santiniuk

Established Member

Hi,

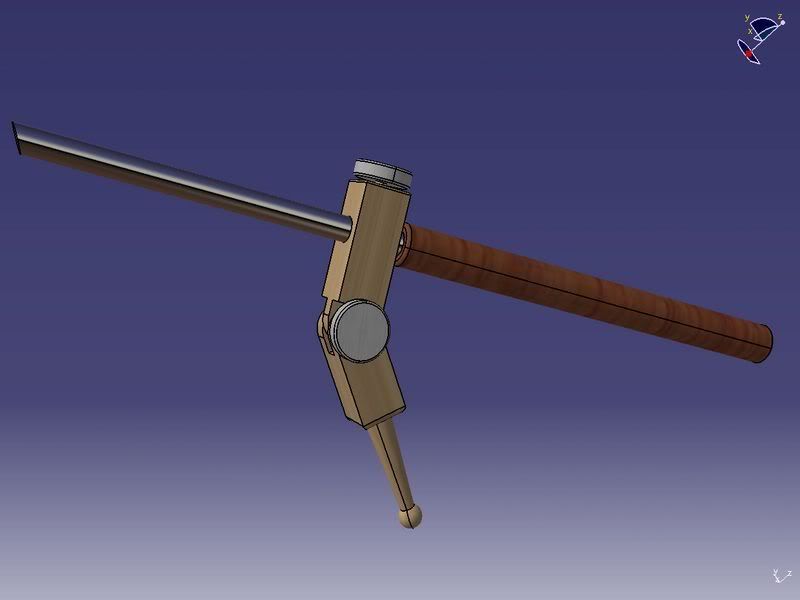

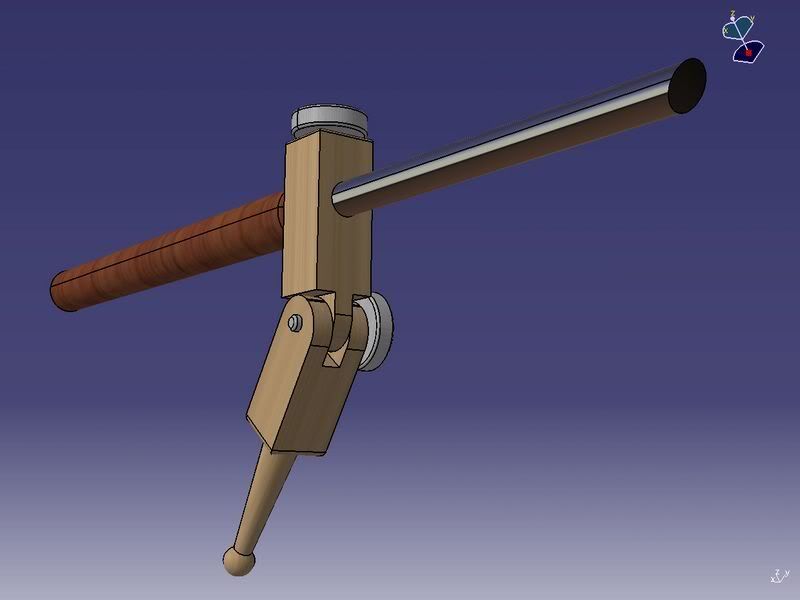

Continuing from a previous thread I thought I'd post an idea that I hope would be suitable for anyone to make.

Again it uses some of the fundamental ideas that Chas posted but really is as easy as could be to make. (I think!)

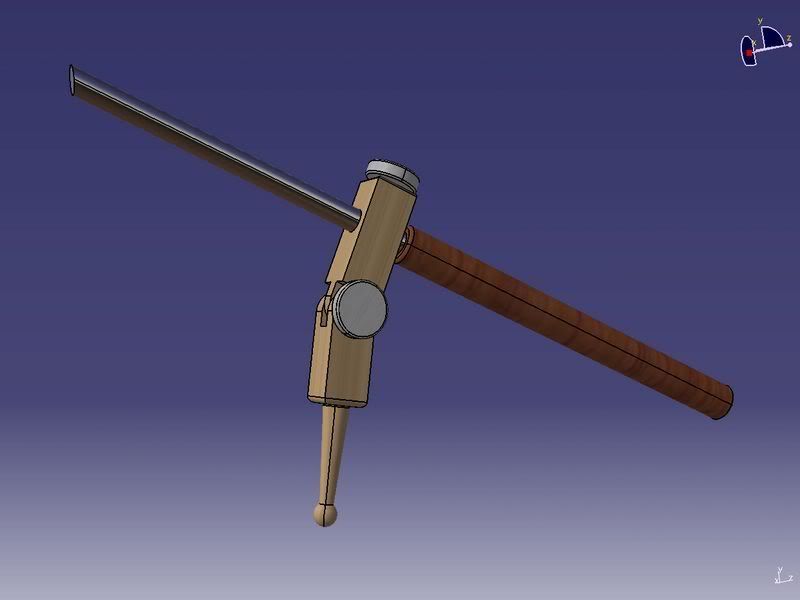

For me with different diameter tools I would prefer to have dedicated jigs that can be adjusted as the tools wear rather than to adjust for different gouges.

