Hi,

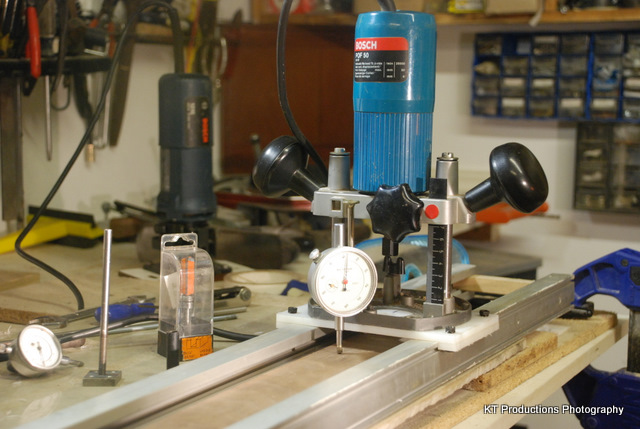

I've just got Rob Wearing's book on "Router Tips and Techniques". I notice he has a a Bosch POF52 (shown in a number of illustrations), above the left hand plunge column of which is affixed what looks like a tube surmounted by a knurled knob. The function of this accessory isn't described, but I'm wondering if it is a fine-height adjuster.

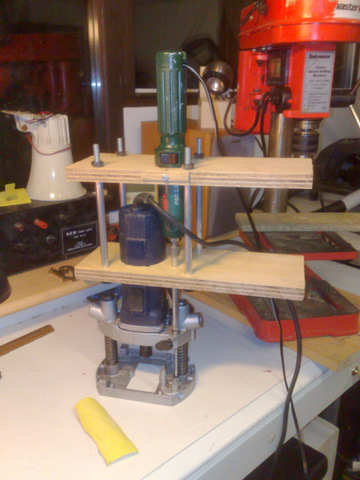

I've got a POF500A. I've been pondering for a while how best to make a fine adjustment device for it (the M10 depth stop assembly is a little coarse for this purpose, for my taste) The plunge column on the POF500A which corresponds to the POF52 column has a short M6 threaded hole at the top, onto which a washer is held by an M6 bolt: this stops the motor assembly lifting off the plunge base !.

I'm prompted by the photo in Rob Wearing's book to wonder if this threaded hole can be used to make a fine-height adjuster - indeed, whether the device shown in Rob Wearing's book is just such an adjuster.

Can anybody assist? Is such a device commercially available for this router type? Am I right in thinking the pictures in RW's book do indeed show a FH adjusted? Have any of you made, or used, such a device for this type of router.

Thanks for any info you can give me.

Chris

I've just got Rob Wearing's book on "Router Tips and Techniques". I notice he has a a Bosch POF52 (shown in a number of illustrations), above the left hand plunge column of which is affixed what looks like a tube surmounted by a knurled knob. The function of this accessory isn't described, but I'm wondering if it is a fine-height adjuster.

I've got a POF500A. I've been pondering for a while how best to make a fine adjustment device for it (the M10 depth stop assembly is a little coarse for this purpose, for my taste) The plunge column on the POF500A which corresponds to the POF52 column has a short M6 threaded hole at the top, onto which a washer is held by an M6 bolt: this stops the motor assembly lifting off the plunge base !.

I'm prompted by the photo in Rob Wearing's book to wonder if this threaded hole can be used to make a fine-height adjuster - indeed, whether the device shown in Rob Wearing's book is just such an adjuster.

Can anybody assist? Is such a device commercially available for this router type? Am I right in thinking the pictures in RW's book do indeed show a FH adjusted? Have any of you made, or used, such a device for this type of router.

Thanks for any info you can give me.

Chris