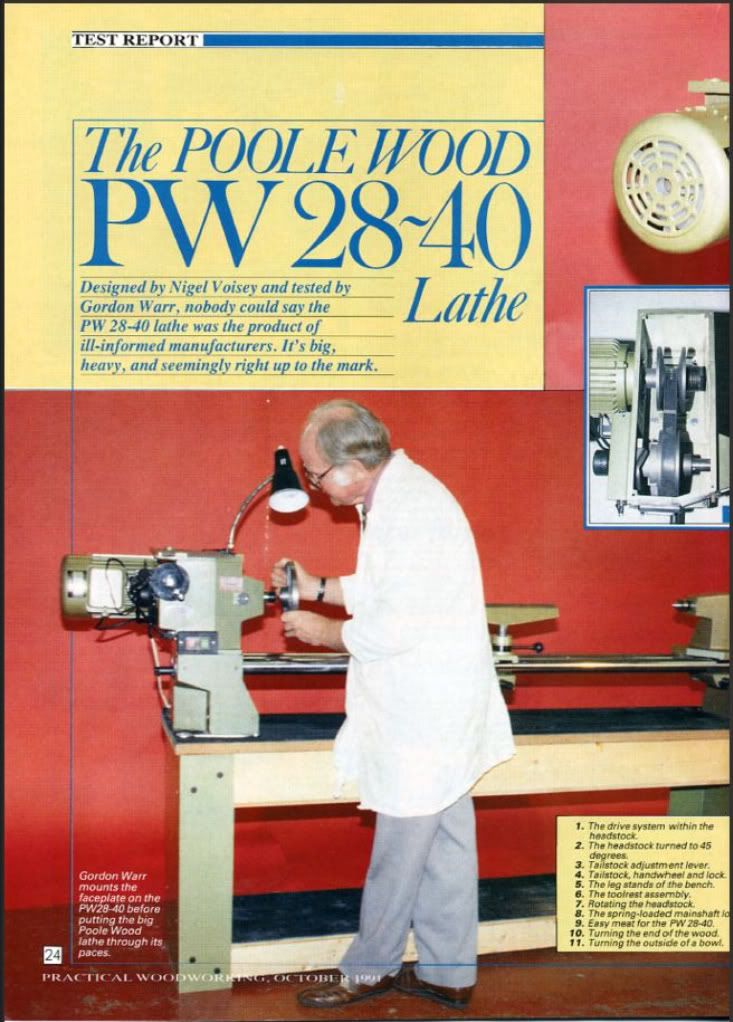

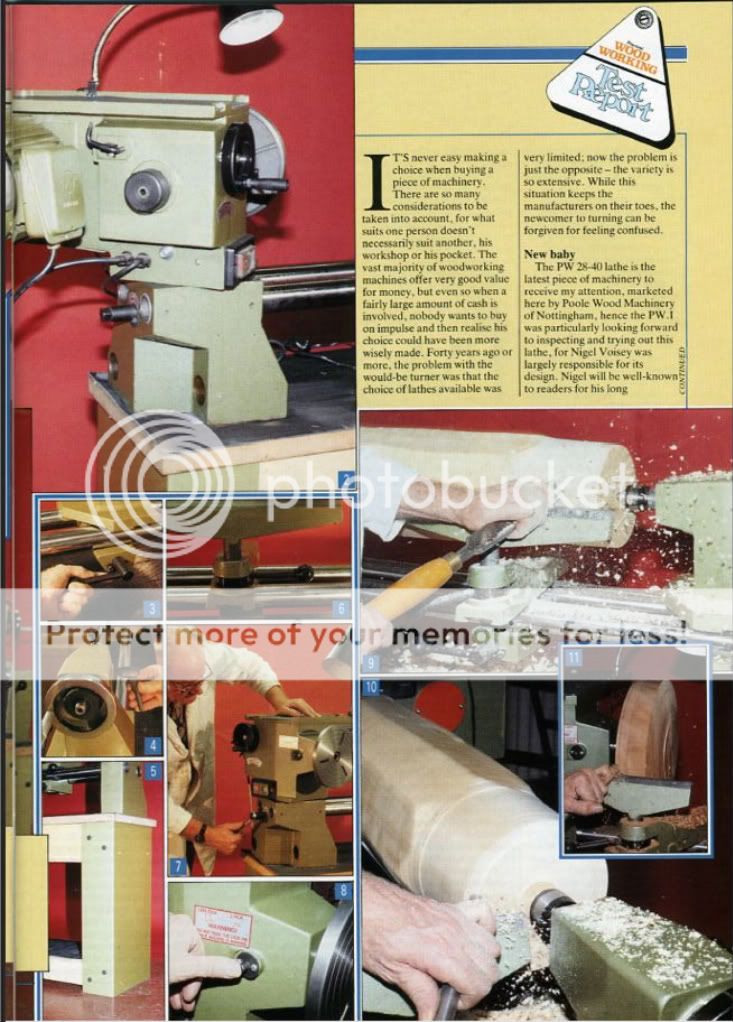

I have both Types, the old mechanical drive version and the later variable (3ph invertor) machine.

The electronic is my user, it's still heavily built but more refined (castings are slimmer and tool rest banjos etc are slimmed down) than the Mechanical drive version.

I would not choose the mechanical one over the later 3ph motor versions given the choice as the latter gives you a reversing capability and quieter drive chain.

