AES

Established Member

Blimey, that's a real Aladdin's cave you've got there!

Evenwood saw

Evenwood saw  Evenwood rear panel

Evenwood rear panel  Evenwood painted

Evenwood painted  Broken casting

Broken casting  Sandblasted

Sandblasted Tig brazing

Tig brazing Brazed!

Brazed! Success

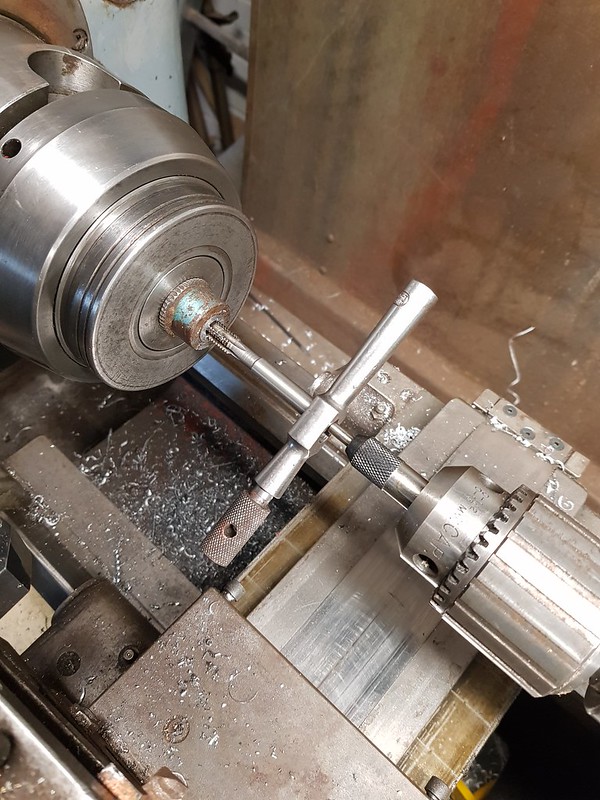

Success Turned pin

Turned pin Next part

Next part TFrench":3d4v02rs said:One word: Farmers.

Tapping

Tapping Both ends tapped

Both ends tapped Back together

Back together Knurling

Knurling Milling flat

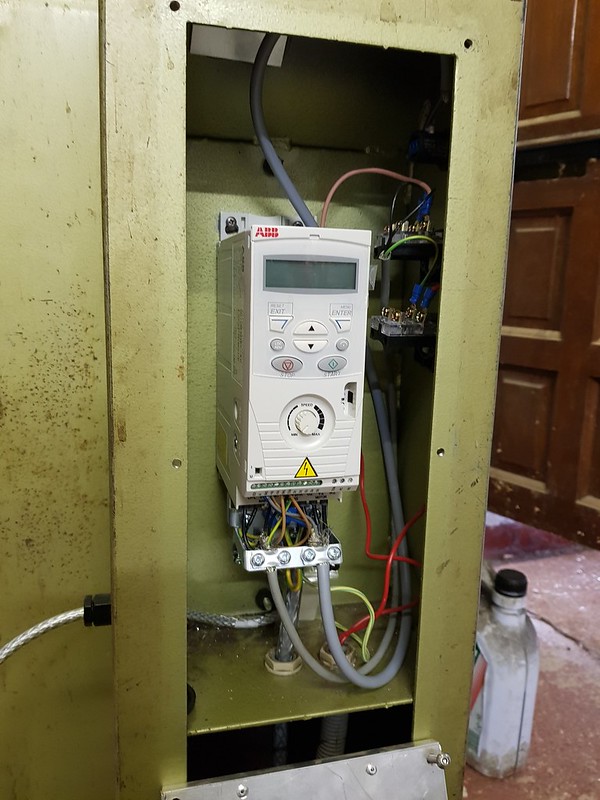

Milling flat  Inverter

Inverter Tool rack

Tool rack

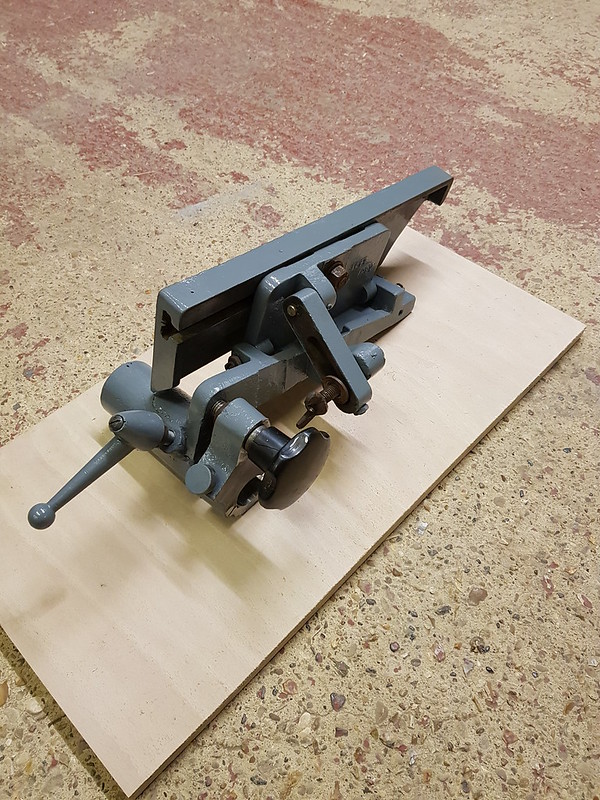

Startrite mitre guide

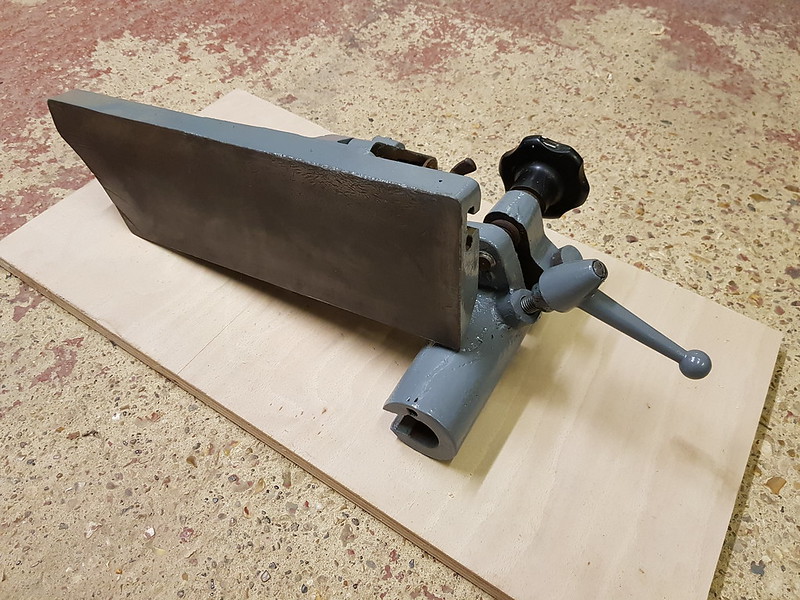

Startrite mitre guide Finished fence

Finished fence  Finished fence

Finished fenceEnter your email address to join: