Rhyolith

Established Member

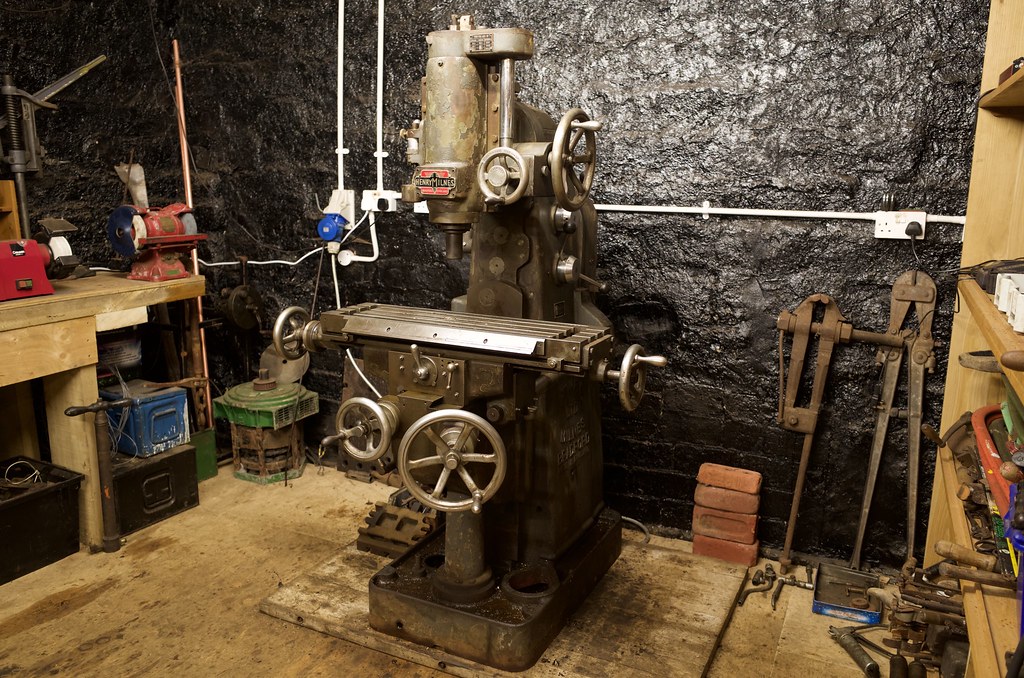

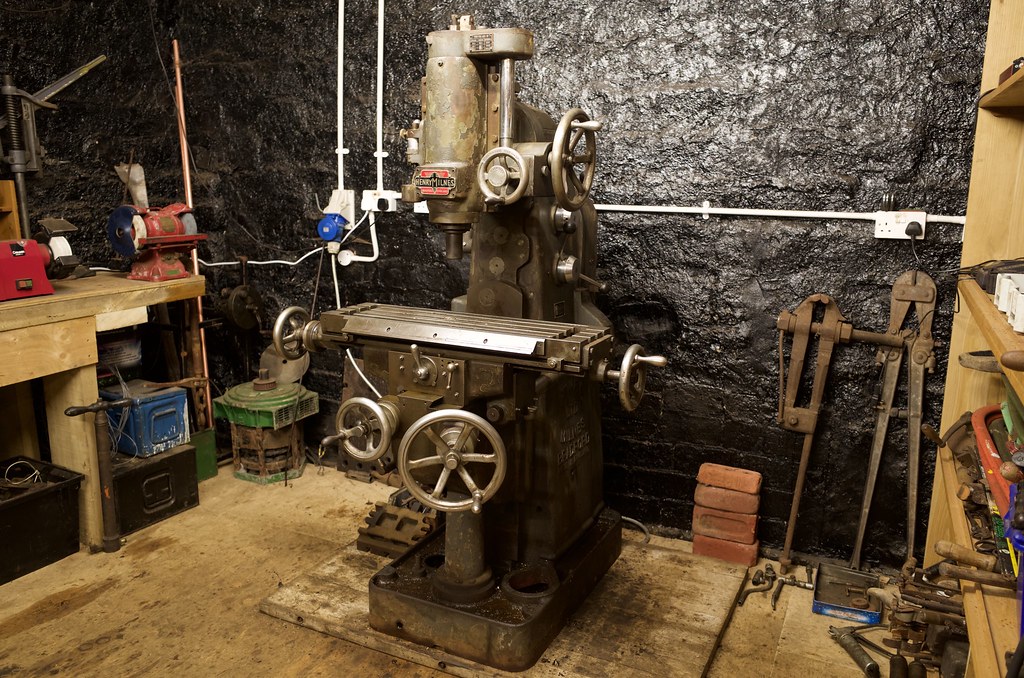

wallace and his Wadkin lathe (wadkin-rs-restoration-t109909.html) inspired me to make a thread specifically dedicated to my restoration attempts of my first large industrial machine. This kinda follows on from this thread: milling-machine-for-steam-engines-t108613.html?start=15 but all elements of the restoration will be covered here, will try to keep them in chronological order.

Its a Toolroom vertical mill, dating from the 1940s-50s: http://www.lathes.co.uk/milnesmiller/

This is what it looked like when it first arrived in my workshop:

Henry Milnes Milling Machine by Rhyolith, on Flickr

Henry Milnes Milling Machine by Rhyolith, on Flickr

Henry Milnes Milling Machine by Rhyolith, on Flickr

Henry Milnes Milling Machine by Rhyolith, on Flickr

Henry Milnes Milling Machine by Rhyolith, on Flickr

Henry Milnes Milling Machine by Rhyolith, on Flickr

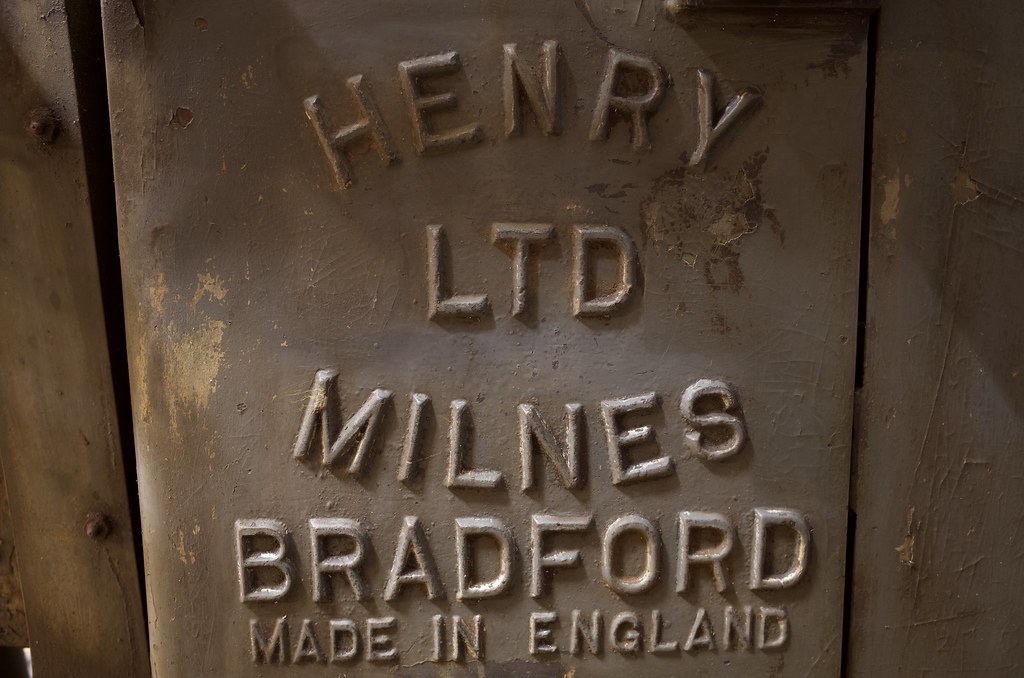

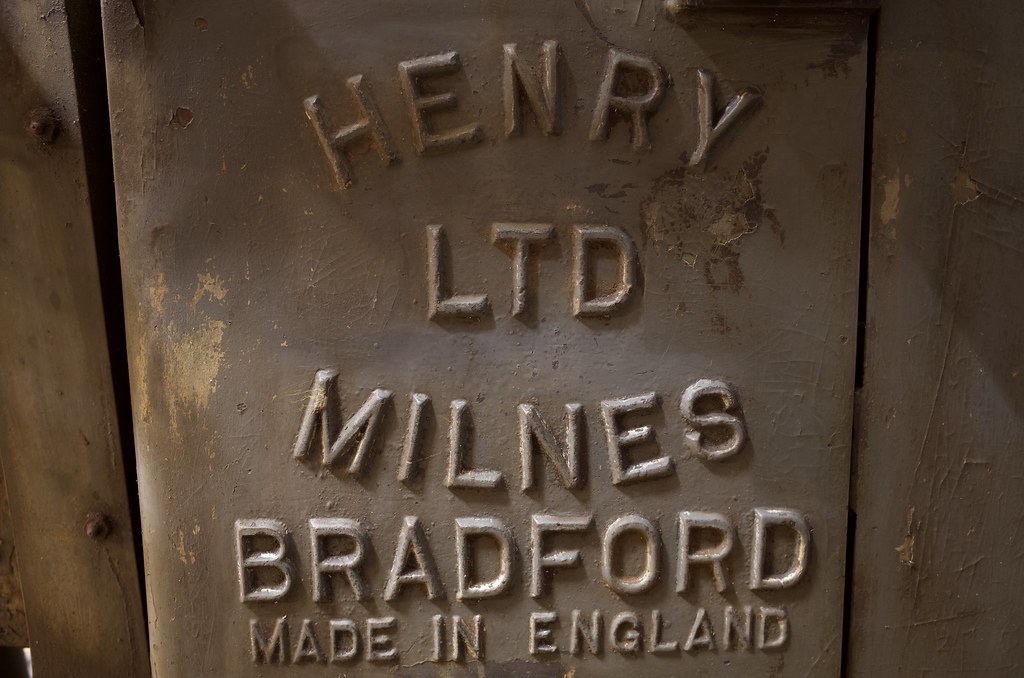

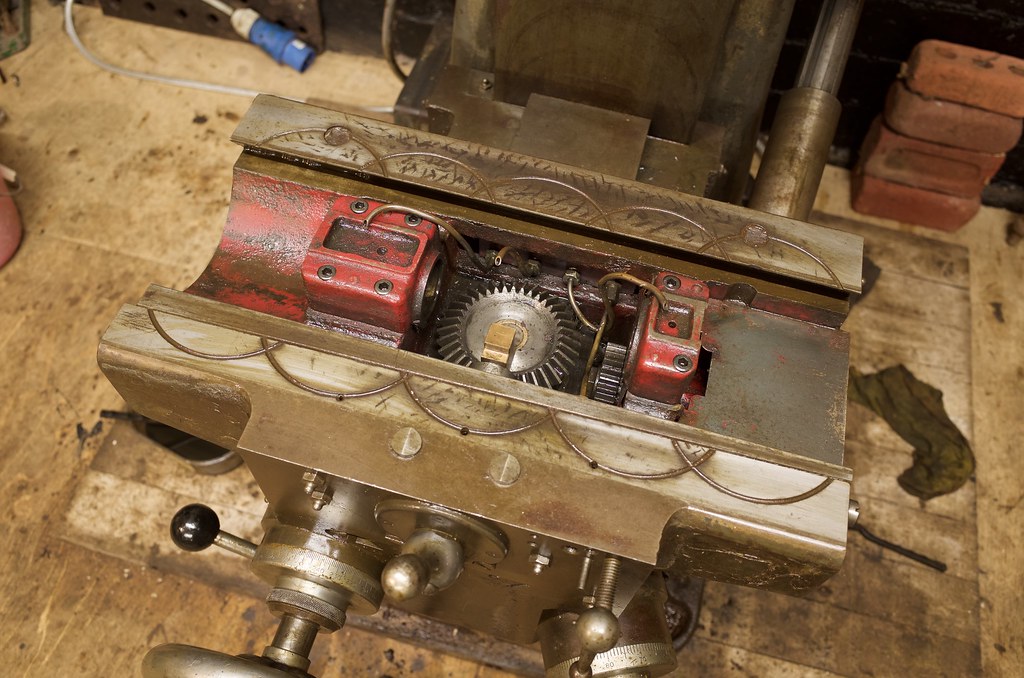

First thing I did was wash it down with paraffin, rags, wire wool and wire brushes. Mainly just so I could see what was there! After that (which took a while) it looked like this:

Henry Milnes Milling Machine by Rhyolith, on Flickr

Henry Milnes Milling Machine by Rhyolith, on Flickr

Henry Milnes Bradford by Rhyolith, on Flickr

Henry Milnes Bradford by Rhyolith, on Flickr

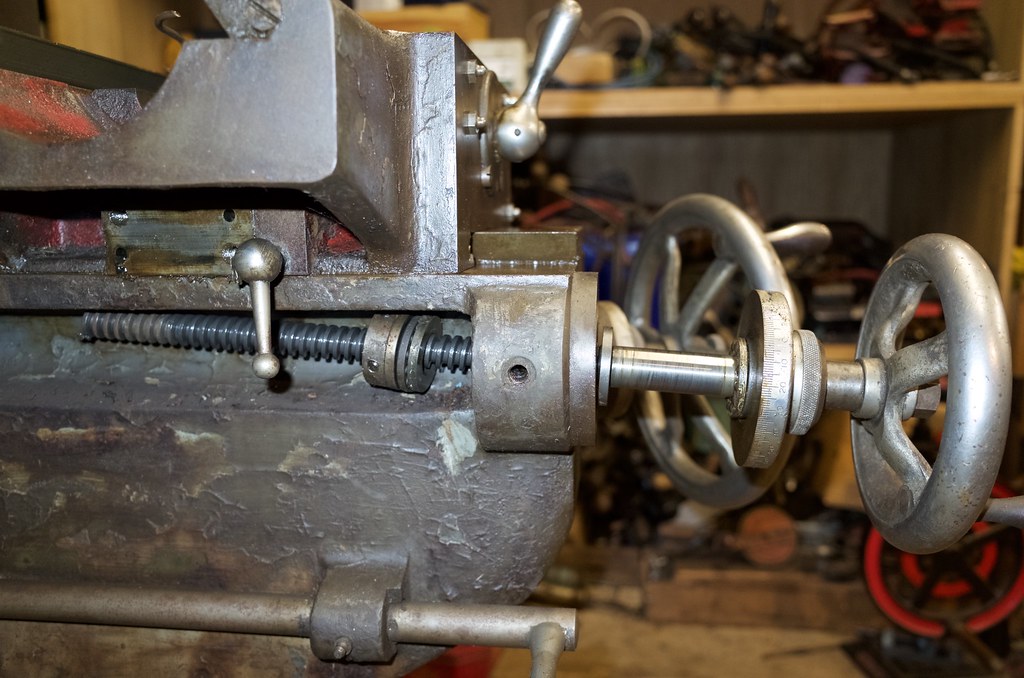

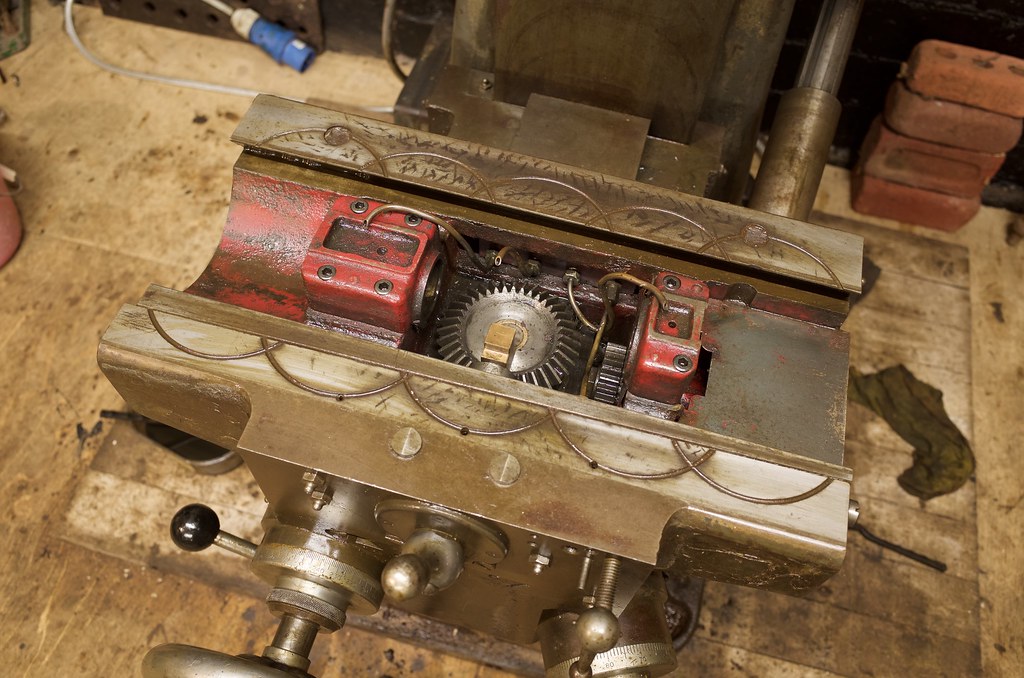

Next started to examine it for mechanical issues. The first obvious issue was the table side to side movement was stiff, so started dismantling that.