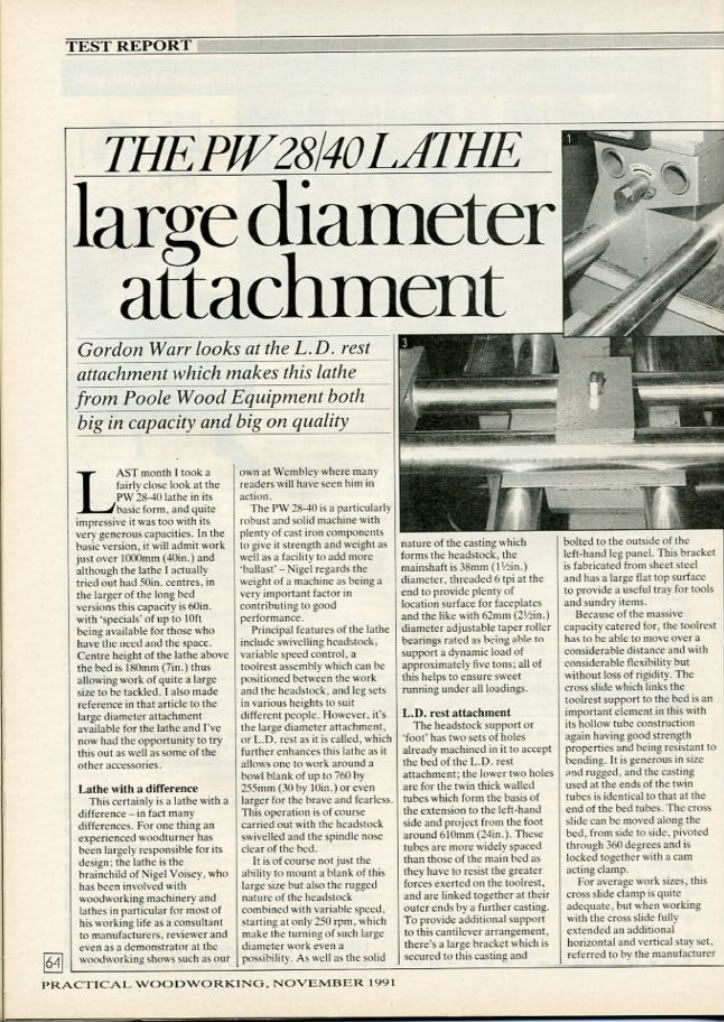

But if you've got the room and the strength to handle the mechanical version it's a big heavy duty beast if available for the right price, the tubular bed bars are not up to the same rigidity standard as the bulky design of the head stock assembly, like that you would get with a cast bed, in either machine, but I find them adequate for anything I throw at it.

