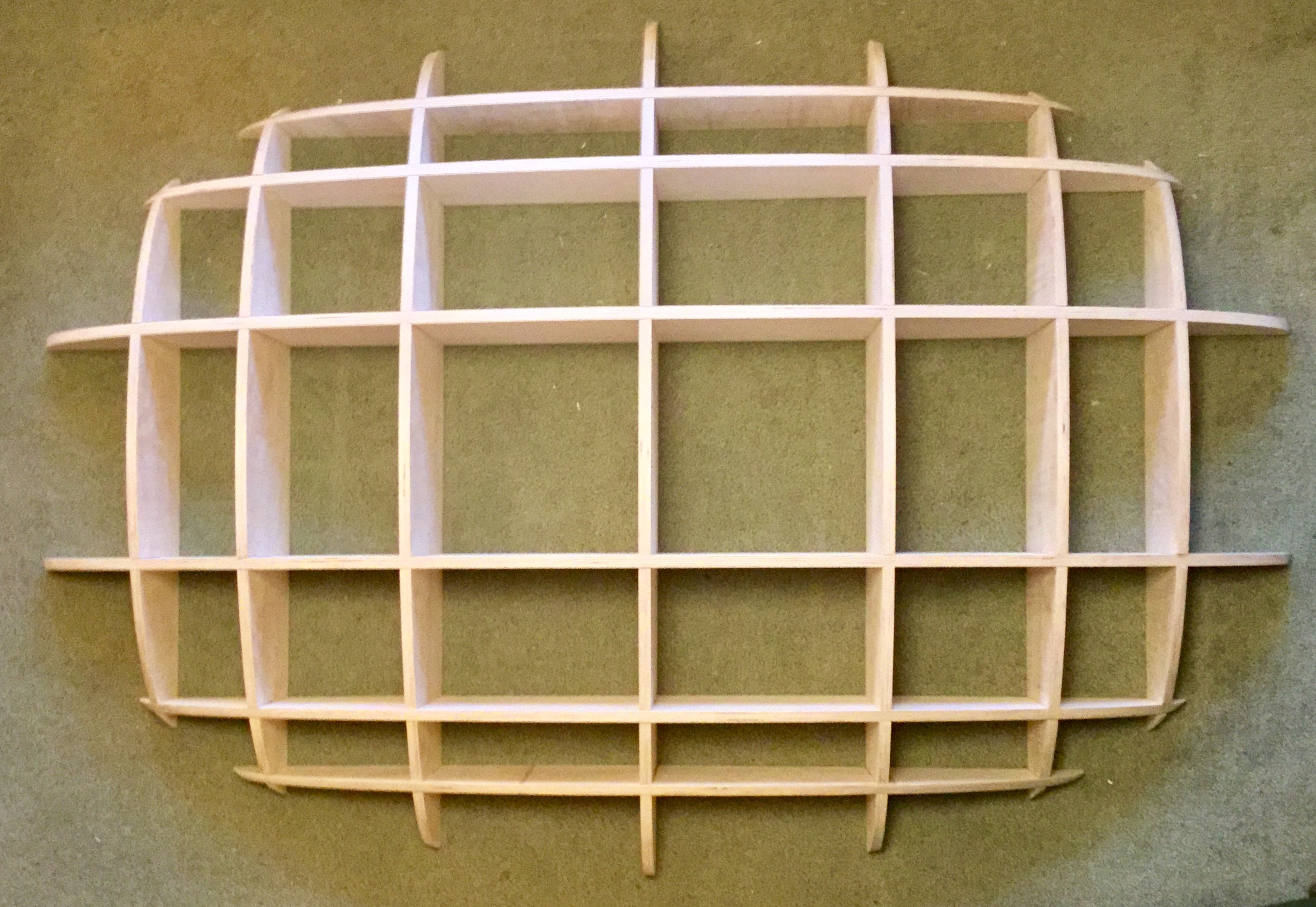

A few thoughts as requested from someone who has hung shelves and cupboards but nothing as sleek as your shelves...

Sloping studs into sloping holes sound good but there's no scope for correcting inaccuracies. You'd need a full size grid/jig which could be drilled through one way to make holes in the shelves then held up to the wall to make matching holes. And still you could hit a stone and knock the whole thing skew.

That said, there are some fixings with an eccentric part which you can rotate. However, if you use more than two, your possible adjustment might not go where you want it.

You might be able to fudge some adjustments using pins which are a loose fit into the shelves, but packing them out.

Think about how the shelves will be seen. If it's from above, then you can hide fixings under the horizontals.

I think I would make or adapt some brass or steel strips, set in to the back and spanning a whole cell or just a corner. Screw from behind, into the edge of the plywood. Countersunk screws from the front hold everything to the wall. Easy to mark out from the front and only need ordinary plugs. Paint them the same colour as the wall and they will nearly disappear.

It might be reassuring to see some fixings and it would be easy when you move house and take the shelves with you.