custard":17ig2x4k said:

The issue I'm focussed on is your claim that shellac provides "a brilliant barrier to water vapour", if a newcomer to woodworking buys into such nonsense they may think there's no need to design their furniture to accommodate wood movement.

That's a bit of a stretch, I didn't say you could do anything like that and had no intention of implying it. As I already stated, I didn't mean to imply it's a complete seal and if the OP had required clarification I would have given it.

I thought initially you were hung up on the terminology I used in an off-the-cuff comment more than anything, making this somewhat of a semantics debate, but your last sentence shows otherwise.

custard":17ig2x4k said:

Anyone in that position needs to understand that a coat of shellac has minimal effect on water vapour transmission and therefore minimal effect on timber movement.

I think if you read on you'll see that Flexner would not agree that this is true.

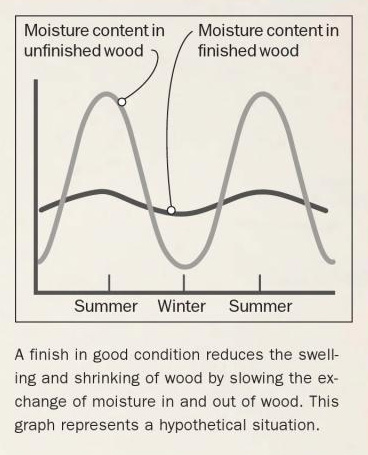

Film finishes slow water-vapour transfer into and out of the wood and, obviously, how much is related to the film thickness.

I think you don't believe this includes shellac, but Flexner makes reference to finish in the broadest terms slowing water-vapour transfer in an article written in 2006 which he repeats (I think verbatim) in two of his later books, from 2010 and '11:

- No matter how a finish deteriorates, the end result is increased moisture exchange in the wood...

...

Furniture requires a finish in good shape to protect the wood from moisture exchange and to make the wood look nice.

...

The easiest way to keep moisture exchange to a minimum is to keep the finish in good shape.

That's pretty clear, and further I think the accompanying graph plainly shows he believes the effect to be significant:

So I feel comfortable with my later statement that a well-built shellac coat, as you'd expect in French polishing,

does provide significant protection to that face of a board