My Mechanical drive version is awaiting room in the shed to set it up as a dedicated large diameter Bowl/Platter machine. The parts between the two are not generally interchangable due to differing bar spacings and centre height. The Mechanical drive version has a very large (physical size) 6pole slow speed motor. If two people can lift the lathe head and motor to waist height with comfort then they are both somewhat stronger than me.

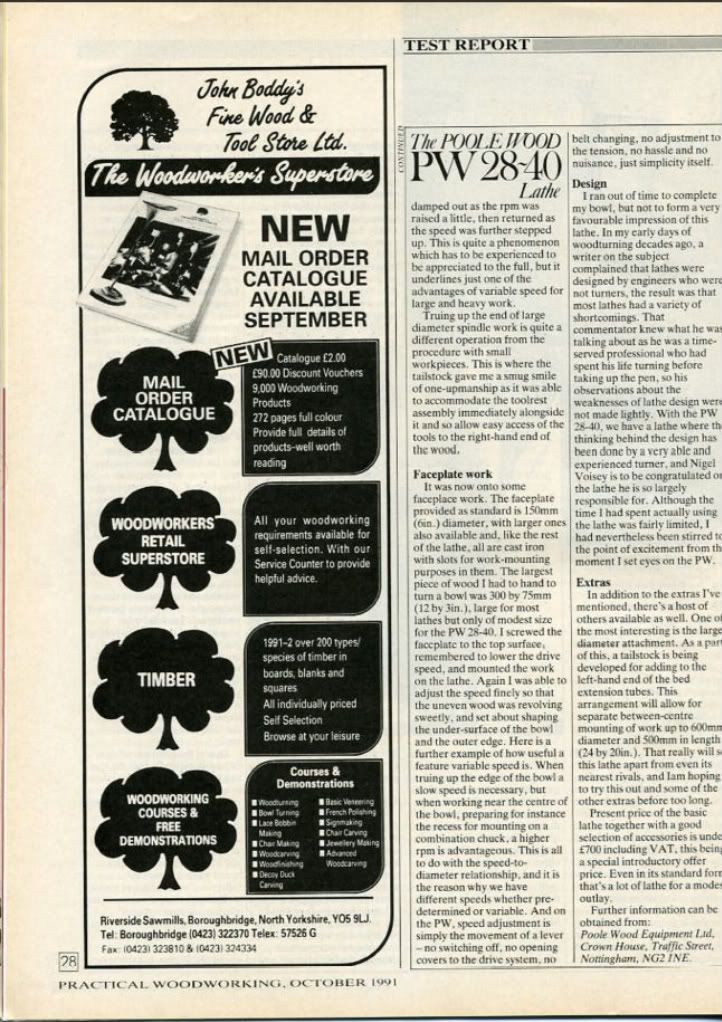

Oh, and one major consideration, if the machine you are looking at is offered with matching Chucks and faceplates take them, the Poolwood spindles are not a current standard, in fact the chuck registers vary between the earlier and later models of the 2840 so unless you have the means of making adaptors or spacers you may have difficulty getting a chuck to fit. The threads are 1-1/2" X 6TPI but the headstock casting clearance and chuck register collar differ from the current norm for 1-1/2" spindles.