So...

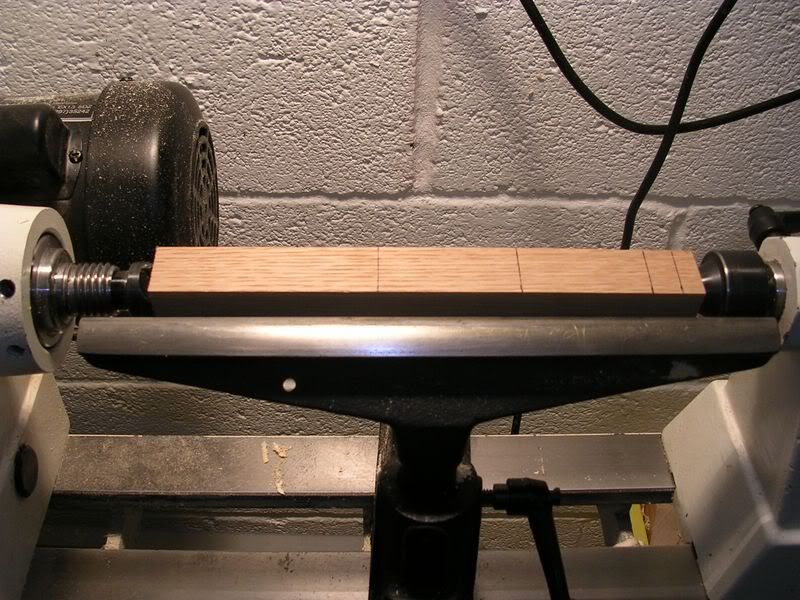

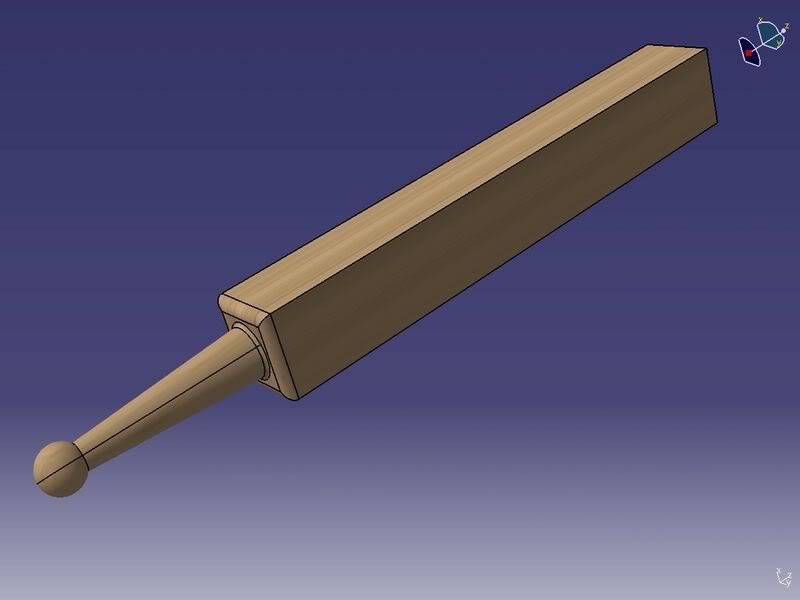

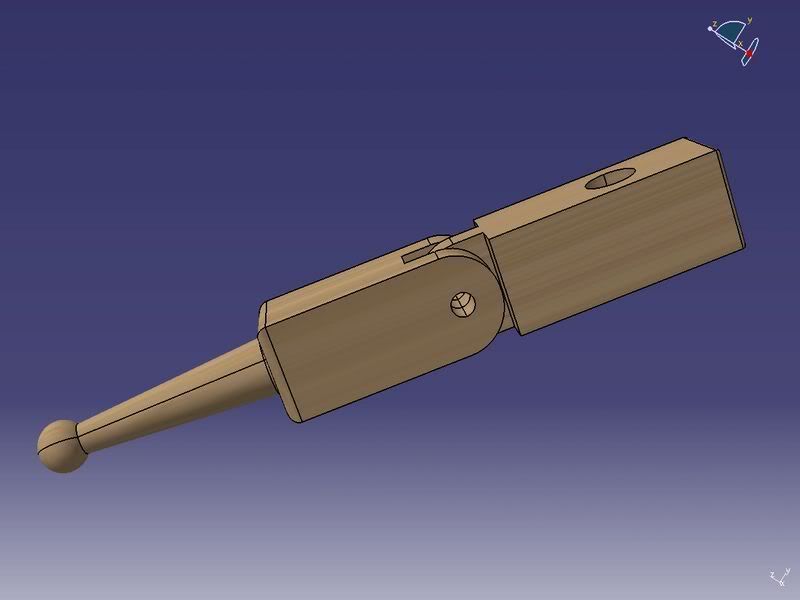

