Derek Cohen (Perth Oz)

Established Member

The design of the chair needs to compliment the bentwood chairs we have, which are original and early 1900s. The table is to be replaced with a longer, wider one.

This table is over 200 years old, and has great sentimental value. It is built of Yellow Wood (top) and Stinkwood (legs). We bought this after getting married. Now, 42 years later, Lynndy wants a larger table.

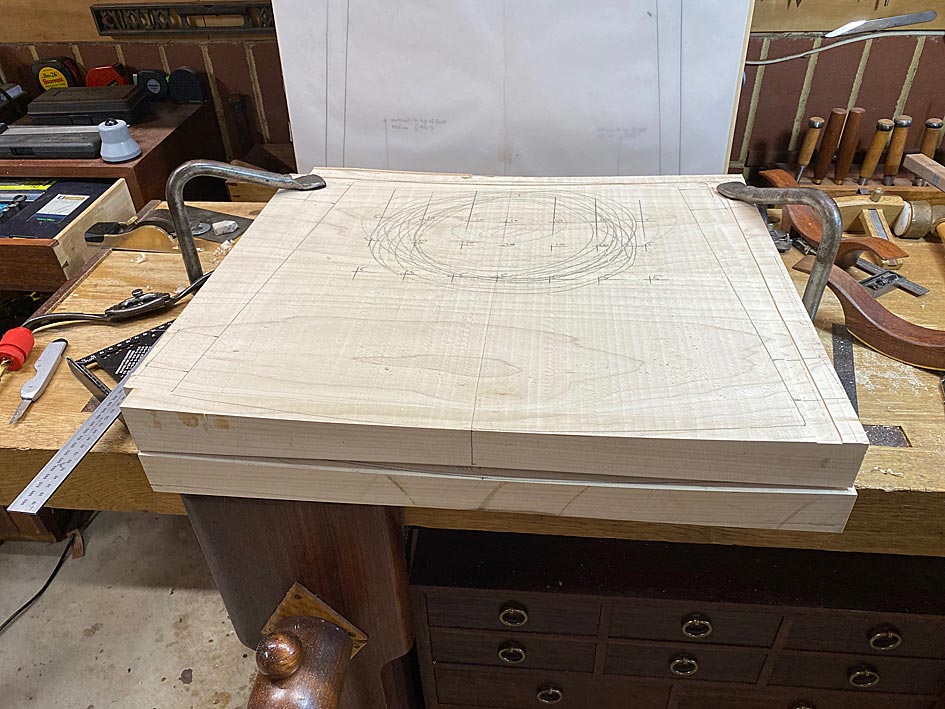

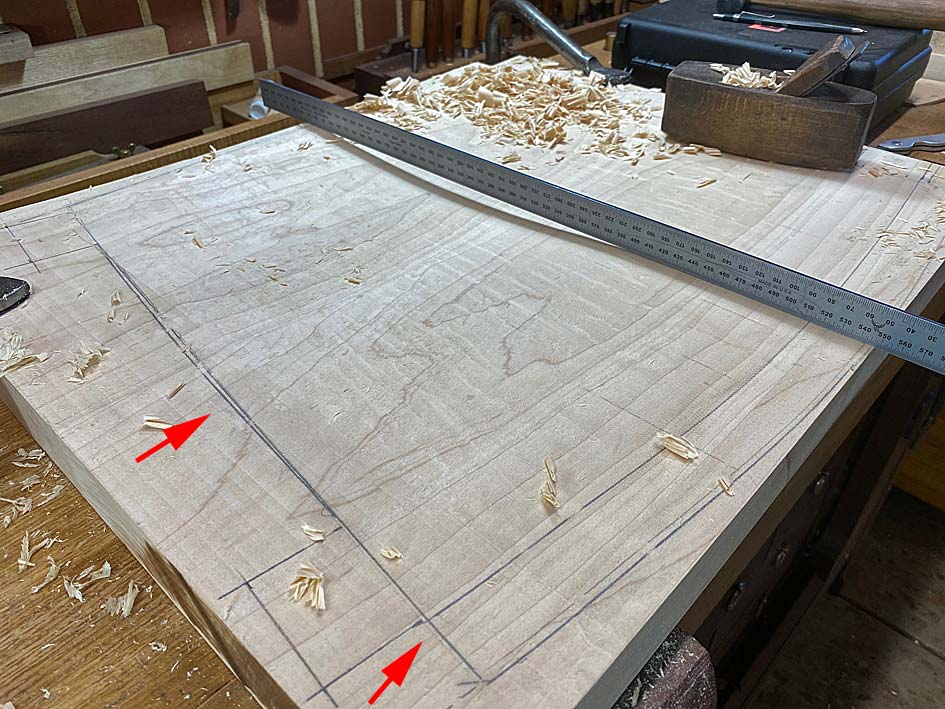

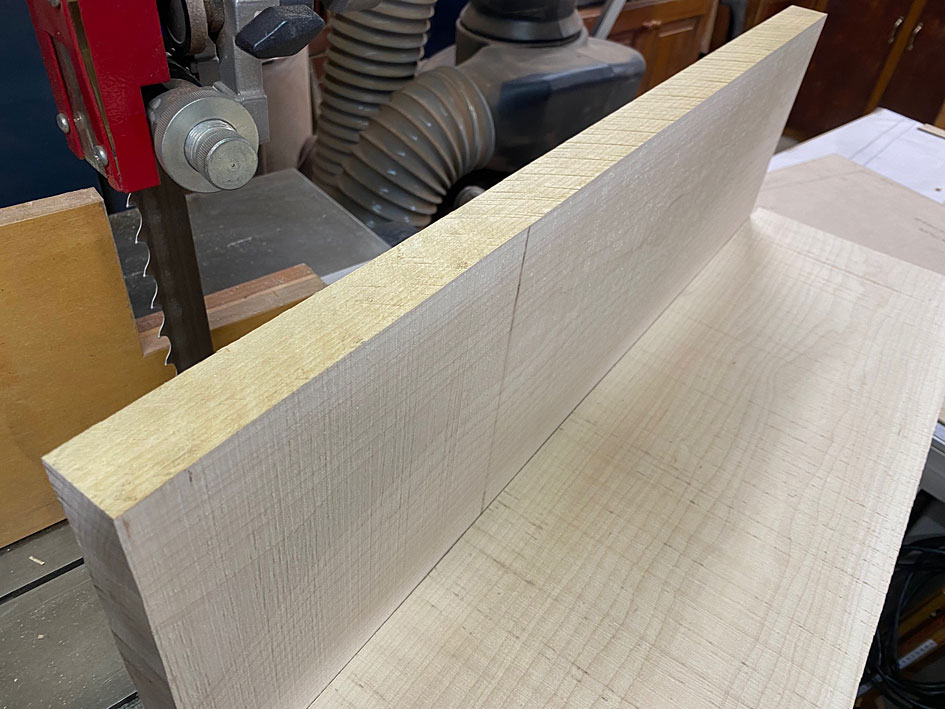

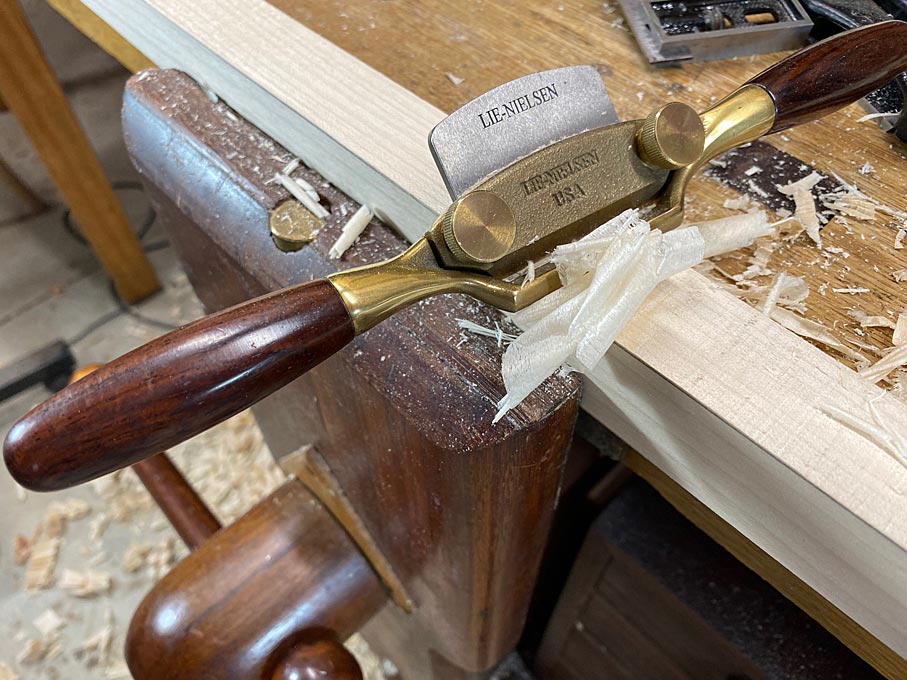

