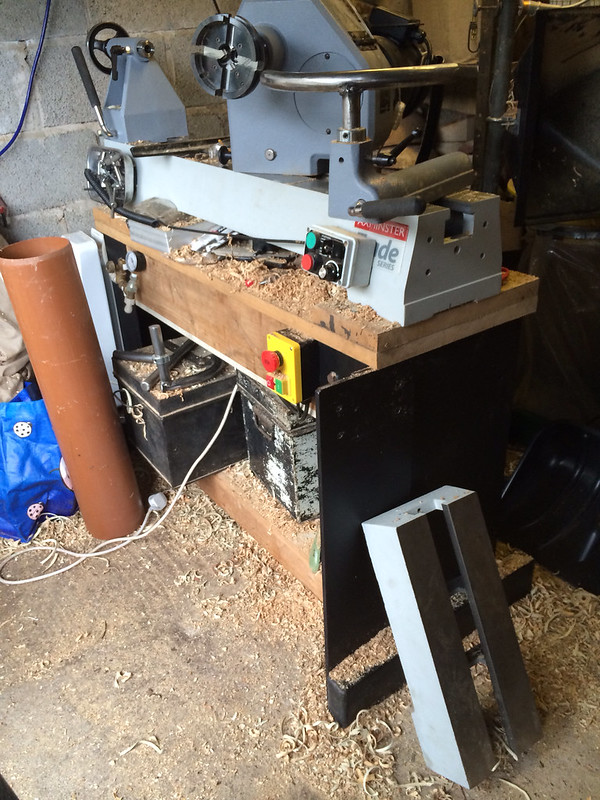

OK, off that call so I have 5 mins. The outriger is made largely from scaffolding tube. The holes in the casting for the original bed extension are scaffolding diameter (which is a standard tube size) which I think is 48.3mm???). The fittings are either scaffolding or railing (for scaffold diameter tubes) fittings. Scaffold pipes are nominal and many are slightly oversize so some light grinding of the tubes may be required to fit them through the casting.

The only bit I needed to get made was an extension tube to raise the toolrest from bango height.

Scaffold tubes are rough and I did sometimes have issues with the banjo rocking. The solution to this is to either get non-galvanized tube of the right diameter. I still have the original bed bars and these would be ideal although they are a little rusty as they were in the rain for a couple of days.

Another option is to find a new banjo and get a bed extension from another lathe. I suspect this would be a better solution. I have done something similar on my new lathe. I reused the Poolewood bench (cut down, wider stance with adjustable feet, beefed up one end panel and added drop extension bed there. I have found this solution to work really well. I can probably take a photo of that later in the day if it will help.

I have promised another forum member first dibs on the parts (I have not forgotten, just been busy) but the riser may be available if you wanted to take the scaf route. A also have all the fittings and the bars but heavy to post and they have some value to me for other projects.

BM