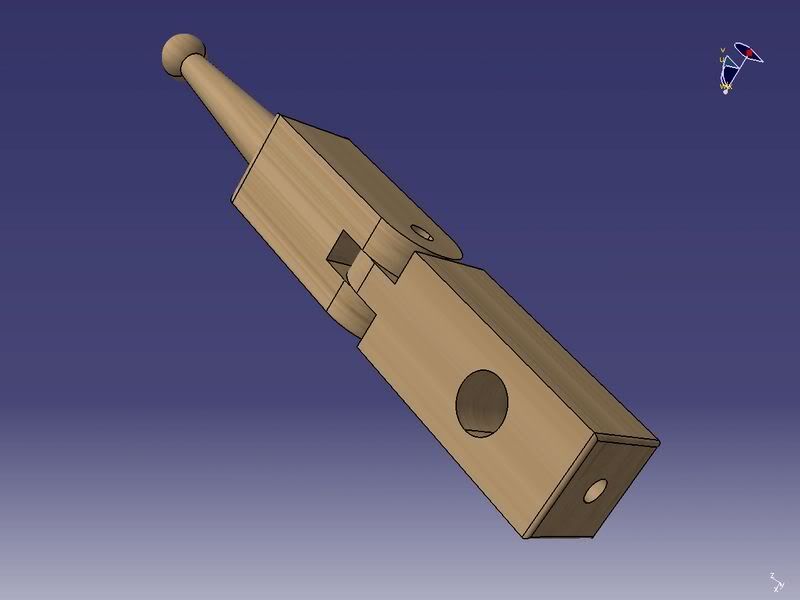

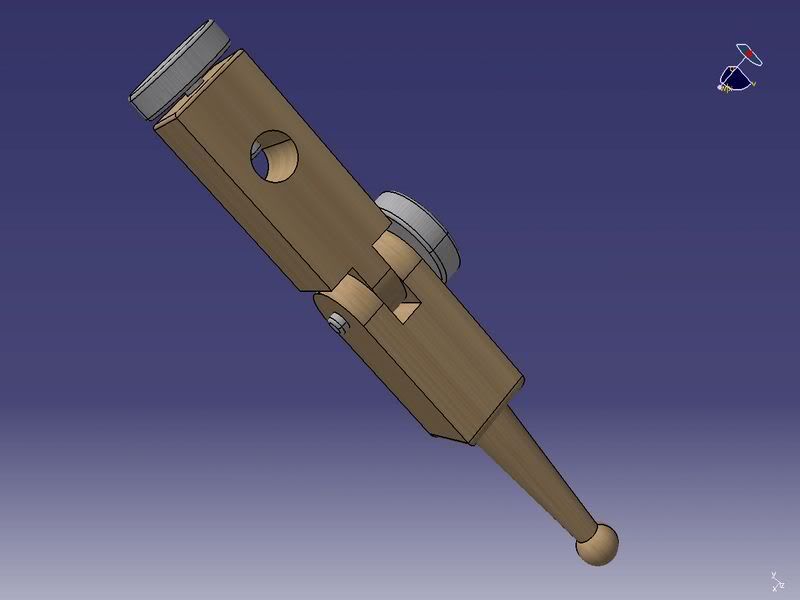

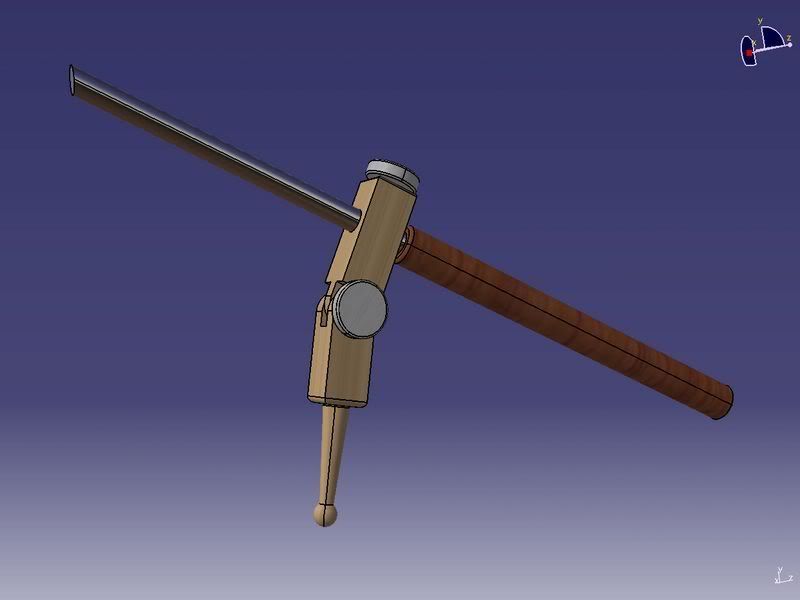

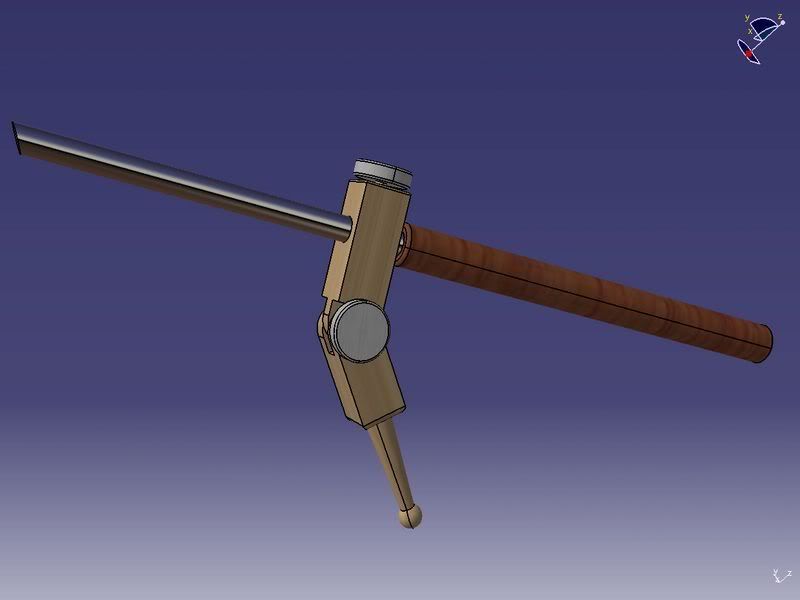