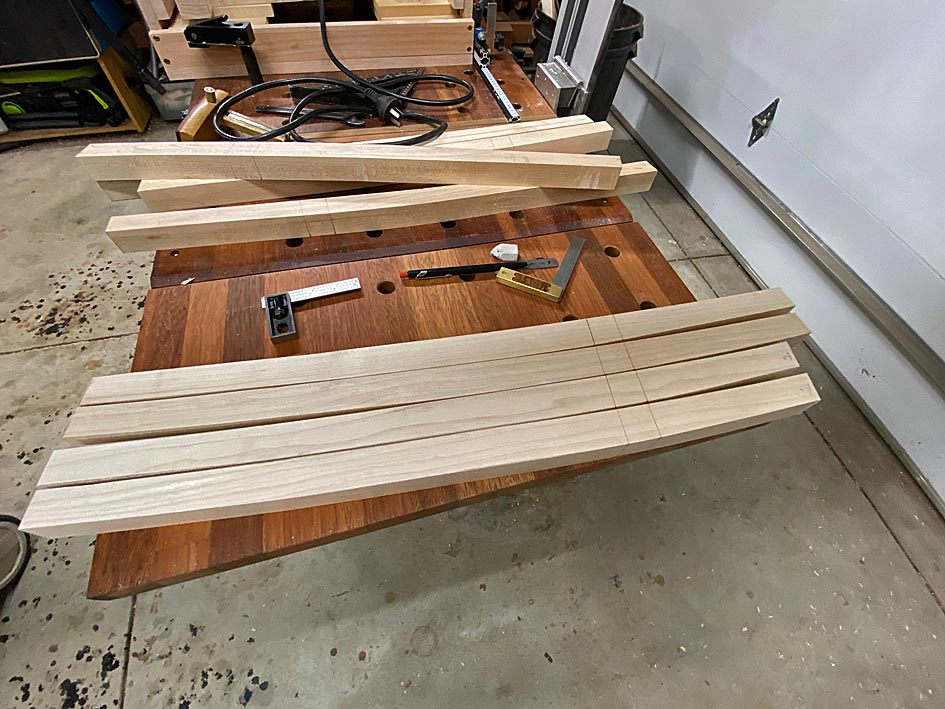

The plan is a table with a top and skirts in Rock Maple and round, parallel legs in Jarrah - very Mid Century modern. The aim is to blend two modern Mid Century carvers in Rock Maple with the bentwood chairs. Consequently, a lighter look for the carvers is needed.

