Hi,

I have fitted some basic kitchen unit carcases but want to make the doors myself. I am really trying to keep costs down have a really limited budget and don't have a workshop.

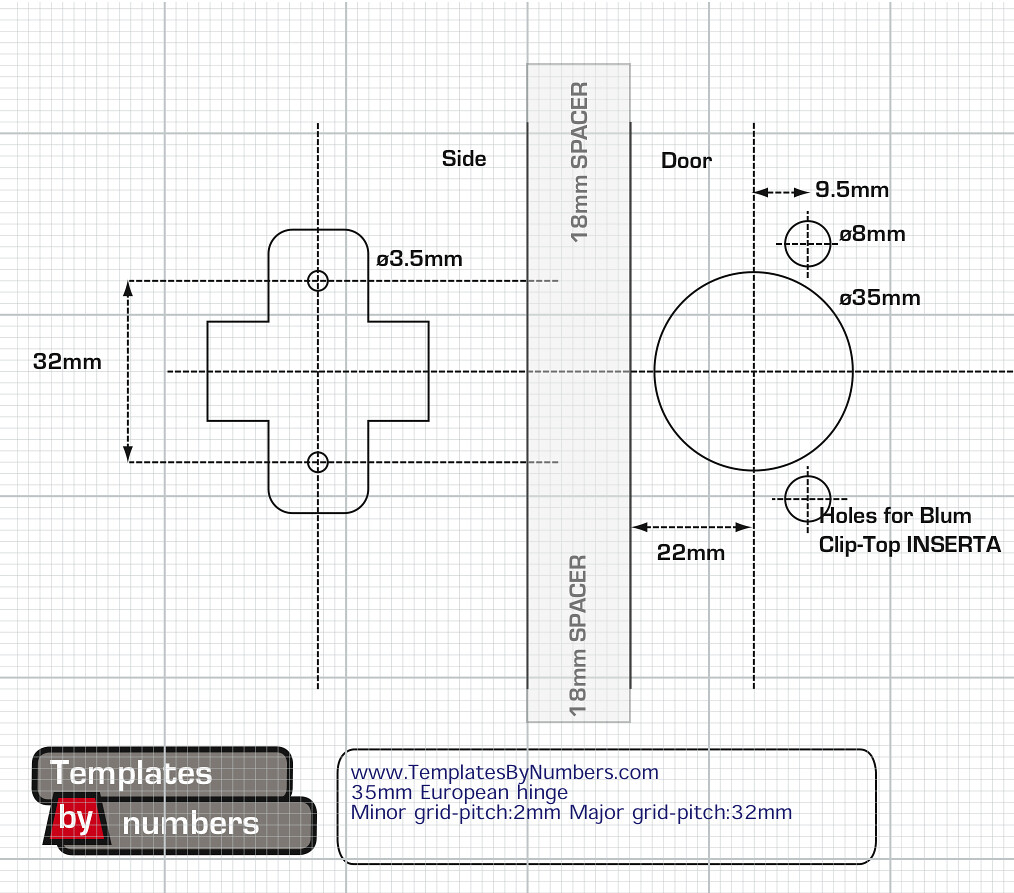

My first question regards euro hinges. Is it possible to use a forstner bit successfully with just a hand held drill?

I have seen a 'Rockler JIG IT Drill Guide' (£45 from US I think) but it seems a bit of an expense as I will probably not use it again after completeing the kitchen. Does anyone know of an alternative that you can buy in the UK?

Axminster sell a 'Universal Hinge Jig' for a router (and I own a router).....any thoughts on this.....has anyone used it?

For the doors I was thinking of constucting a frame from 1x3" using pocket hole joinery (Possibly the kregg R3?). Then run around the middle of the frame with a rebate bit on the router and drop a panel in (not sure what to use for the panel yet). Then paint.

Any advice or pointers would be greatly appreciated. Sorry i couldn't post any links but Idon't have permision.....its my first post here....

Oh, one last thing. Is there a maximum depth of cupbaord door that a euro hinge will work with? The bought doors for the carcases I fitted are 18mm.

Phew

I have fitted some basic kitchen unit carcases but want to make the doors myself. I am really trying to keep costs down have a really limited budget and don't have a workshop.

My first question regards euro hinges. Is it possible to use a forstner bit successfully with just a hand held drill?

I have seen a 'Rockler JIG IT Drill Guide' (£45 from US I think) but it seems a bit of an expense as I will probably not use it again after completeing the kitchen. Does anyone know of an alternative that you can buy in the UK?

Axminster sell a 'Universal Hinge Jig' for a router (and I own a router).....any thoughts on this.....has anyone used it?

For the doors I was thinking of constucting a frame from 1x3" using pocket hole joinery (Possibly the kregg R3?). Then run around the middle of the frame with a rebate bit on the router and drop a panel in (not sure what to use for the panel yet). Then paint.

Any advice or pointers would be greatly appreciated. Sorry i couldn't post any links but Idon't have permision.....its my first post here....

Oh, one last thing. Is there a maximum depth of cupbaord door that a euro hinge will work with? The bought doors for the carcases I fitted are 18mm.

Phew