yes, another one.

Been gathering info on this project for a while now, and yesterday, i started playing around with the oak i was going to use for the project.

time to finalise the plan.

so it's got to be fairly big. is there any standard traditional dimensions for dining table ?

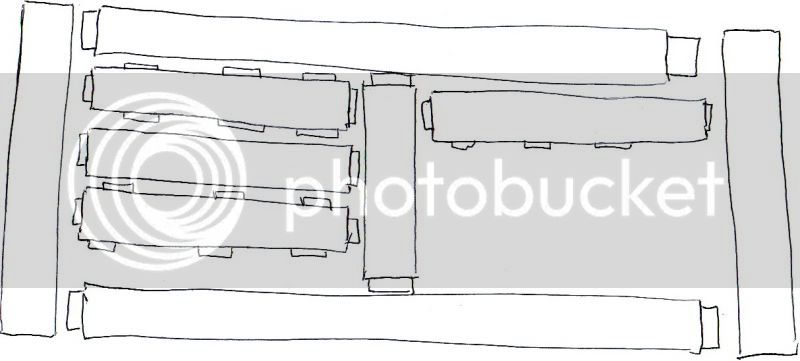

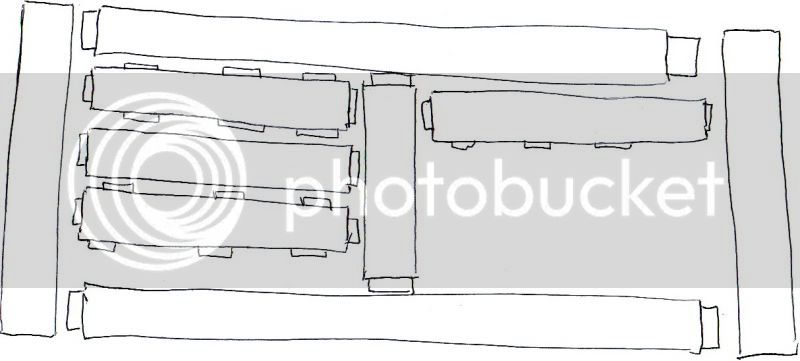

I was going to go for 2100mmx900mm. and here is a quick sketch of how i plan to assemble the top.

Am i way off the mark ?

Been gathering info on this project for a while now, and yesterday, i started playing around with the oak i was going to use for the project.

time to finalise the plan.

so it's got to be fairly big. is there any standard traditional dimensions for dining table ?

I was going to go for 2100mmx900mm. and here is a quick sketch of how i plan to assemble the top.

Am i way off the mark ?