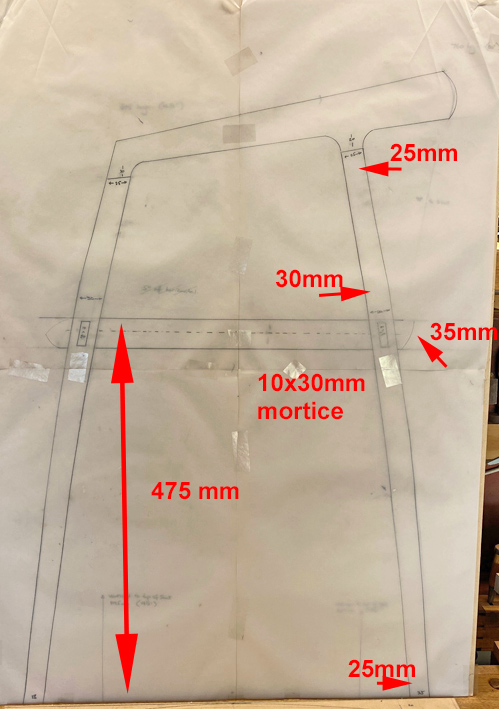

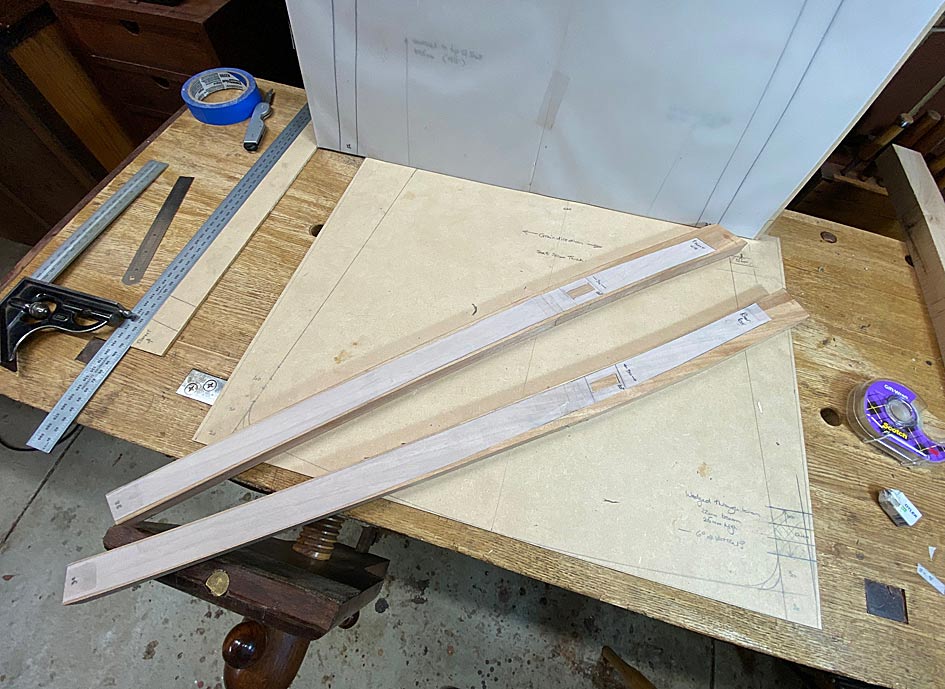