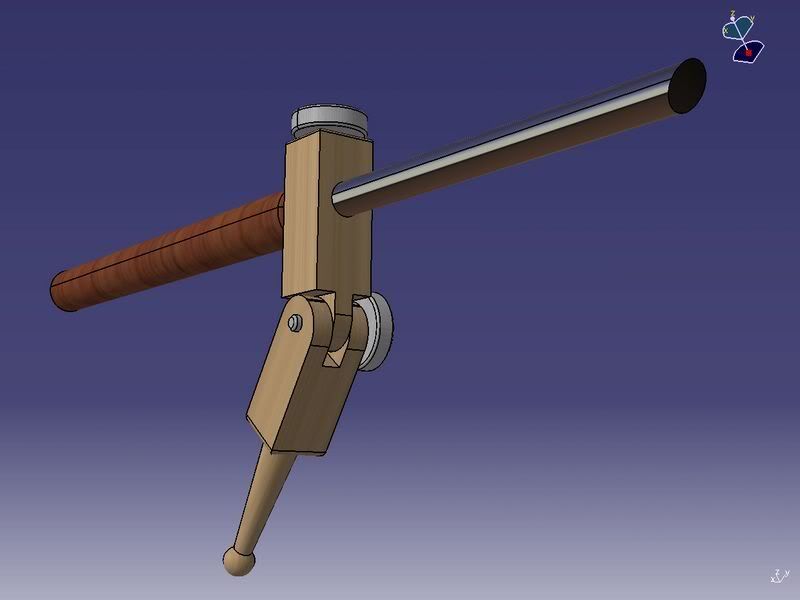

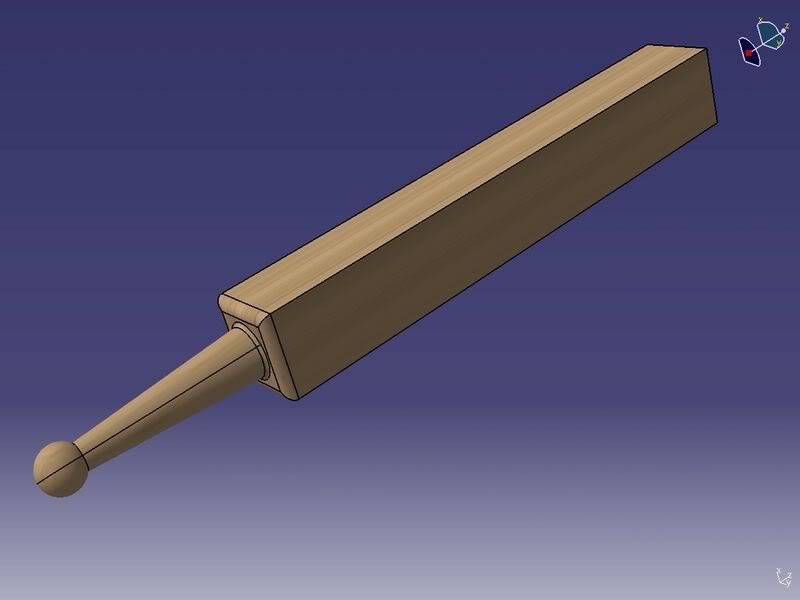

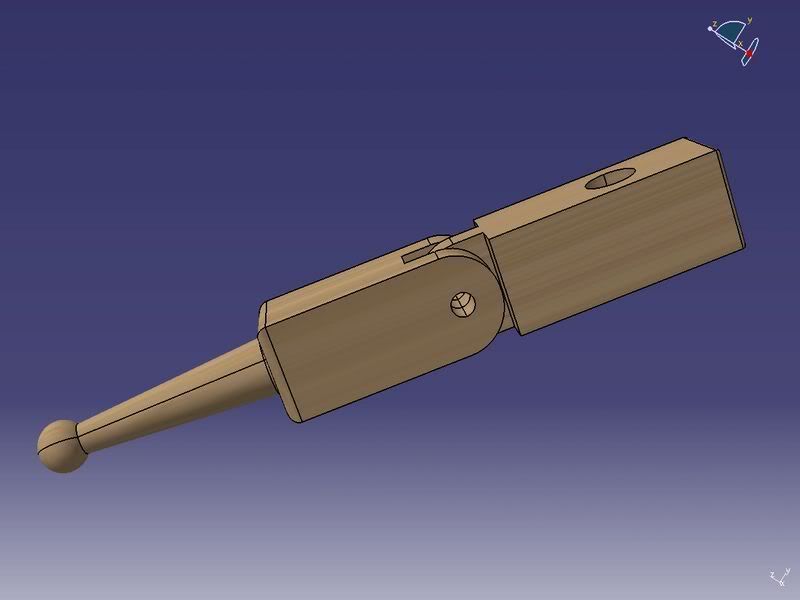

