You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fitting Rebate Block On Spindle Moulder Spacer Question

- Thread starter pollys13

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Jacob

Pint of bass, porkpie, and packet of crisps please

10mm is a small gap and may trap chippings in the well.

I'd just go for no rings and see how it goes. I can't see a problem unless you are doing very short pieces, especially if you are using a power feed.

I'd just go for no rings and see how it goes. I can't see a problem unless you are doing very short pieces, especially if you are using a power feed.

Uum, OKJacob":2v9am55s said:10mm is a small gap and may trap chippings in the well.

I'd just go for no rings and see how it goes. I can't see a problem unless you are doing very short pieces, especially if you are using a power feed.

Trevanion

Greatest Of All Time

pollys13":g116h9ek said:OK even though I'm using a power feed, as an extra safety measure. I think I should close the gap up by making a ring up. What size gap should I allow for between the back knife and ring to avoid the knife catching and adequate chip extraction?

Cheers.

You can go quite tight. You won't "catch" chippings as those new style rebate blocks aren't really capable of producing any large solid chips as the older ones could, even if they did it wouldn't go anywhere near the ring it would just get sucked out of the top port. 2-3mm would be plenty.

OK cheers.Doug71":lek3uyc3 said:You will be fine with no ring, in fact I would feel safer with no ring than with a homemade plywood one.