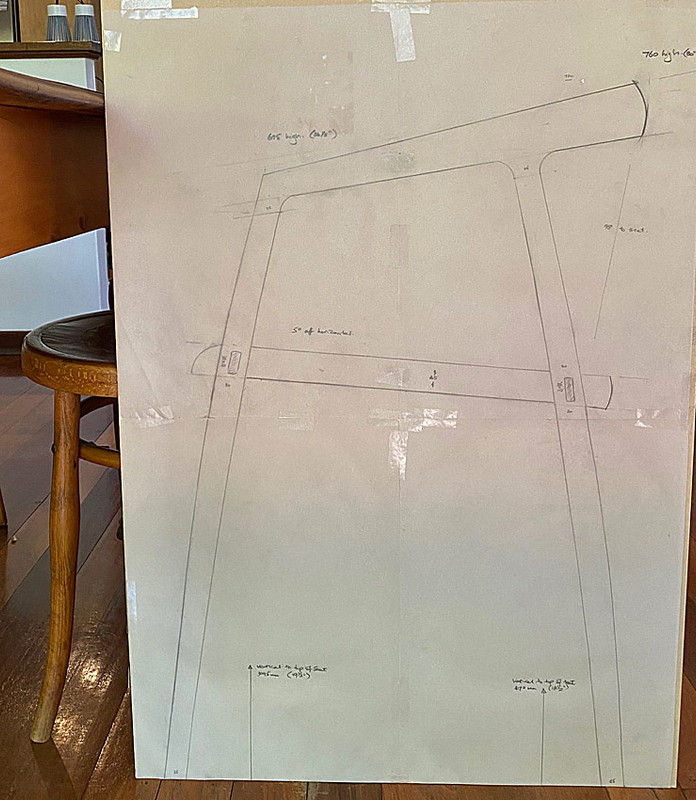

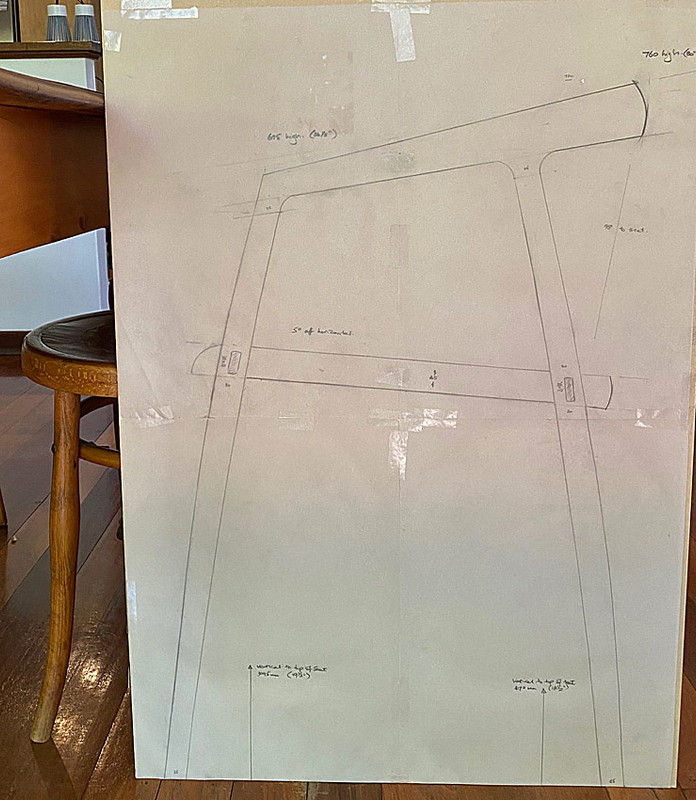

Here is the design.

