OPJ

Established Member

Hi guys,

Good news is, I have been asked to make dining tables for two different people! In both cases, they will need to extend from four-seaters to six-seater tables. There, drop-leaves are out of the equation as they'd only get in the way of four chairs.

In both cases, they will need to extend from four-seaters to six-seater tables. There, drop-leaves are out of the equation as they'd only get in the way of four chairs.

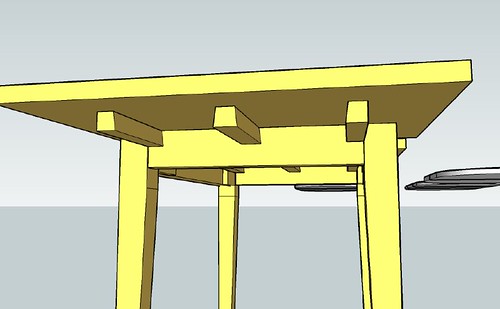

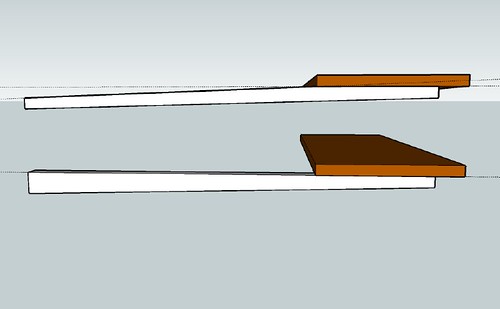

Some kind of extending or 'expanding butterfly' table is what I'm after, where the top slides apart two central sections unfold from below. Trouble is, while I can see how this works and have even found a great design for doing most of this in wood and brass, I'm having trouble getting the proportions right and would appreciate some feedback and advice here.

One of these tables will be my competition entry, by the way. :wink:

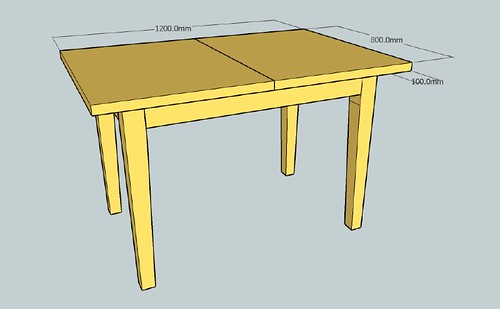

Okay. While I've drawn these out with square ends, it's quite possibly the final design will be move oval-shaped or elliptical... Perhaps I should draw that out first? I'm sure the shape will have some effect on the dimensions of the frame work... :?

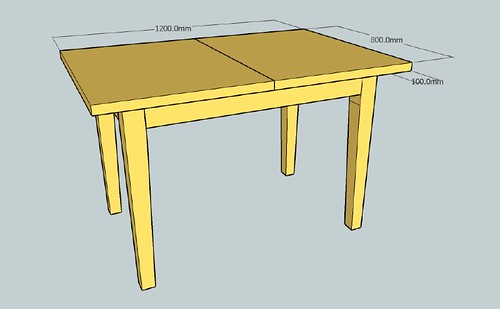

Please ignore the design of the legs and rails for now; it's the top we're most interested in. I've stated off with 100mm overhang at each end.

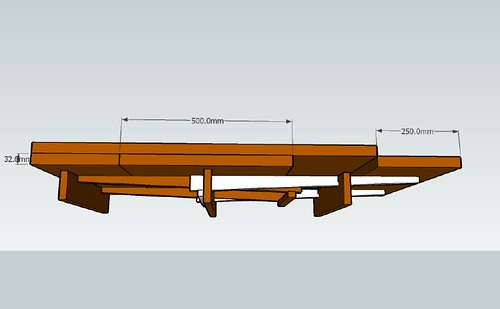

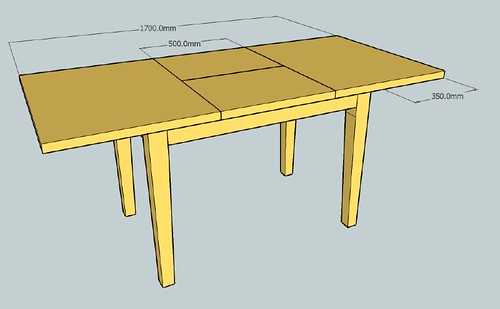

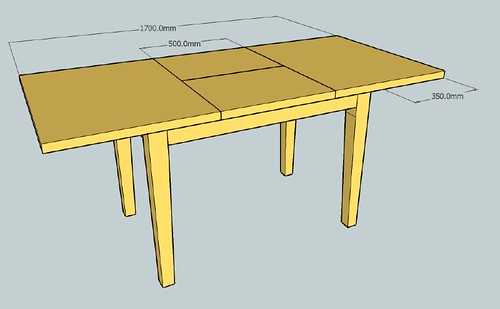

Looking at the second photo, I'm thinking that 350mm overhang is too much? Most sources recommend 600mm as an ideal spacing for one person. I've drawn the central sections at 500mm to try and reduce some of the overhang but, it hasn't made much of a difference...

For what it's worth, the second table I have to make will be slightly shorter than this one in its length. Any thoughts on setting this out correctly would be much appreciated - sadly, that information is lacking in the otherwise excellent I found. :roll:

Also, (DaveR? :wink I'm looking for guides or walkthroughs on drawing ellipses in SketchUp.

I'm looking for guides or walkthroughs on drawing ellipses in SketchUp.

Thanks for reading,

Olly.

Good news is, I have been asked to make dining tables for two different people!

Some kind of extending or 'expanding butterfly' table is what I'm after, where the top slides apart two central sections unfold from below. Trouble is, while I can see how this works and have even found a great design for doing most of this in wood and brass, I'm having trouble getting the proportions right and would appreciate some feedback and advice here.

One of these tables will be my competition entry, by the way. :wink:

Okay. While I've drawn these out with square ends, it's quite possibly the final design will be move oval-shaped or elliptical... Perhaps I should draw that out first? I'm sure the shape will have some effect on the dimensions of the frame work... :?

Please ignore the design of the legs and rails for now; it's the top we're most interested in. I've stated off with 100mm overhang at each end.

Looking at the second photo, I'm thinking that 350mm overhang is too much? Most sources recommend 600mm as an ideal spacing for one person. I've drawn the central sections at 500mm to try and reduce some of the overhang but, it hasn't made much of a difference...

For what it's worth, the second table I have to make will be slightly shorter than this one in its length. Any thoughts on setting this out correctly would be much appreciated - sadly, that information is lacking in the otherwise excellent I found. :roll:

Also, (DaveR? :wink

Thanks for reading,

Olly.