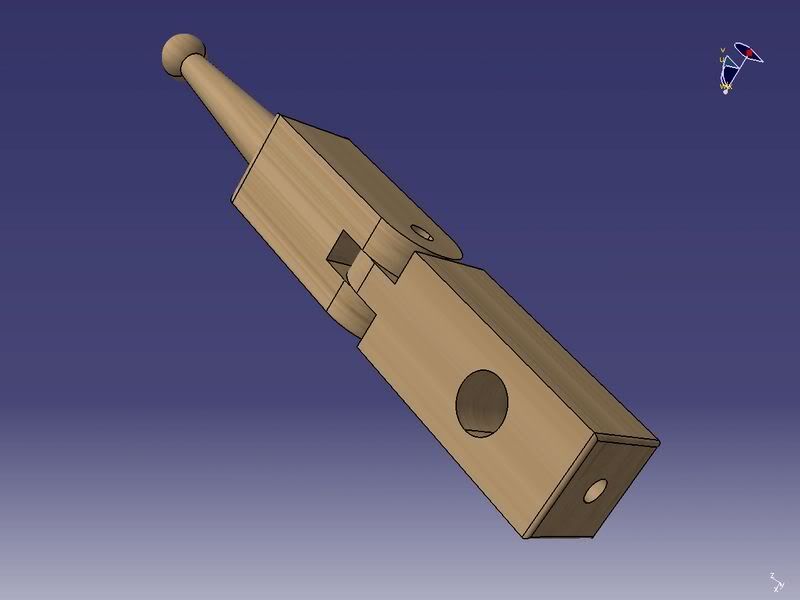

Take a piece of 25mm * 25mm wood and turn between centres the tapered post section including the 13mm ball at the bottom.