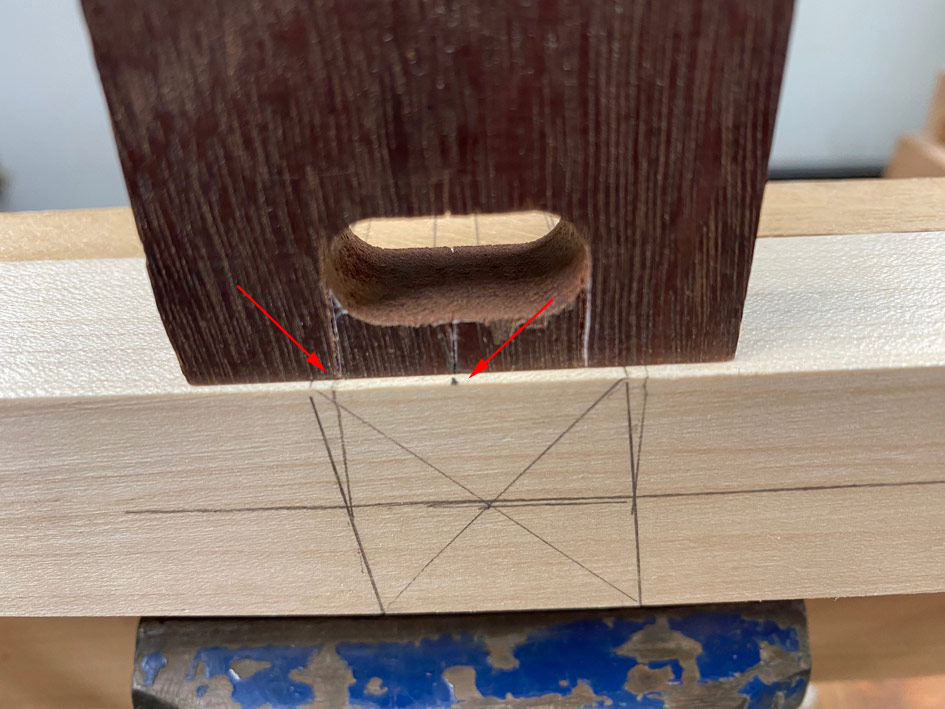

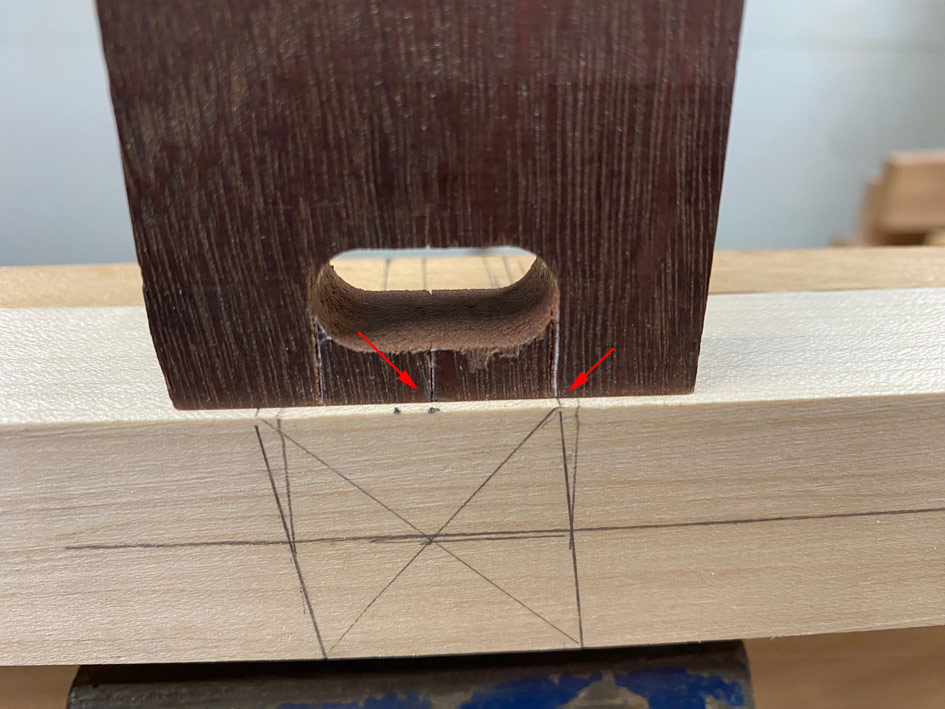

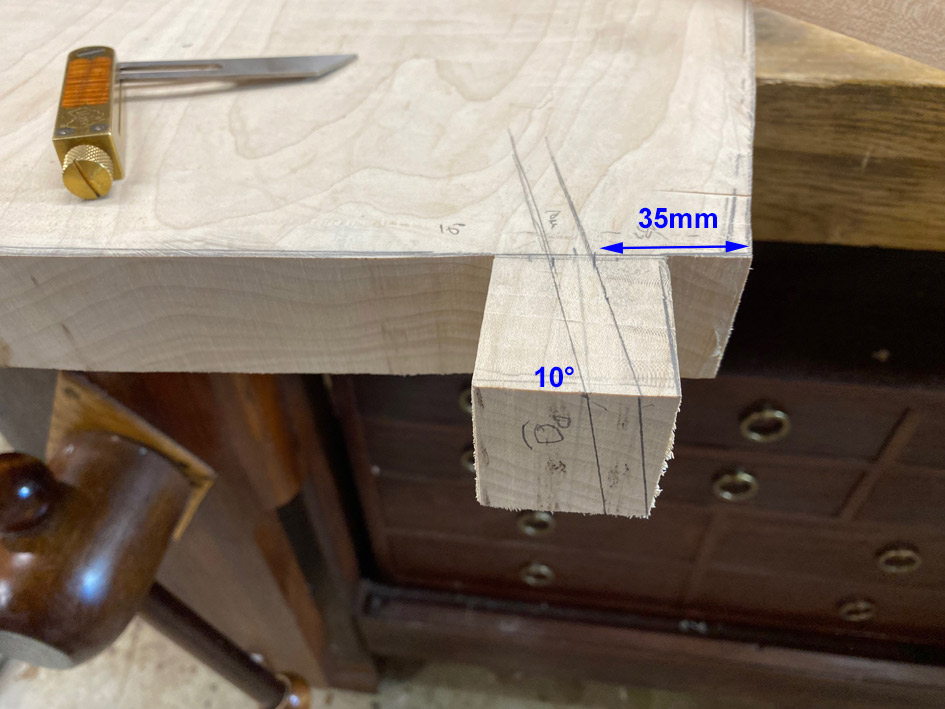

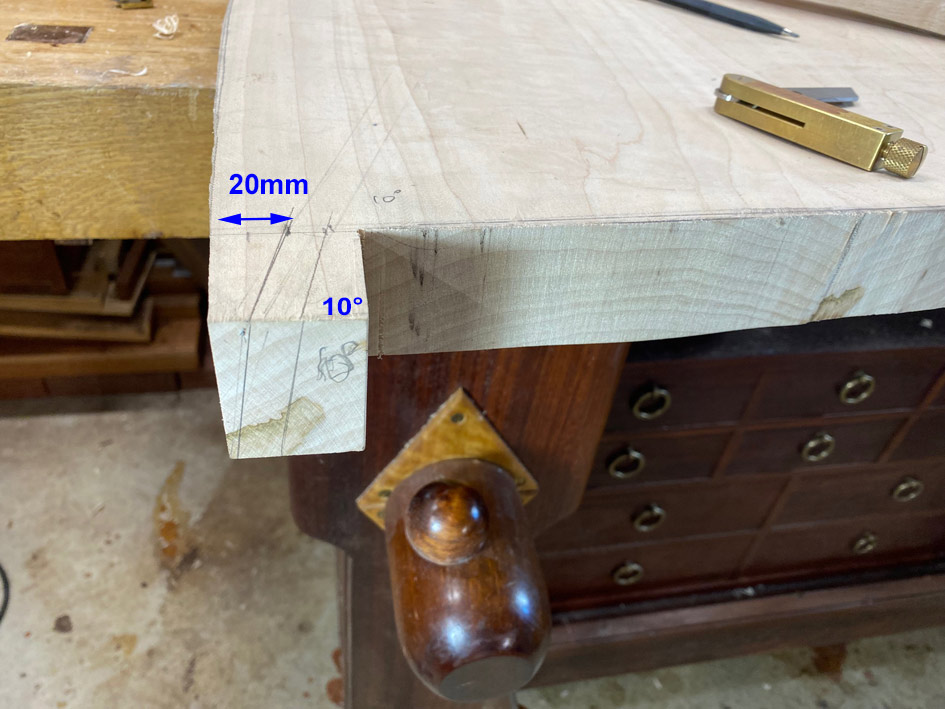

The legs are curved and round, with 25mm top and bottom, and 32mm around the seat area to accommodate the joinery. The 35mm thick seat will be attached with mortice-and-tenons (not sure yet whether integral or loose tenons). These will be 25x10mm.

