GK1":2ndan3s6 said:

I've been making drawers with lapped dovetail fronts and with the back held in a simple housing in each side. The sides extend beyond the back which means there's a bit less space but also that it's unlikely the drawer will be pulled right out. Also I've been making the back less tall so the base gets pinned to the bottom of the back.

Now I've seen various references to having the back dovetailed as well. Is this the more traditional method for good quality work ? Does the entire base fit in a groove or is the back made less tall ? Also is there a way to prevent the drawer from being pulled out - I think I've seen a method where the drawer has to be tilted to slide in and as it's pulled out it meets a stop on the cabinet frame.

I build very traditional drawers: half lap at the front, lapped at the rear, and slips at the sides into a groove at the front ....

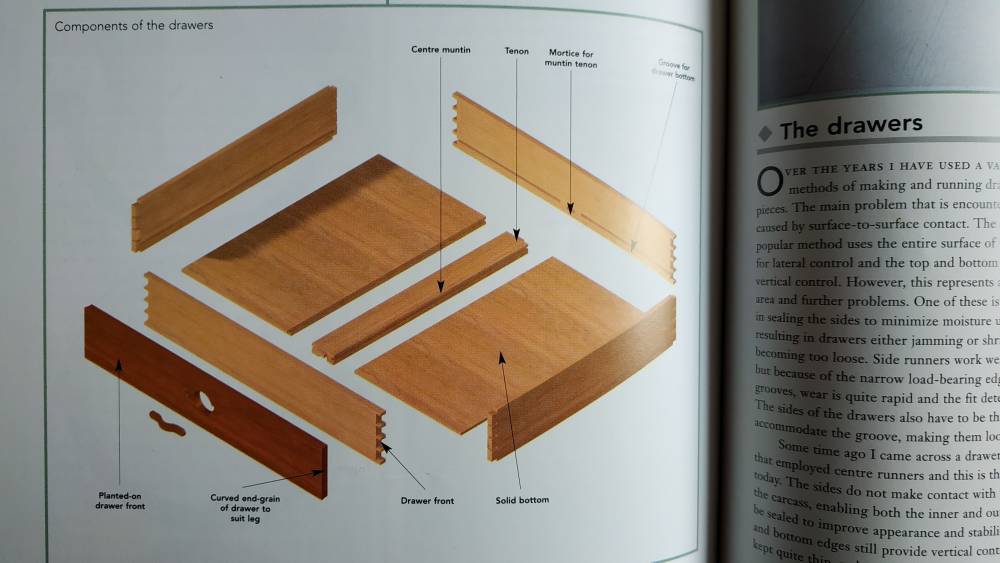

The photo shows the rear of the drawer, sans the drawer bottom. The drawer bottom is solid wood, and the grain runs across from side-to-side for expansion. The drawer sides are are thin, usually 6mm, which is why slips are used (as they are too thin to be grooved). I use quartersawn timber for drawer sides.

Here the drawer bottom is in. The junction between the drawer slip and bottom received a moulding (bead) to disguise the join. The front of the bottom is captured in the groove behind the drawer front ...

The drawer back is lower than the sides, and the ends are chamfered, to make it easier to insert ...

The lapped dovetails at the rear are set with the lowermost dovetail a half tail/pin above the drawer bottom. This drawer is from the Apothecary Chest and, being small, the sides were grooved and not slipped ...

I do use a screw at the rear. This is in an enlarged hole to allow for expansion ...

Lastly, I have begun making an adjustable drawer stop which is attached behind the drawer front. This is my design ...

Regards from Perth

Derek