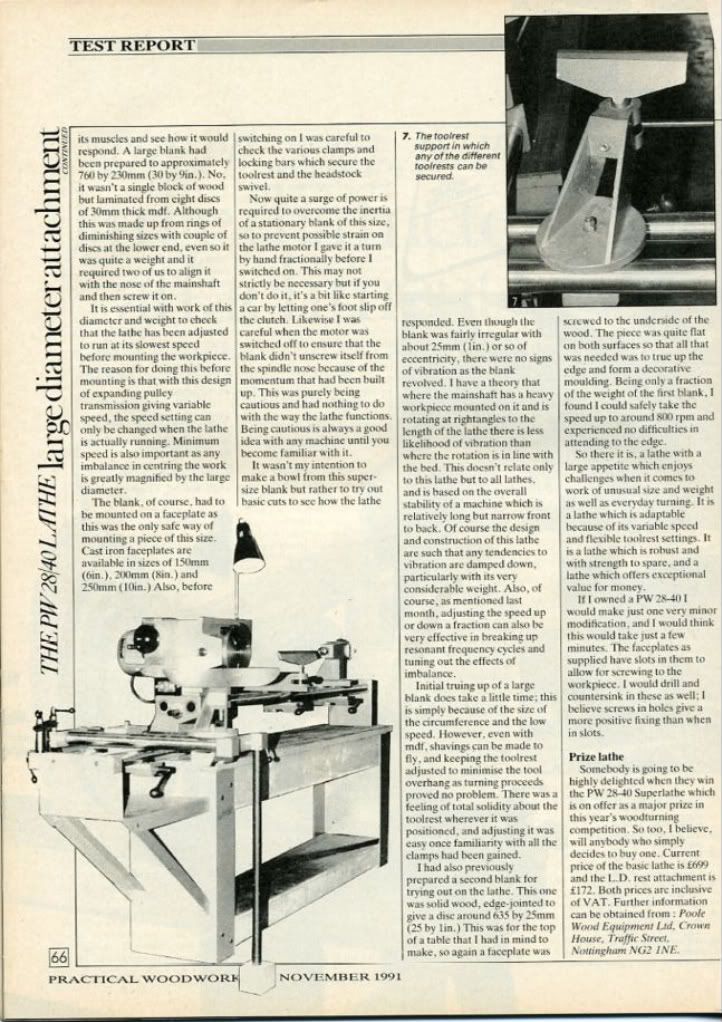

See this OLD Axminster chart (TO2P) But this is not the whole story because the two machines I have are different.

![Poolewood1[1].jpg Poolewood1[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attach/44/44737-Poolewood1-1-.jpg)

![Poolewood2[1].jpg Poolewood2[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attach/44/44738-Poolewood2-1-.jpg)

![Poolewood3[1].jpg Poolewood3[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attach/44/44739-Poolewood3-1-.jpg)

![Poolewood4[1].jpg Poolewood4[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attach/44/44740-Poolewood4-1-.jpg)

![Poolewood5[1].jpg Poolewood5[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attach/44/44741-Poolewood5-1-.jpg)

![Poolewood6[1].jpg Poolewood6[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attach/44/44742-Poolewood6-1-.jpg)

![poolewood7[1].jpg poolewood7[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attach/44/44743-poolewood7-1-.jpg)

![Poolewood8[1].jpg Poolewood8[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attach/44/44744-Poolewood8-1-.jpg)

![Poolewood1[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attachments/44/44737-983df89849ee861d06edc8d0c046fc0e.jpg)

![Poolewood2[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attachments/44/44738-7236d0aa811ff9109cdd1c0a8f4e6e97.jpg)

![Poolewood3[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attachments/44/44739-9d300546e4918f873a64bde86cc92a13.jpg)

![Poolewood4[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attachments/44/44740-48ab85699fc4002ddf0a63d52216e906.jpg)

![Poolewood5[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attachments/44/44741-8a70d14b60c2166e7432978574c8fb0b.jpg)

![Poolewood6[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attachments/44/44742-1632bfea7a245c38c72b8ff701c5df0d.jpg)

![poolewood7[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attachments/44/44743-c3c4a7a9878051a5a840536df1301c96.jpg)

![Poolewood8[1].jpg](https://cdn.imagearchive.com/ukworkshop/data/attachments/44/44744-5090769641a3edd146794c1a8e92fc06.jpg)