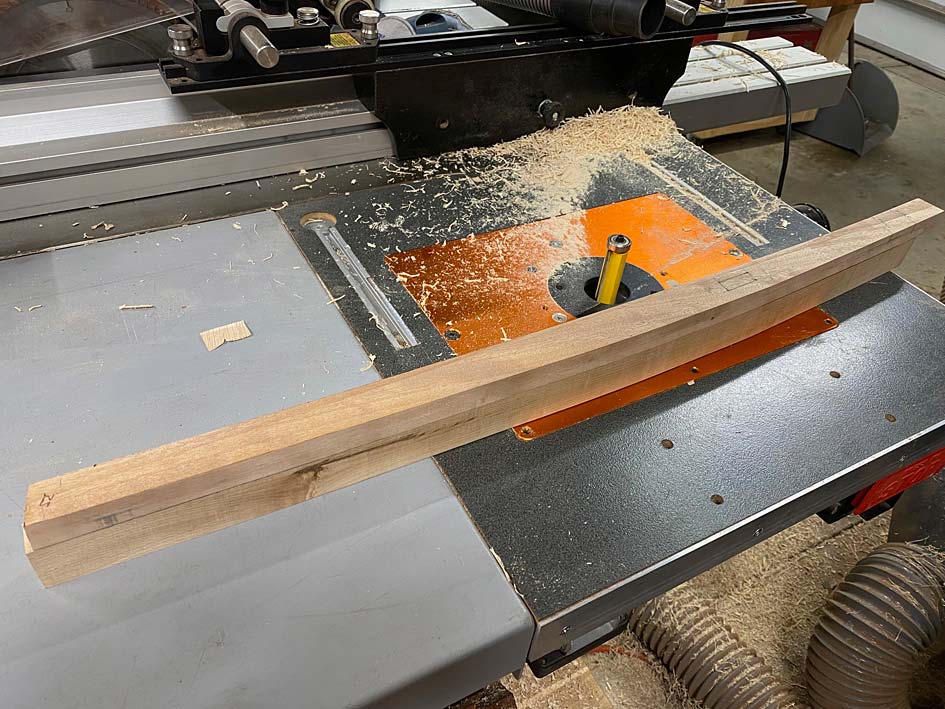

The curve in the legs is a desired feature to soften the look and also link with the bentwood chairs. The complication, in shaping, is that there is a taper and a curve.

The height of the top section has been reduced significantly. The design ...

Then there are finer details being worked out, such as the curve at the rear of the backrest and seat to link with the roundness of the bentwood chairs. The transition from the legs to the arm rest is borrowed from Hans Wegner and used when I build his The Chair.

Details of importance: the seat angled at 5-degrees off horizontal, and the backrest is 95-degrees to the seat. The centre of the seat is the same height as the benchwood chairs.

The plan shape for the arm- and back rest will come later.

Thoughts?

Regards from Perth

Derek

This table is over 200 years old, and has great sentimental value. It is built of Yellow Wood (top) and Stinkwood (legs). We bought this after getting married. Now, 42 years later, Lynndy wants a larger table.

The plan is a table with a top and skirts in Rock Maple and round, parallel legs in Jarrah - very Mid Century modern. The aim is to blend two modern Mid Century carvers in Rock Maple with the bentwood chairs. Consequently, a lighter look for the carvers is needed.

Here is the design.

The legs are curved and round, with 25mm top and bottom, and 32mm around the seat area to accommodate the joinery. The 35mm thick seat will be attached with mortice-and-tenons (not sure yet whether integral or loose tenons). These will be 25x10mm.

The curve in the legs is a desired feature to soften the look and also link with the bentwood chairs. The complication, in shaping, is that there is a taper and a curve.

The height of the top section has been reduced significantly. The design ...

Then there are finer details being worked out, such as the curve at the rear of the backrest and seat to link with the roundness of the bentwood chairs. The transition from the legs to the arm rest is borrowed from Hans Wegner and used when I build his The Chair.

Details of importance: the seat angled at 5-degrees off horizontal, and the backrest is 95-degrees to the seat. The centre of the seat is the same height as the benchwood chairs.

The plan shape for the arm- and back rest will come later.

Thoughts?

Regards from Perth

Derek