Under the Bed by Rhyolith, on Flickr

Under the Bed by Rhyolith, on Flickr

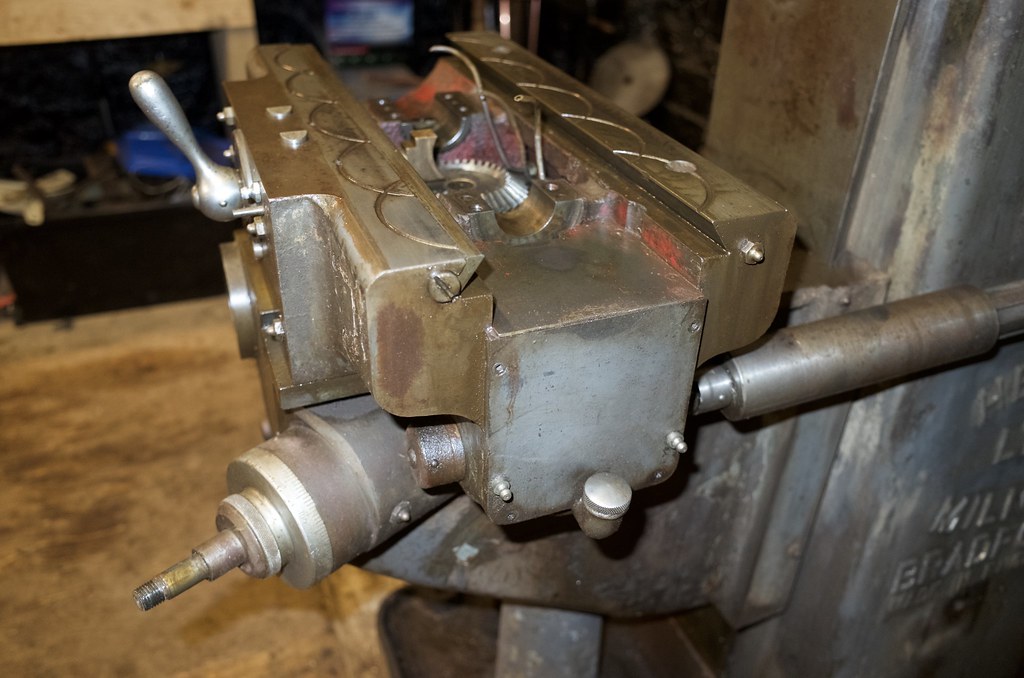

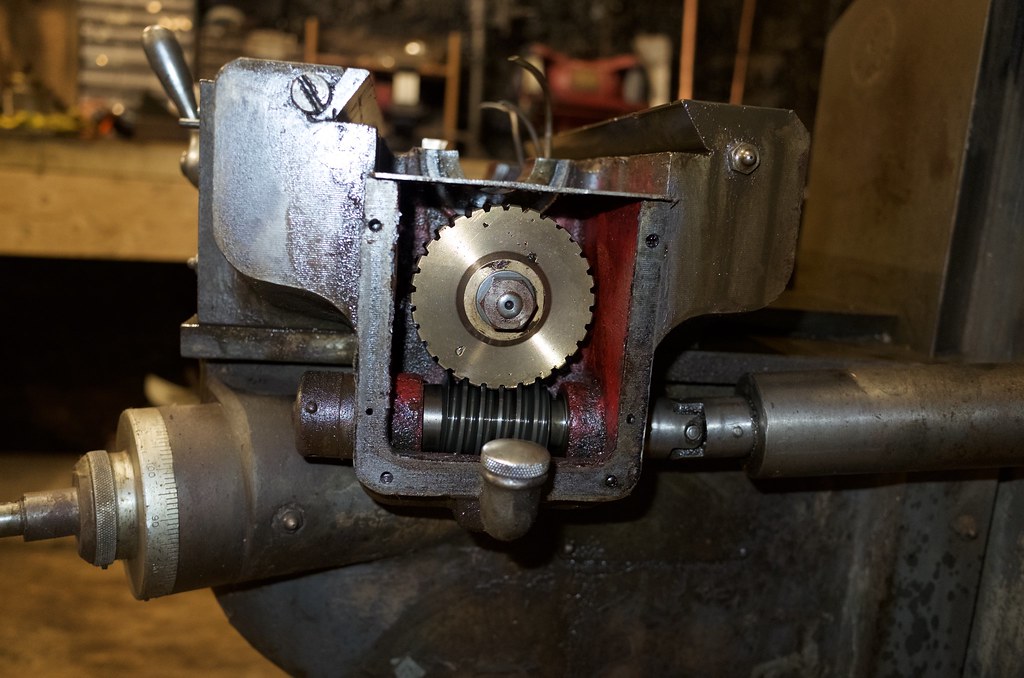

This bearing was clearly stiff (possibly the problem) but I could not get into it without a specialised spanner for these nuts of a sort I have never seen before.

Table Drive Nuts by Rhyolith, on Flickr

Table Drive Nuts by Rhyolith, on Flickr

I think the required tool is a "hook" spanner... anyway I found this on eBay recently which finally allowed for progress!

