Thanks Mick, thanks Andy - I think if I ever got around to selling both, the planes also being called Holdfasts might get a bit confusing .... bit of a price difference too.. coincidentally I am designing a plane that has all the best features I can think of and I thought about calling that one "Dreadnought" hoping that no one would confuse it with the file (or the HMS)

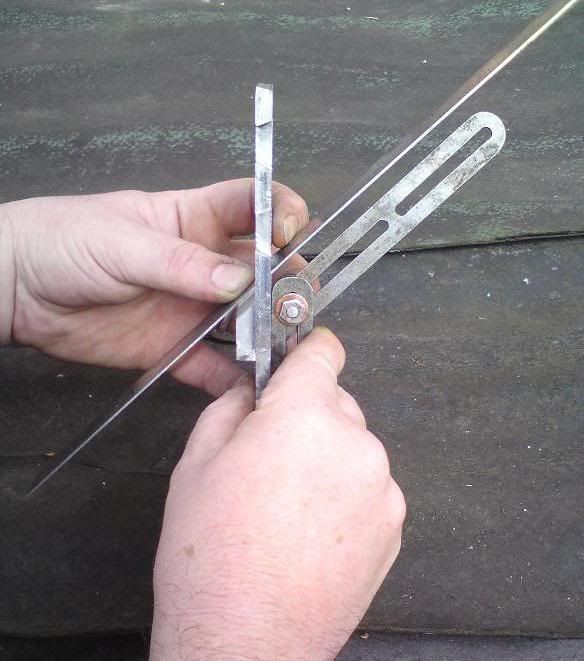

Anyway, here is the vise arrangement I've been using to great effect to see into the corners.

It looks like a design by Mr. G. Bennet, but it works really well in providing a good view of the tiny scribe marks I was trying to file exactly to and not past.

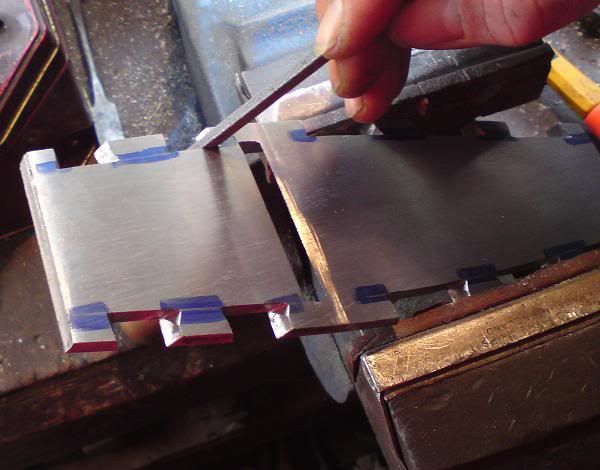

Now here's the first of the you - know - what ...

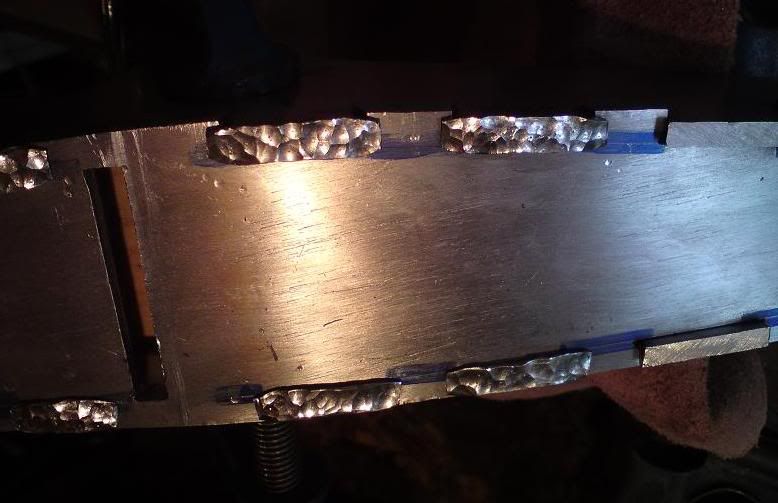

Underside of dovetail peined from the centre to the corner moving steel into the shoulder socket in the pin.

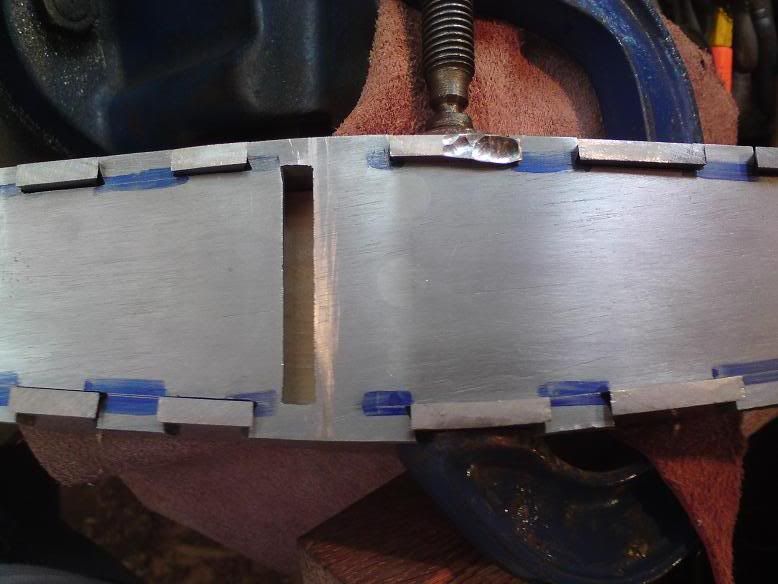

My "punch" - a 1/4lb hammer ball down hit with the 1lb hammer face down. It really helps direct the flow using a punch and less stray hammer marks on the sole too (still some though :roll: )

My high tech clamping system - wooden form inside plane, G cramp on bit being worked, double folded leather over vise jaws. It's crude but it's ok.

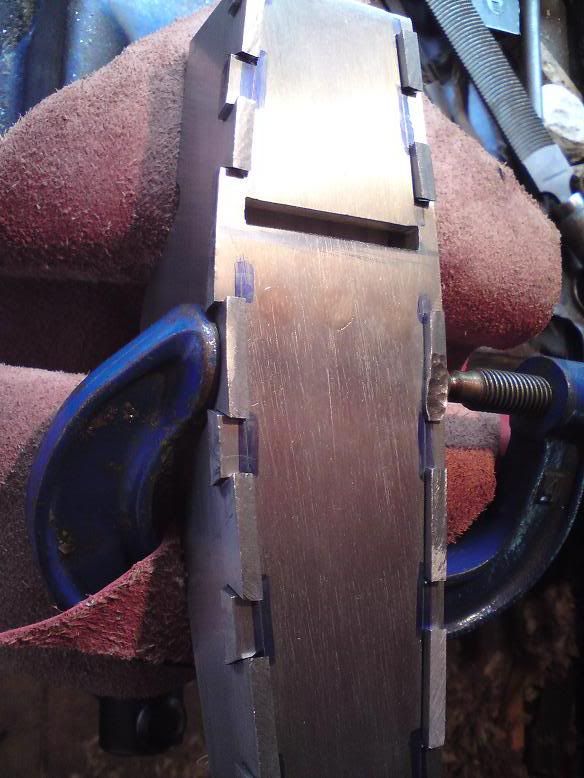

As far as I got a couple oh hours ago. I've since done 'em all but two at the back.

I must say this is much quicker than cutting them. I love it!

)

)