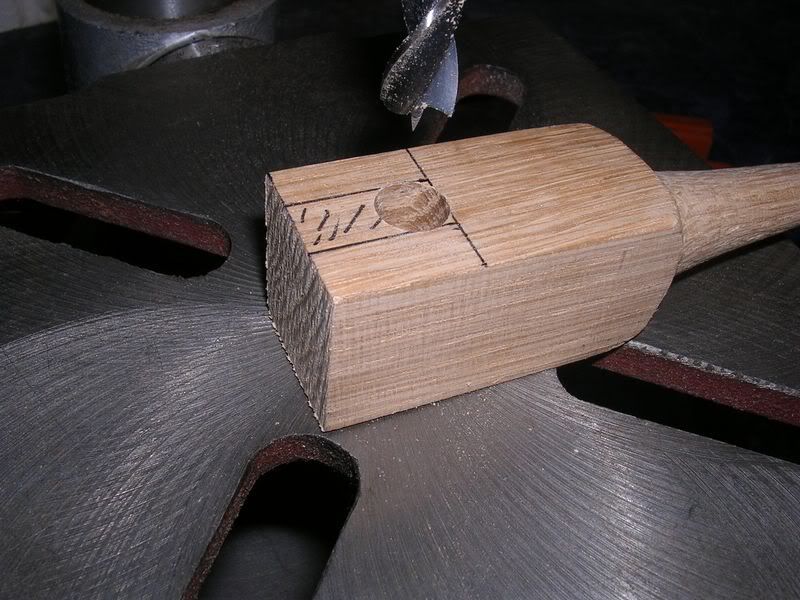

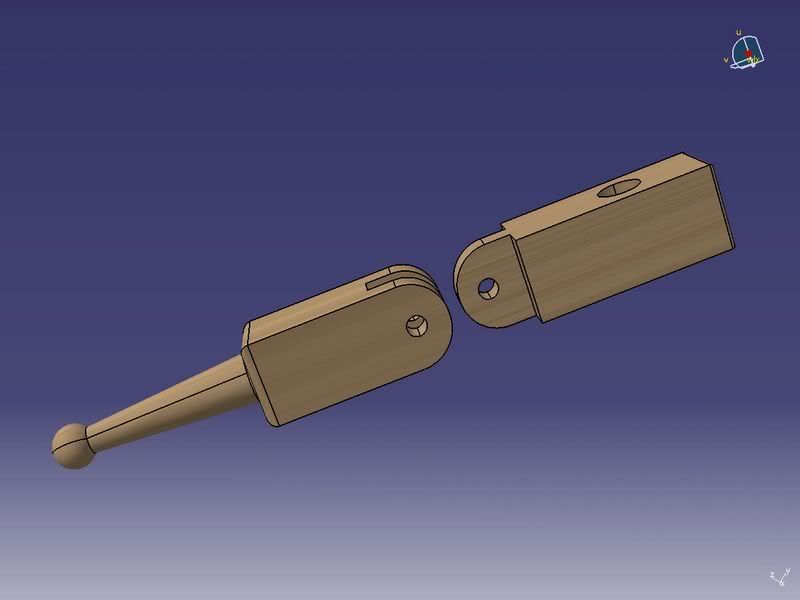

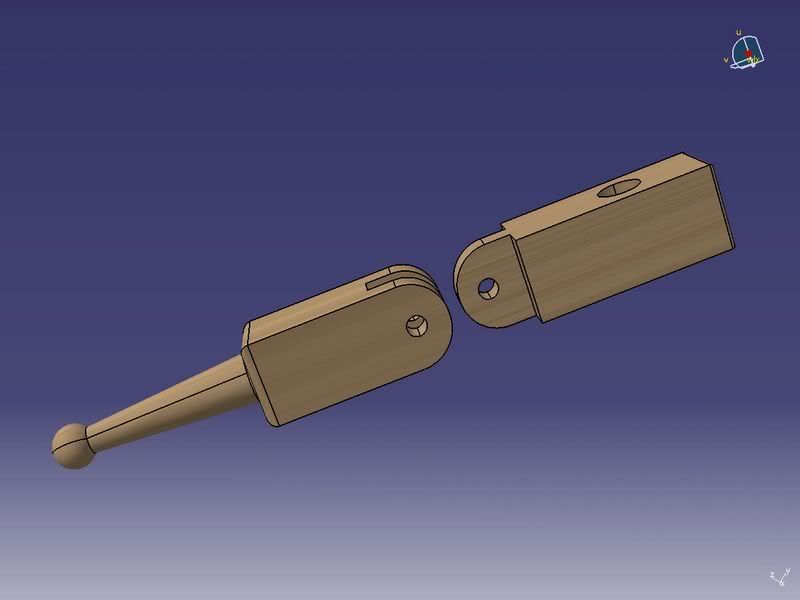

Remove this and cut in half. Giving us the post and tower section.

