As before, it is with some trepidation that I set foot on this area of the forum. Although I have been doing various projects using machinery over the years, it’s only recently that I have decided to try getting results using hand tools. As such, I’ve upgraded from just an old Stanley No. 4, tuned as best I can, to a new WoodRiver No. 5 and have been very pleased with the results. I’ve also laid my hands on a Veritas dovetail saw, very nice, as well as some Narex chisels, based on various recommendations. The chisels have been sharpened following the method using by Paul Sellers in his YouTube videos (I know that there will inevitably be some that have differing views to Paul but his method seemed to work for me).

Anyhow, the problem that I am coming up against is the use of knife walls when crosscutting. Paul’s, and others, videos show them using a combination or engineer’s square to mark across using a marking knife. The first cut is done gently and subsequent cuts more strongly. After that a chisel is used to chip out the initial wall before going on to use a chisel to deepen the wall.

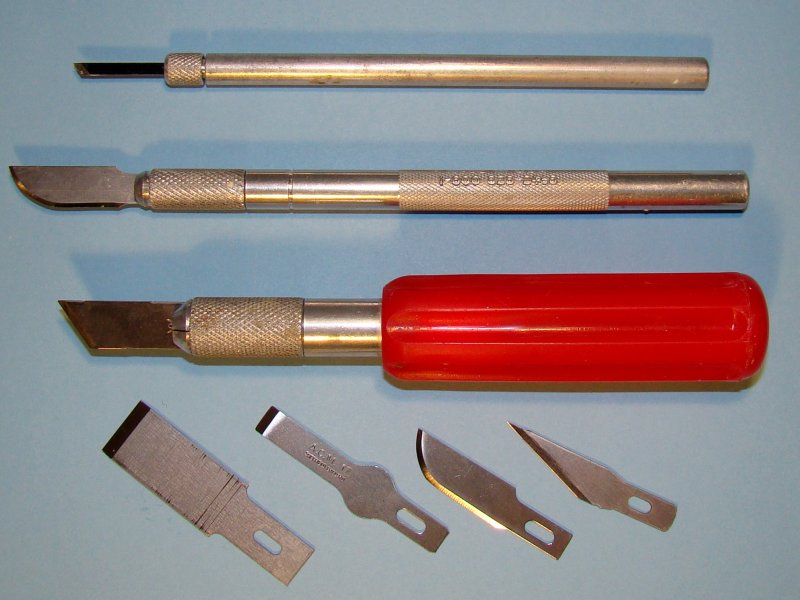

My problem seems to be getting a sufficient depth of cut at the initial stages. In Paul’s videos, he seems to be able to cut down a couple of millimetres just using the marking knife. I’m finding this very difficult. I have a choice of marking knives. Years ago I used to use a Stanley knife. Then I was persuaded by something I read to buy a Japanese V-point marking knife

http://www.axminster.co.uk/japanese-vee ... ife-384008

which gets very good reviews but I find difficult to hold (my technique being wrong?)

My final purchase, based on something I read by our one and only Peter Sefton, was a scalpel and I bought a Swann Morton No. 3 handle with 10A blades. I find this, too, difficult to hold and press down hard; it always feels as if the blade is going to snap. Again, it might be my technique.

Part of the problem with my technique may be that when trying to cut hard, I am worried about the knife slipping and cutting my thumb which is holding the edge of the square.

Any advice on the correct way to go about using a marking knife would be gratefully received.