Busy couple of days isolating myself

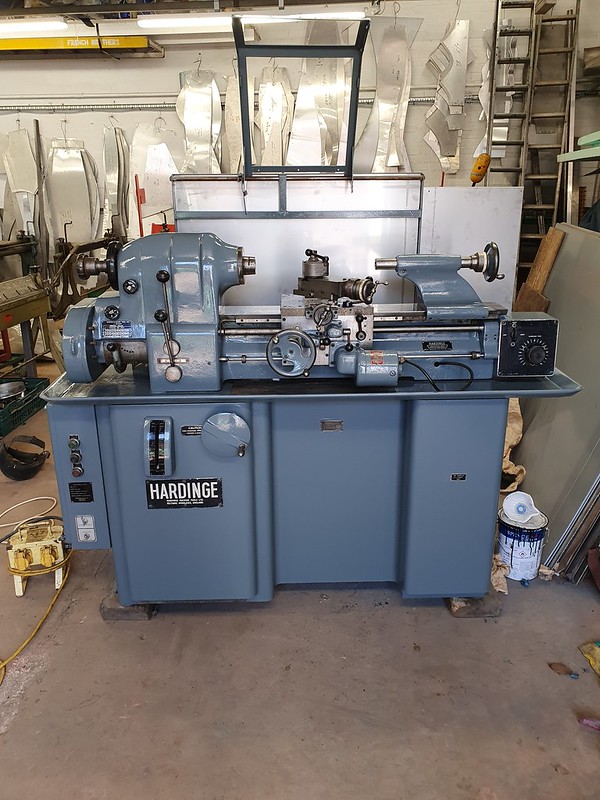

Hardinge 2nd coat done, masking off - very happy with the finish. I'm still in two minds whether to paint the body of the lathe, or just leave it at the cabinet and chip tray. Mainly because I despise paint prep and there's a lot of chips to fill! Hoping to get the gasket cut and the carriage gearbox buttoned back up tomorrow.

2nd coat

2nd coat

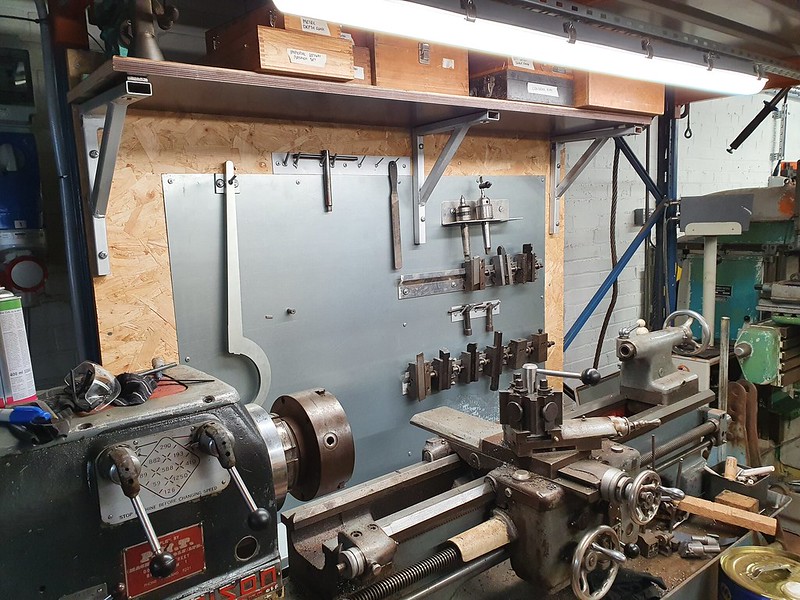

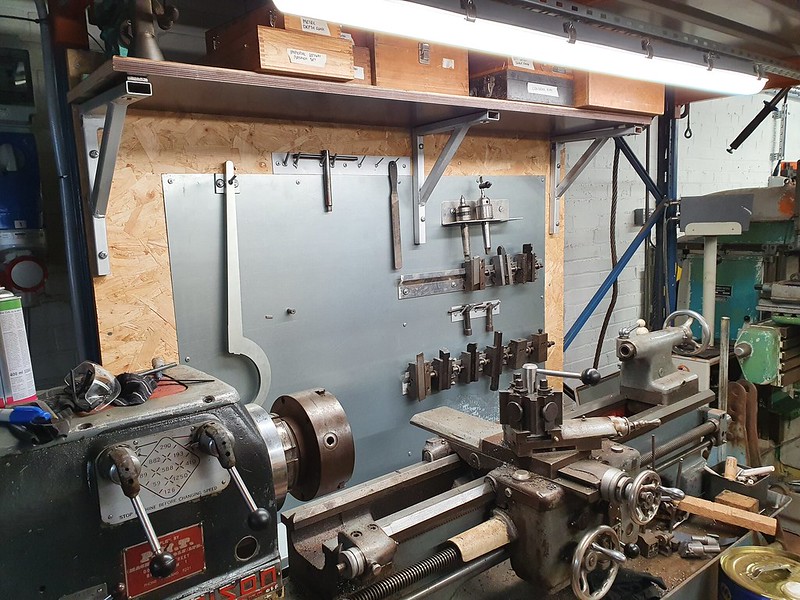

Finished off the splashback - added a shelf for stuff thats rarely used, like the toolpost grinder and hangers for all the chuck keys, file and other bits and bobs that need to be in easy reach.

Splashback finished

Splashback finished

Today I've been sorting the milling machines out - it looked like a bombsite. I got the smaller deckel lifted up onto levelling feet and the power cabinets for both machines moved, then the tooling cabinet for them placed in between. Whole area looks much better now, and more importantly its started to make room for where the Hardinge will eventually go... its like machinery tetris! A toe jack, big levers and rollers - you can do a lot on your own!

A toe jack, big levers and rollers - you can do a lot on your own!

Tidy shop!

Tidy shop!

Hardinge 2nd coat done, masking off - very happy with the finish. I'm still in two minds whether to paint the body of the lathe, or just leave it at the cabinet and chip tray. Mainly because I despise paint prep and there's a lot of chips to fill! Hoping to get the gasket cut and the carriage gearbox buttoned back up tomorrow.

2nd coat

2nd coat Finished off the splashback - added a shelf for stuff thats rarely used, like the toolpost grinder and hangers for all the chuck keys, file and other bits and bobs that need to be in easy reach.

Splashback finished

Splashback finishedToday I've been sorting the milling machines out - it looked like a bombsite. I got the smaller deckel lifted up onto levelling feet and the power cabinets for both machines moved, then the tooling cabinet for them placed in between. Whole area looks much better now, and more importantly its started to make room for where the Hardinge will eventually go... its like machinery tetris!

Tidy shop!

Tidy shop!