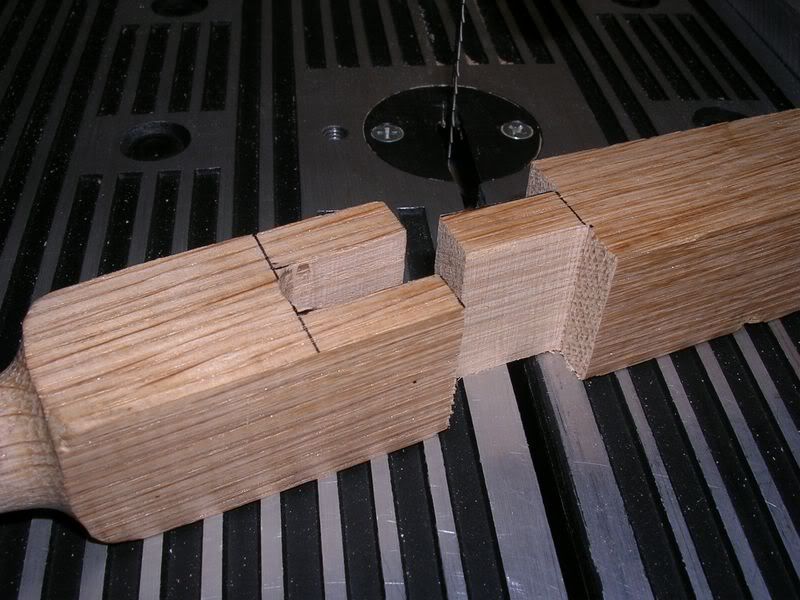

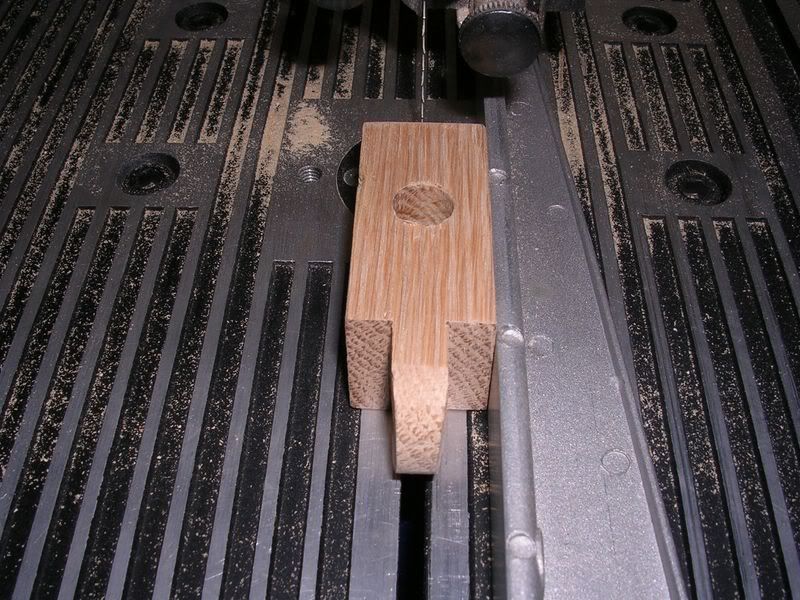

Notch the tower and post out. A bandsaw would be ideal for the slot.

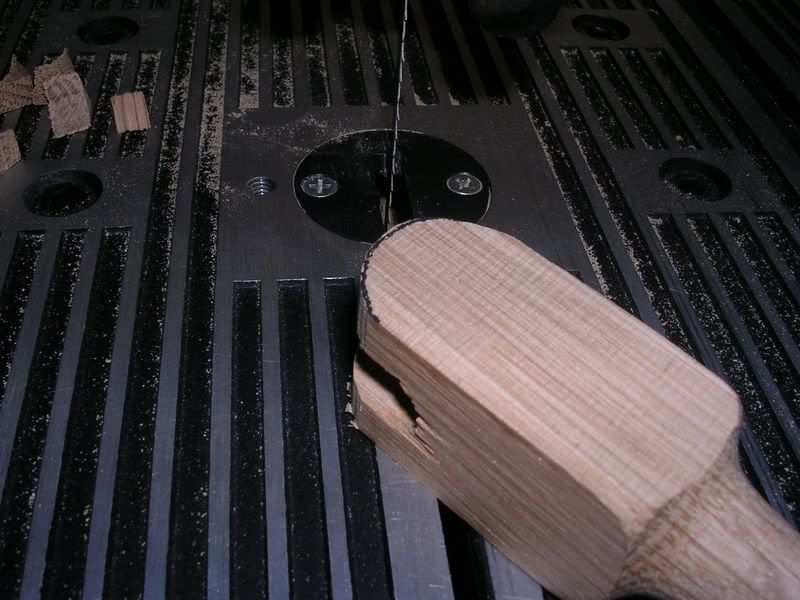

On the tower stem round over to ensure it rotates free in post.