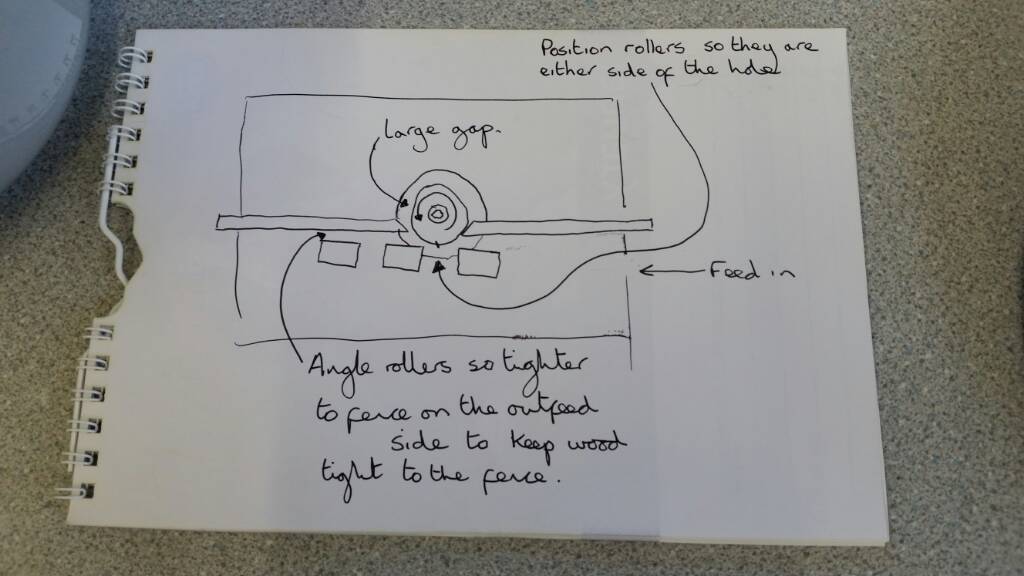

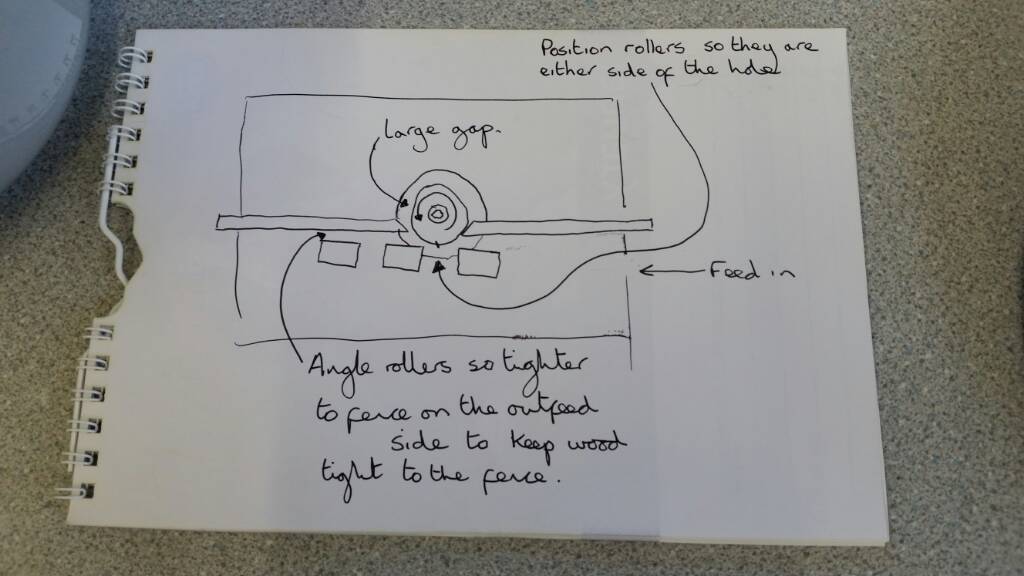

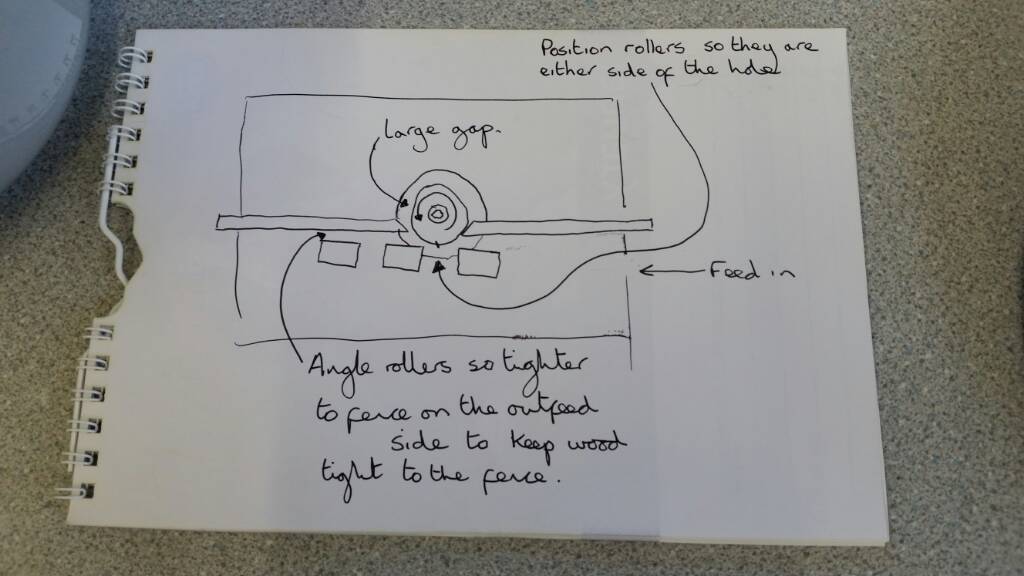

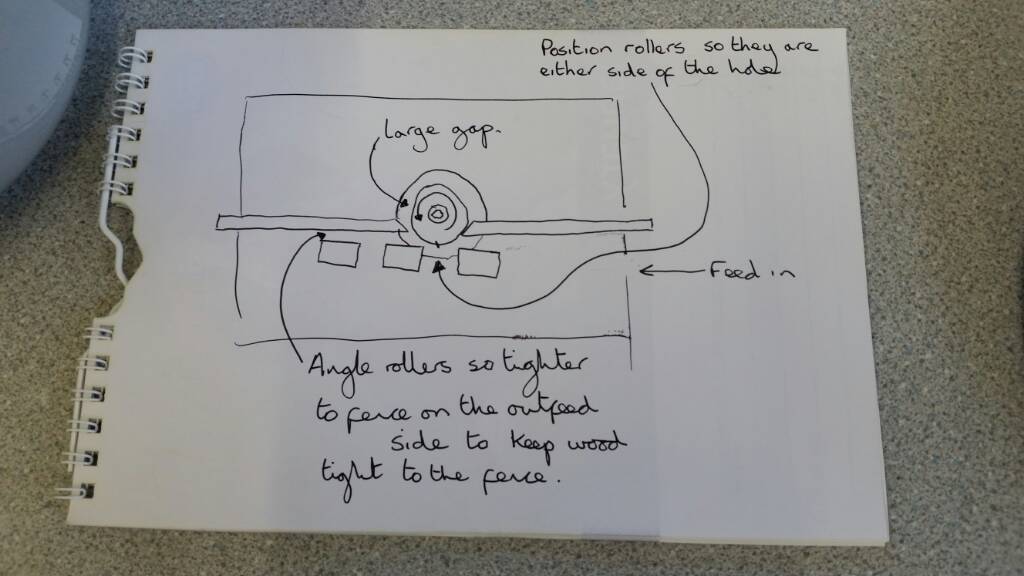

With a large gap and the rollers set up correctly it should be pretty difficult to get the wood to fall in the gap.

The first rollers already pushing down on the wood so it shouldn't want to go in the gap.

Sent from my SM-G900F using Tapatalk

The first rollers already pushing down on the wood so it shouldn't want to go in the gap.

Sent from my SM-G900F using Tapatalk

Cheers Coley, mateColeyS1":2zdrf4wa said:With a large gap and the rollers set up correctly it should be pretty difficult to get the wood to fall in the gap.

The first rollers already pushing down on the wood so it shouldn't want to go in the gap.

Sent from my SM-G900F using Tapatalk

Jacob

Pint of bass, porkpie, and packet of crisps please

Yep.ColeyS1":2ncvvnol said:With a large gap and the rollers set up correctly it should be pretty difficult to get the wood to fall in the gap.

The first rollers already pushing down on the wood so it shouldn't want to go in the gap.

Sent from my SM-G900F using Tapatalk

And you get better dust extraction. Bigger machines have another extractor port in the well but you are still better off not closing the gap much, if at all, unless it's a very big machine with a wide well.

Happy to help Pollys13

Must admit Jacob that took me years to get my head around. I always use to think the smaller the extractor hose the more suction. I also use to think the smaller the gaps the greater the suction. It's all about airflow though. Get as much air moving as possible to clear the chips and get them flowing in the right direction. Polly, think of a wide open front and back door on a windy day vs just the front door open- it'd still get the air moving but nothing like having both open (some nice gaps)

Sent from my SM-G900F using Tapatalk

Must admit Jacob that took me years to get my head around. I always use to think the smaller the extractor hose the more suction. I also use to think the smaller the gaps the greater the suction. It's all about airflow though. Get as much air moving as possible to clear the chips and get them flowing in the right direction. Polly, think of a wide open front and back door on a windy day vs just the front door open- it'd still get the air moving but nothing like having both open (some nice gaps)

Sent from my SM-G900F using Tapatalk

Similar threads

- Replies

- 5

- Views

- 3K

- Replies

- 6

- Views

- 1K