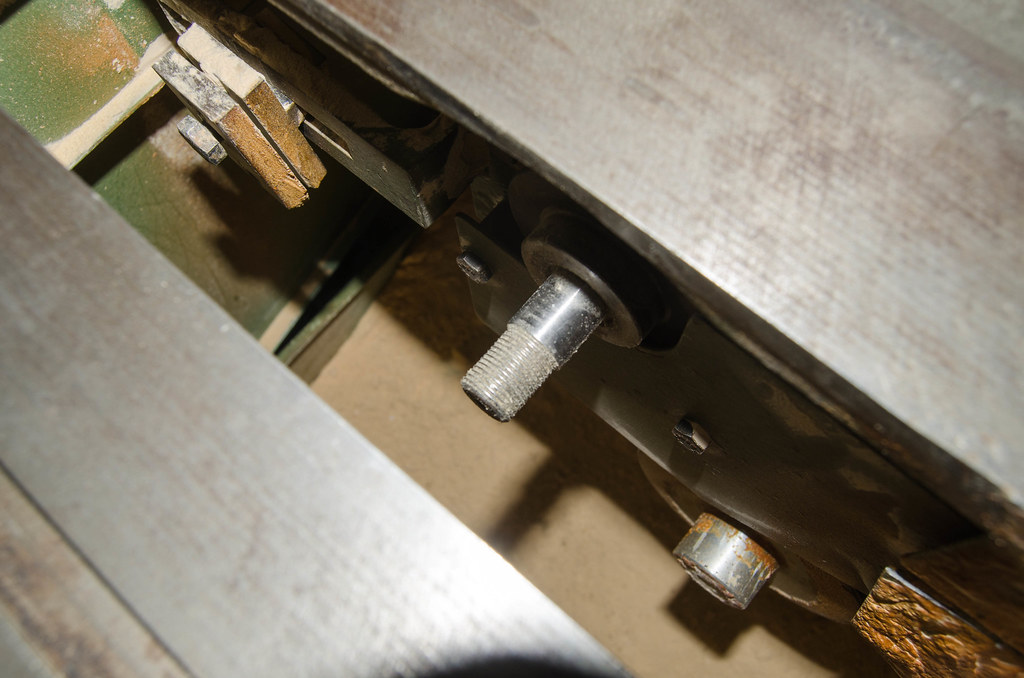

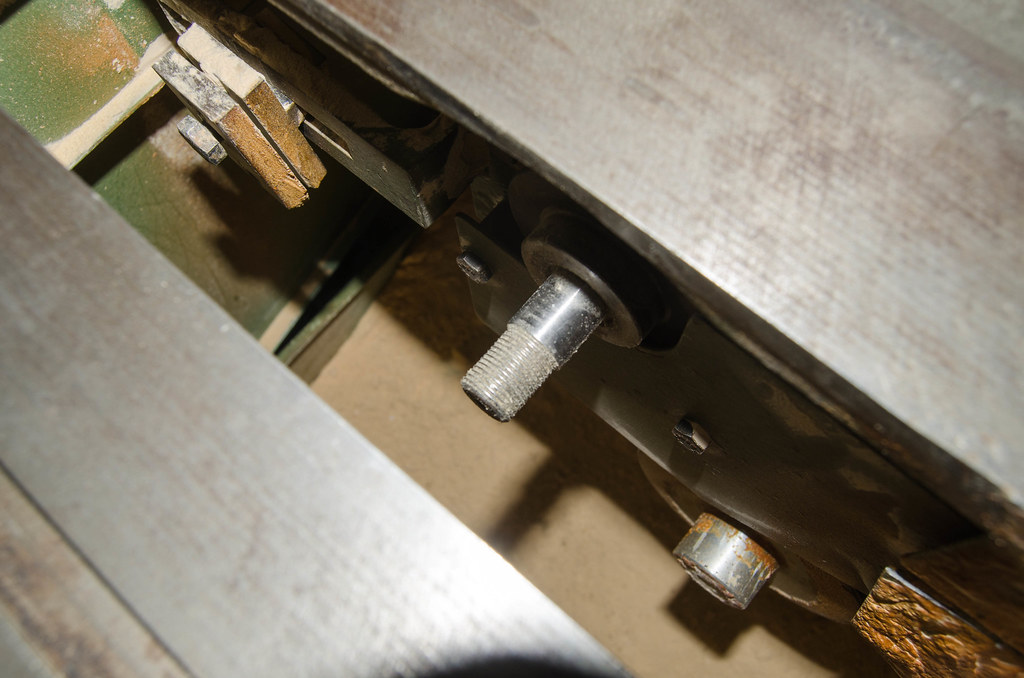

I read something in an old post here about making a sort of slip-over adapter for a smaller arbor so you'd be able to mount 30mm blades without using inserts. I got a 20mm arbor and while fiddling with the inserts isn't that bad I wonder if the idea is practical if I wanted to get a longer arbor though? I might as well turn it into a 30mm one then too.

What I am thinking is a round 30mm piece with internal threads that simply screws onto the current arbor, this is then the new bigger arbor. Sounds pretty simple to me. But I am not sure if that would work or not, maybe I am overlooking something? Maybe there's a risk of the whole arbor coming loose (perhaps it's no bigger than the risk of the nut coming loose during regular operation) or something else I've overlooked?

Is there perhaps someone who does this kind of job routinely or would I have to start looking for local machinists?

What I am thinking is a round 30mm piece with internal threads that simply screws onto the current arbor, this is then the new bigger arbor. Sounds pretty simple to me. But I am not sure if that would work or not, maybe I am overlooking something? Maybe there's a risk of the whole arbor coming loose (perhaps it's no bigger than the risk of the nut coming loose during regular operation) or something else I've overlooked?

Is there perhaps someone who does this kind of job routinely or would I have to start looking for local machinists?