Willaims Adjustable Hook Spanner by Rhyolith, on Flickr

Willaims Adjustable Hook Spanner by Rhyolith, on Flickr

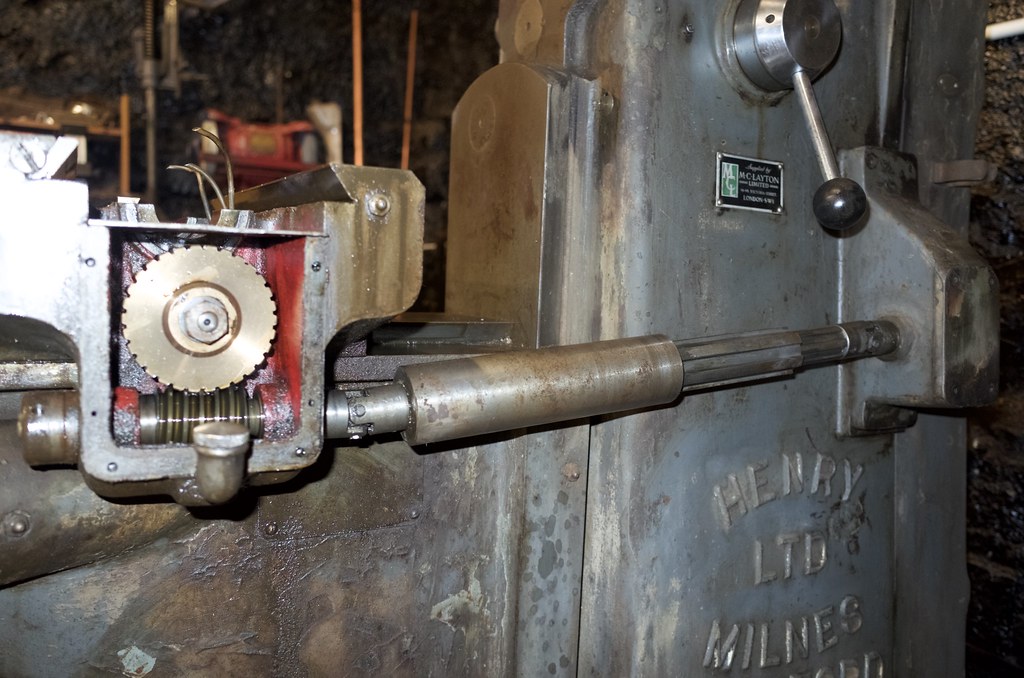

That worked and the whole winding assembly is not in bits, I think the nuts where actually the problem, they were too tight. All the same the whole lot will be cleaned and re-lubricated before re-assmbly.

That takes it to today, where I wanted to try and get at the winding mechanism for lifting the table, which is a tad stiff I think. Almost immediately I find a nut that needs another type of hook spanner... back to eBay :roll:

Table Depth Adjuster by Rhyolith, on Flickr

Table Depth Adjuster by Rhyolith, on Flickr

Its a Toolroom vertical mill, dating from the 1940s-50s: http://www.lathes.co.uk/milnesmiller/

This is what it looked like when it first arrived in my workshop:

Henry Milnes Milling Machine by Rhyolith, on Flickr

Henry Milnes Milling Machine by Rhyolith, on Flickr Henry Milnes Milling Machine by Rhyolith, on Flickr

Henry Milnes Milling Machine by Rhyolith, on Flickr Henry Milnes Milling Machine by Rhyolith, on Flickr

Henry Milnes Milling Machine by Rhyolith, on FlickrFirst thing I did was wash it down with paraffin, rags, wire wool and wire brushes. Mainly just so I could see what was there! After that (which took a while) it looked like this:

Henry Milnes Milling Machine by Rhyolith, on Flickr

Henry Milnes Milling Machine by Rhyolith, on Flickr Henry Milnes Bradford by Rhyolith, on Flickr

Henry Milnes Bradford by Rhyolith, on FlickrNext started to examine it for mechanical issues. The first obvious issue was the table side to side movement was stiff, so started dismantling that.

Under the Bed by Rhyolith, on Flickr

Under the Bed by Rhyolith, on FlickrThis bearing was clearly stiff (possibly the problem) but I could not get into it without a specialised spanner for these nuts of a sort I have never seen before.

Table Drive Nuts by Rhyolith, on Flickr

Table Drive Nuts by Rhyolith, on FlickrI think the required tool is a "hook" spanner... anyway I found this on eBay recently which finally allowed for progress!

Willaims Adjustable Hook Spanner by Rhyolith, on Flickr

Willaims Adjustable Hook Spanner by Rhyolith, on FlickrThat worked and the whole winding assembly is not in bits, I think the nuts where actually the problem, they were too tight. All the same the whole lot will be cleaned and re-lubricated before re-assmbly.

That takes it to today, where I wanted to try and get at the winding mechanism for lifting the table, which is a tad stiff I think. Almost immediately I find a nut that needs another type of hook spanner... back to eBay :roll:

Table Depth Adjuster by Rhyolith, on Flickr

Table Depth Adjuster by Rhyolith, on Flickr