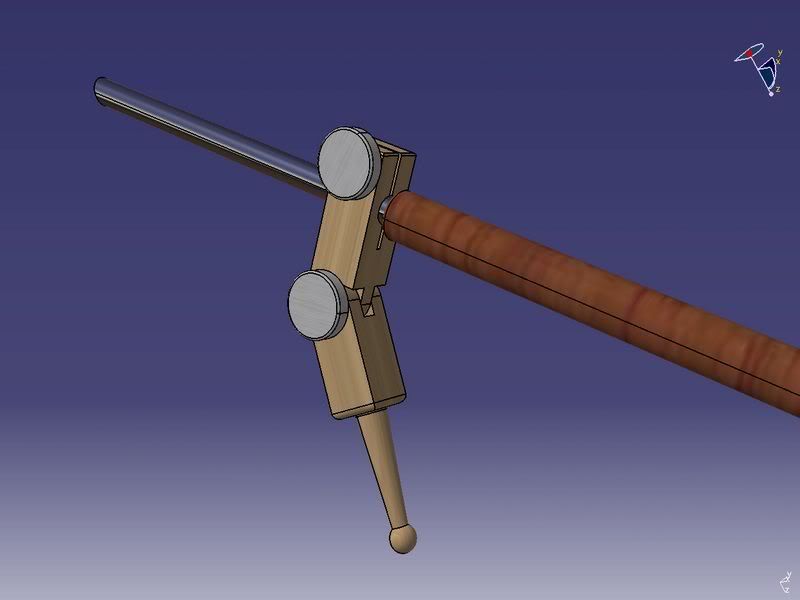

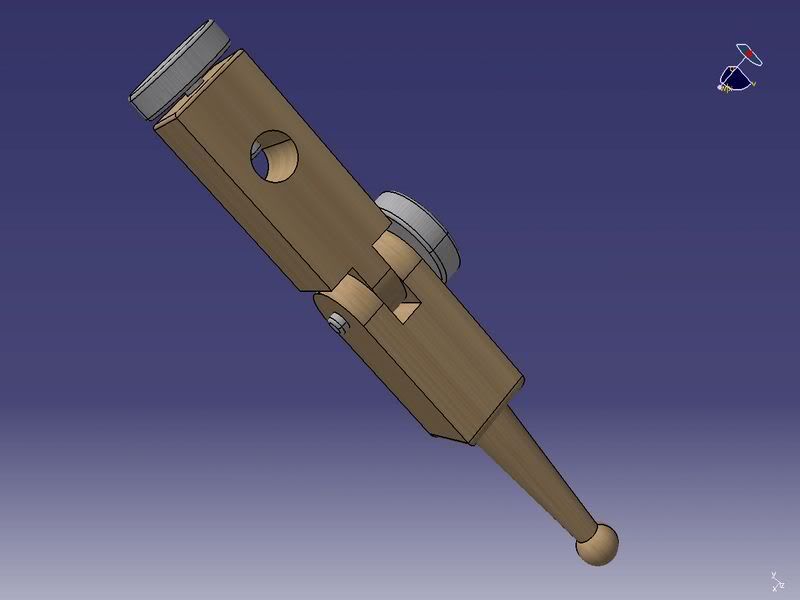

Push them together with a small gap at the bottom and drill a 6mm hole through pivot joint

Then drill the tower to a hole suitable for your gouge. And for the clampdown knob.

Using 6mm threaded inserts for the pivot joint and clampdown knob assemble together.

Adjust pivot knob to suit required angle. And use clampdown knob to hold gouge in position.

I have yet to build one but will have a go this week.

Cheers

Shaun

Continuing from a previous thread I thought I'd post an idea that I hope would be suitable for anyone to make.

Again it uses some of the fundamental ideas that Chas posted but really is as easy as could be to make. (I think!)

For me with different diameter tools I would prefer to have dedicated jigs that can be adjusted as the tools wear rather than to adjust for different gouges.

So...

Take a piece of 25mm * 25mm wood and turn between centres the tapered post section including the 13mm ball at the bottom.

Remove this and cut in half. Giving us the post and tower section.

Notch the tower and post out. A bandsaw would be ideal for the slot.

On the tower stem round over to ensure it rotates free in post.

Push them together with a small gap at the bottom and drill a 6mm hole through pivot joint

Then drill the tower to a hole suitable for your gouge. And for the clampdown knob.

Using 6mm threaded inserts for the pivot joint and clampdown knob assemble together.

Adjust pivot knob to suit required angle. And use clampdown knob to hold gouge in position.

I have yet to build one but will have a go this week.

Cheers

Shaun